External circulation system for CFB smoke generation equipment

A circulation system and flue gas generation technology, applied in the field of external circulation system, can solve the problems of large bed area, difficulty in large-scale, low flue gas velocity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

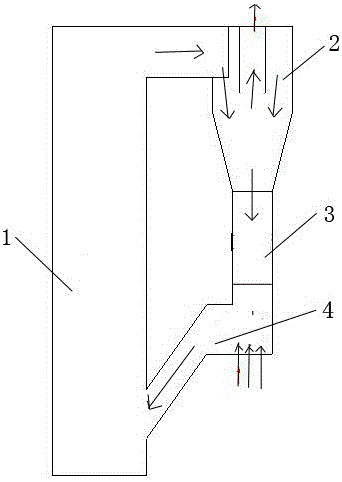

[0018] An external circulation system for CFB flue gas generating equipment, comprising an adiabatic gas-solid rotary separator 2 and a feeder 4 arranged at the bottom thereof and communicating with it.

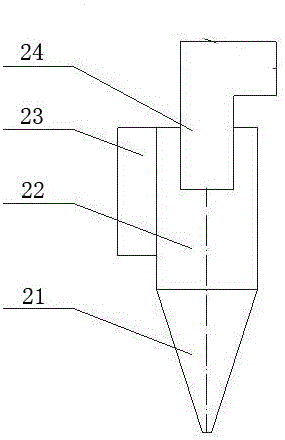

[0019] The adiabatic gas-solid rotary separator 2 is as figure 2 As shown, the main body is divided into an upper straight section 22 and a lower cone section 21, the side of the straight section 22 is provided with a flue gas inlet 23, and a central cylinder 24 is vertically arranged in the straight section 22, and the upper port of the central cylinder 23 is For flue gas outlet. The flue gas inlet 23 draws air from the flue gas outlet at the top of the combustion furnace 1, and the feeder 4 returns the collected solid particles to the combustion chamber of the combustion furnace 1 for re-combustion.

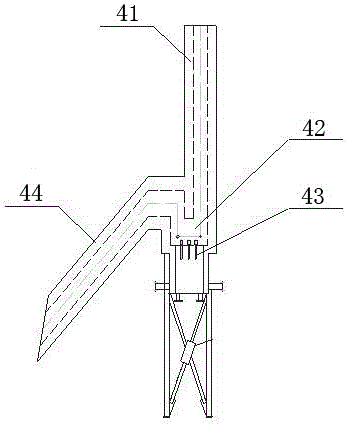

[0020] The feeder 4 is as image 3 As shown, it includes a feed pipe 41, a return valve 42 and a discharge pipe 44. The upper part of the feed pipe 41 communicates with the...

Embodiment 2

[0023] like figure 1 As shown, an external circulation system for CFB flue gas generating equipment includes an adiabatic gas-solid rotary separator 2 and a feeder 4 arranged at its bottom and communicated with it through a feed pipe 3 .

[0024] The adiabatic gas-solid rotary separator 2 is as figure 2 As shown, the main body is divided into an upper straight section 22 and a lower cone section 21, the side of the straight section 22 is provided with a flue gas inlet 23, and a central cylinder 24 is vertically arranged in the straight section 22, and the upper port of the central cylinder 23 is For flue gas outlet.

[0025] The feeder 4 is as image 3 As shown, it includes a feed pipe 41, a return valve 42 and a discharge pipe 44. The upper part of the feed pipe 41 communicates with the bottom of the adiabatic gas-solid rotary separator 2, and the return valve 42 is installed on the feed pipe 41. Bottom, and a number of air caps 43 leading to the outside are installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com