Overhauling line of water supply and drainage system

A technology for maintenance lines, water supply and drainage, applied to measuring devices, instruments, hand-held tools, etc., can solve the problems of low maintenance accuracy, troublesome maintenance procedures, and relying on manual labor, etc., to achieve automatic detection, accurate detection, placement and fixed simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

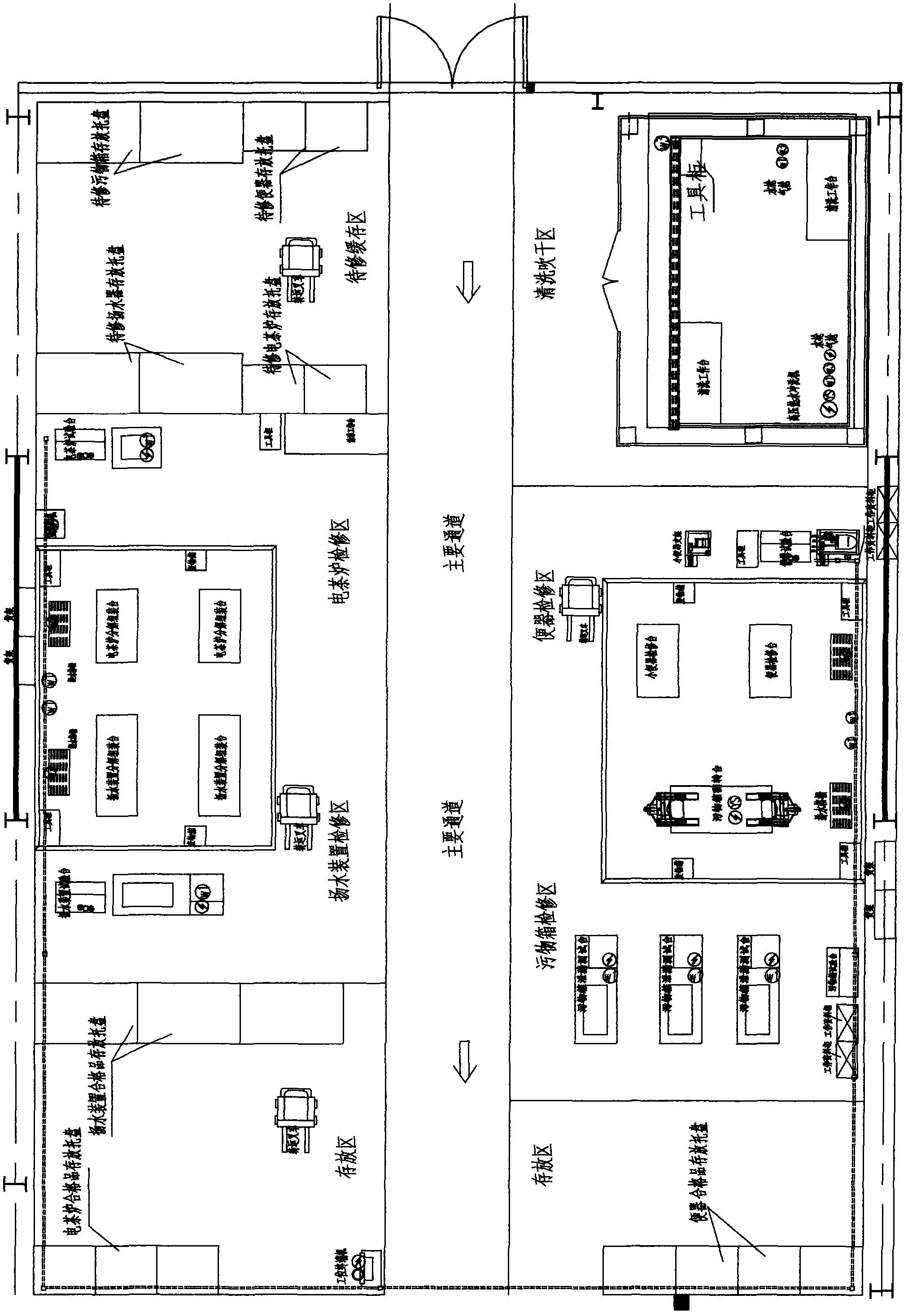

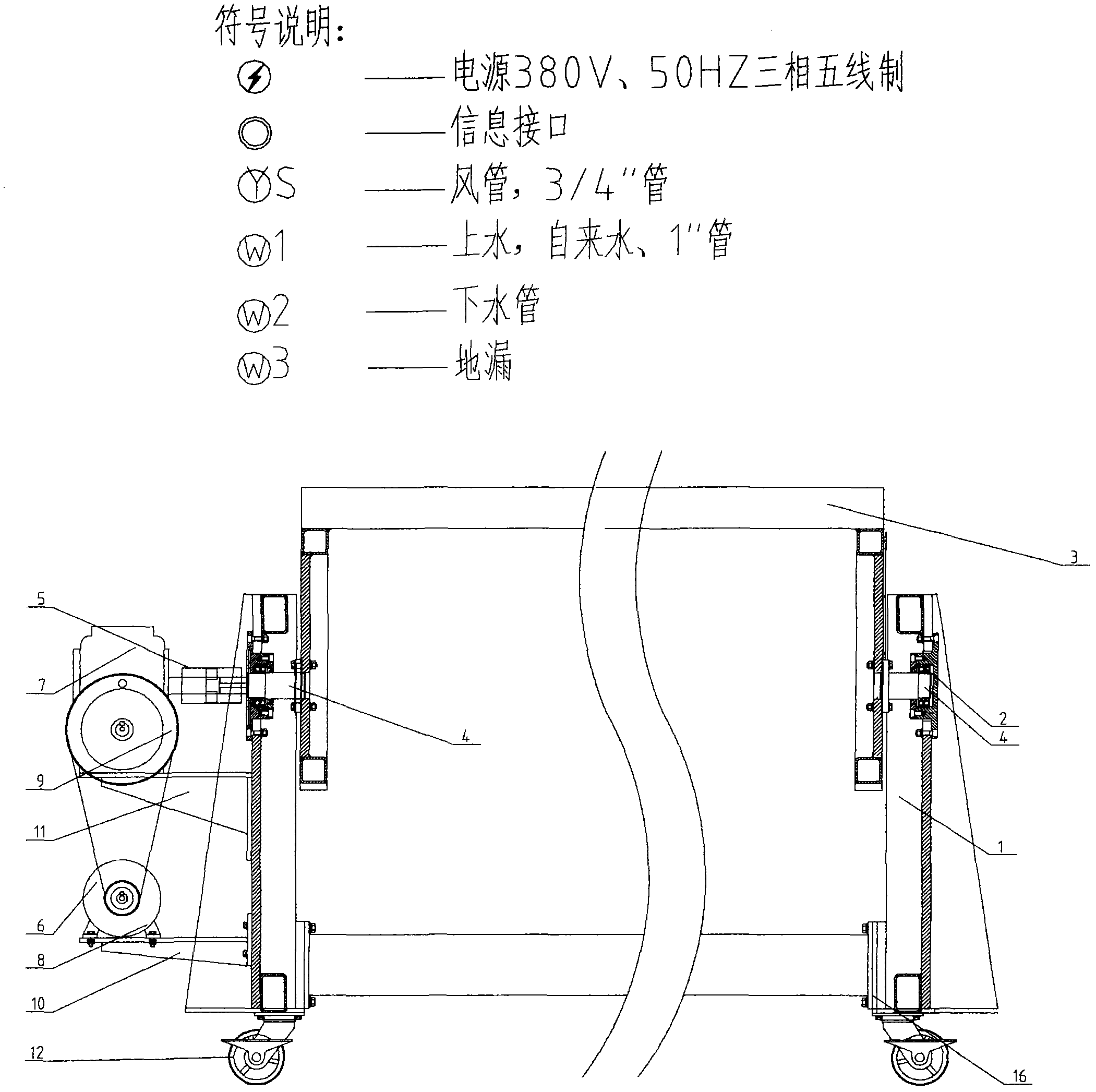

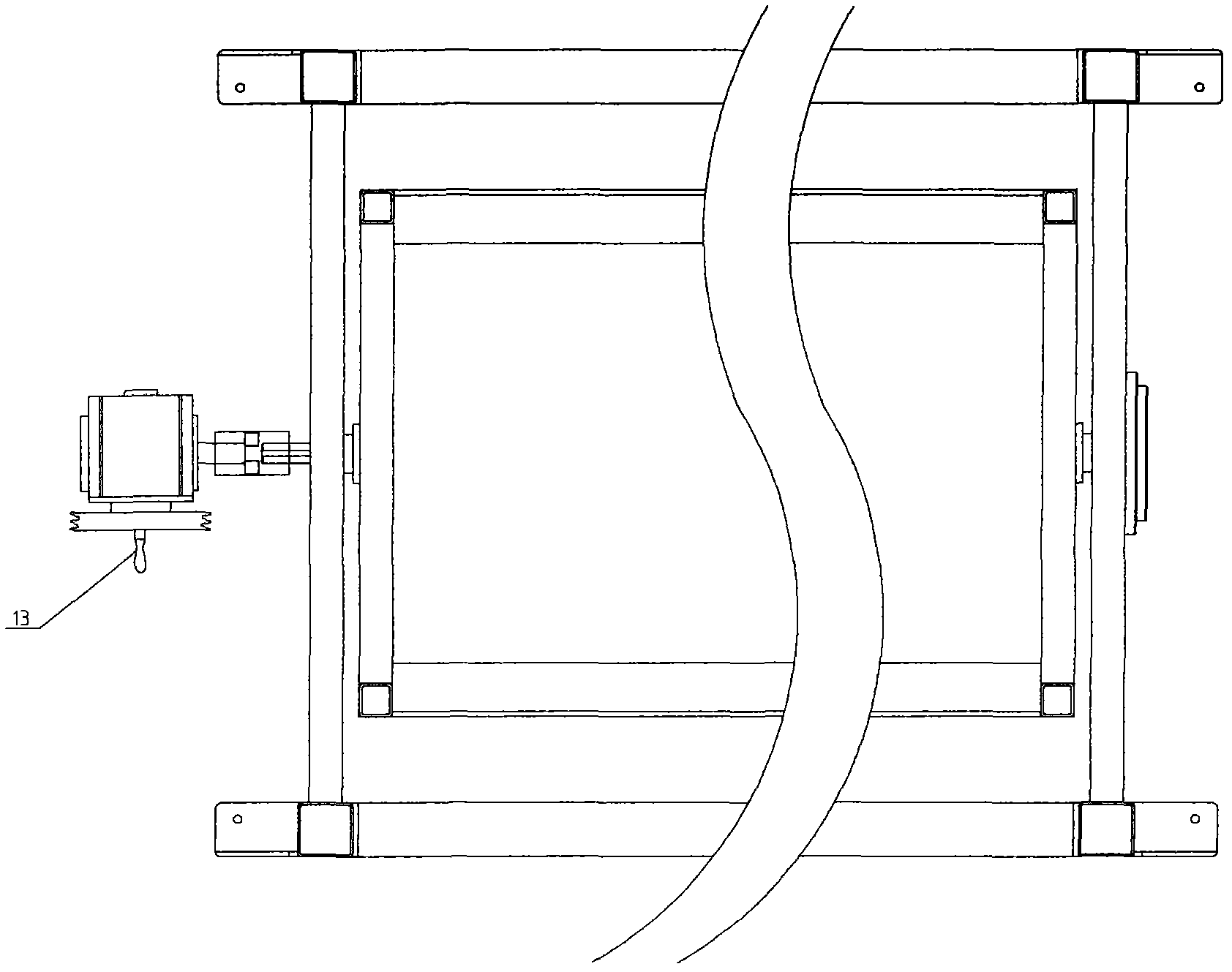

[0033] A water supply and drainage system maintenance line, the water supply and drainage system maintenance line includes two maintenance lines, one maintenance line includes a buffer area to be repaired, a water pumping device maintenance area, an electric tea stove maintenance area and a storage area, and the other maintenance line includes cleaning Drying area, dirt tank inspection area, toilet inspection area and storage area, the two inspection lines share a buffer area to be repaired; the buffer area to be repaired includes the storage tray for the pump to be repaired, the storage tray for the electric tea stove to be repaired, The storage tray for the dirt box to be repaired and the storage tray for the toilet to be repaired; the maintenance area of the electric tea stove includes the disassembly and assembly platform of the electric tea stove, the test bench for the electric tea stove, and is equipped with a waste box and a tool cabinet; the maintenance area of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com