Air locking rotary feeding machine

A feeder and air lock technology, applied in packaging and other directions, can solve problems such as inability to lock air, pollution, waste of heat energy, etc., and achieve the effect of free rotation of air lock performance, enhanced air lock effect, and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

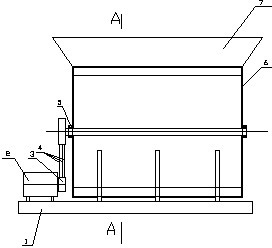

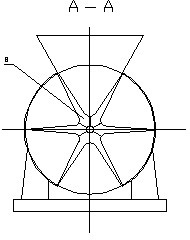

[0014] As shown in the drawings, the motor 2 and the housing 6 are installed on the chassis 1, and the motor 2 drives the rotor 8 to rotate through the pulley 3 and the belt 4. The rotor 8 is supported by the bearing mechanism 5 installed at both ends of the housing 6. The outer circle of the rotor 8 and the two side plates and the housing 6 are machined, and the gap is small (only 0.05-0.10mm) but it can rotate freely. The material falls from the hopper 7 and falls into the upper groove of the rotor 8 and fills the groove. When the groove turns to the lower part, the material falls from the groove into the equipment to complete the feeding process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com