Right angle type expansion bolt and screw automatic assembly device and defect detection method thereof

An automatic assembly device and technology of expansion bolts, which are applied in optical testing for flaws/defects, metal processing, metal processing equipment, etc., can solve the problems of poor stability, slow defect detection, and low production efficiency of right-angle expansion bolts, and improve the The effect of speed, saving labor cost and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

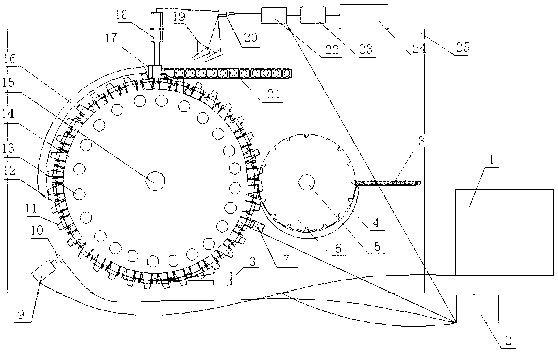

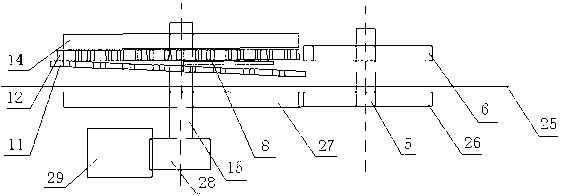

[0031] Such as figure 1 , figure 2 As shown, the present invention includes a computer 1, a PLC controller 2, a screw guide rail 3, a screw fixing piece 4, a first fixing shaft 5, a screw transmission plate 6, a through-beam photoelectric sensor 7, a finished product ejection mechanism 8, and a USB industrial camera 9. Ring LED light source 10, right-angle expansion bolt side fixing plate 11, screw embedded plate 12, fixing screw 13, cover plate 14, second fixed shaft 15, right-angle expansion bolt fixing piece 16, blocking piece 17, impact cylinder 18 , blowing port 19, tee interface 20, right-angle expansion bolt guide rail 21, solenoid valve 22, air source processing unit 23, air source 24, workbench 25, pinion 26, large gear 27, reducer 28 and motor 29; The motor 29 is connected with the reducer 28, the reducer 28 is connected with the second fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com