Single-way channel serially connected type end frame refrigeration device

A refrigerating device, series-type technology, applied in the direction of transportation and packaging, air handling equipment, aircraft parts, etc., can solve the problems of high cost requirements, interference with the normal operation of aircraft optical windows, and high technical difficulty, so as to avoid glass strength and avoid Aero-optical effect, low technical cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

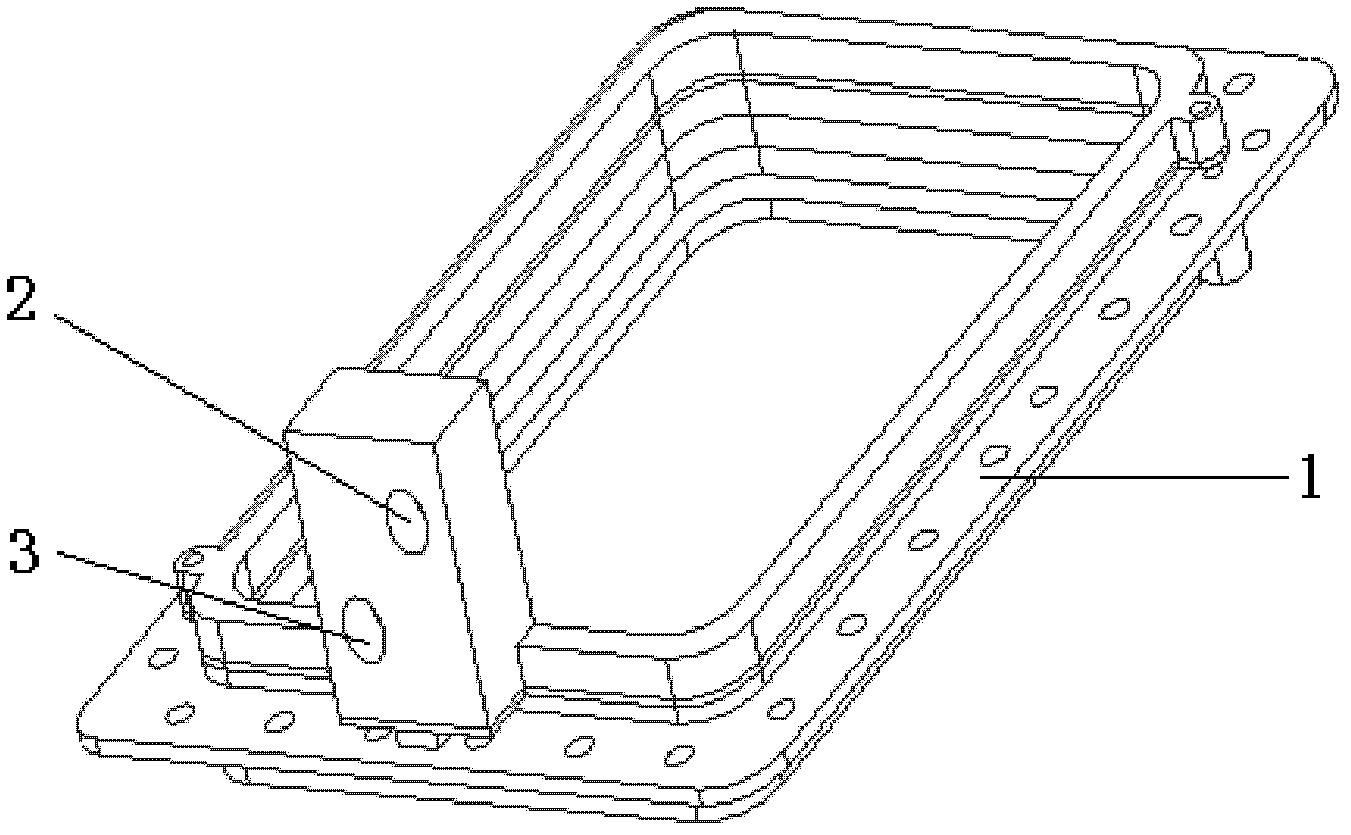

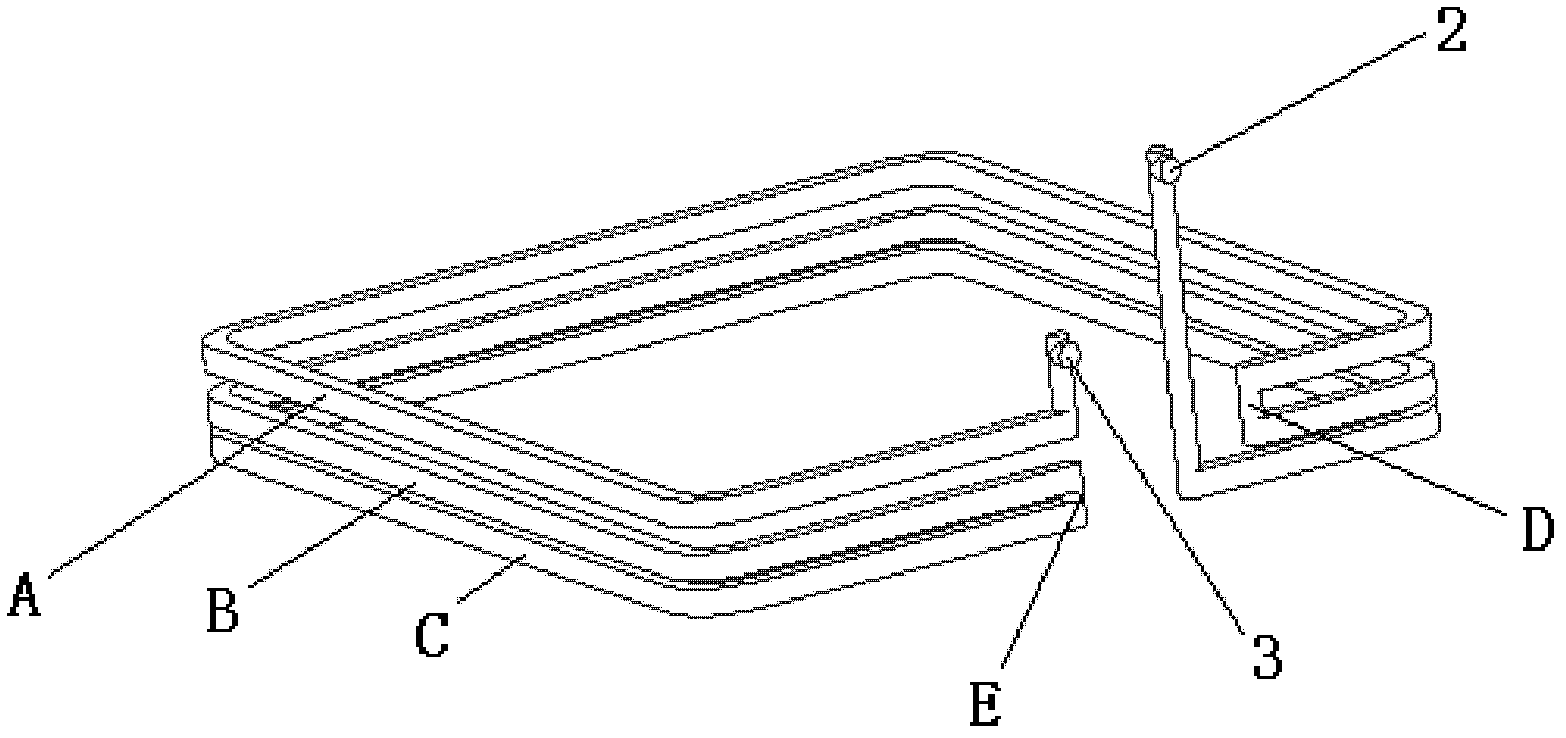

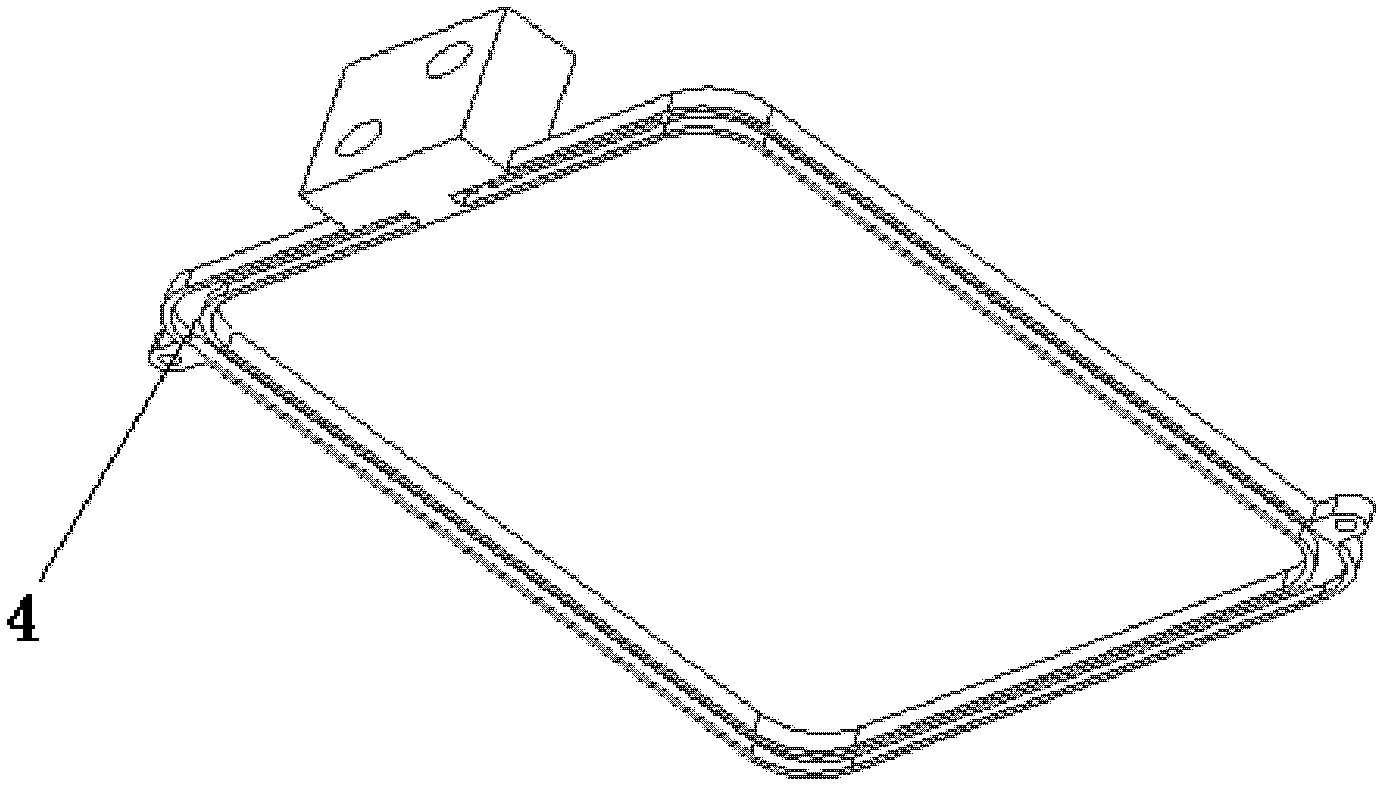

[0023] Such as figure 1 As shown, a one-way channel series end frame refrigeration device, the device includes a frame body 1, a liquid discharge outlet 2, a coolant inlet 3, and a coolant channel 4; its shape is a rectangle of 120mm×96mm , there are screw holes on the outer edge of the frame body 1, which are used to connect with the cooled parts; the frame body 1 is a layered structure, and each layer of the frame body 1 is engraved with an open back-shaped coolant channel 4, such as Figure 3-5 As shown, the size of the coolant channel 44 is 3×3mm, wherein the first layer of coolant channel 4 on the upper side opens downward on the reverse side, and the other layers of coolant channels 4 all open on the front side upward, and the layers pass through The salt bath brazing method is welded together, and the coolant channel 4 is sealed to form a zigzag sealed pipeline, such as figure 2 As shown; when the first layer and the second layer are welded, there is a clip in the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com