Cow dung ash asphalt concrete pavement material and its preparation method

An asphalt concrete and pavement material technology, which is applied in the field of asphalt concrete pavement materials, can solve the problems of asphalt concrete pavement damage, insufficient cohesion, shortened service life, etc., and achieves the effects of improving the performance of asphalt concrete, improving performance indicators, and sufficient waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The raw materials of this embodiment are combined according to the following volume ratios. Limestone aggregate accounts for 89.3%;

[0029] The preparation method of the cow dung ash asphalt concrete material in this embodiment comprises the following steps: first calcining cow dung at a temperature of 500° C., cooling to room temperature, and sieving cow dung ash with a 0.075 mm square hole sieve; Cow dung ash is used instead of limestone powder, and cow dung ash and limestone powder are mixed evenly; limestone aggregate and road asphalt are stirred at 165°C, then the mixture of cow dung ash and limestone powder is added, and finally stirred evenly.

Embodiment 2~13

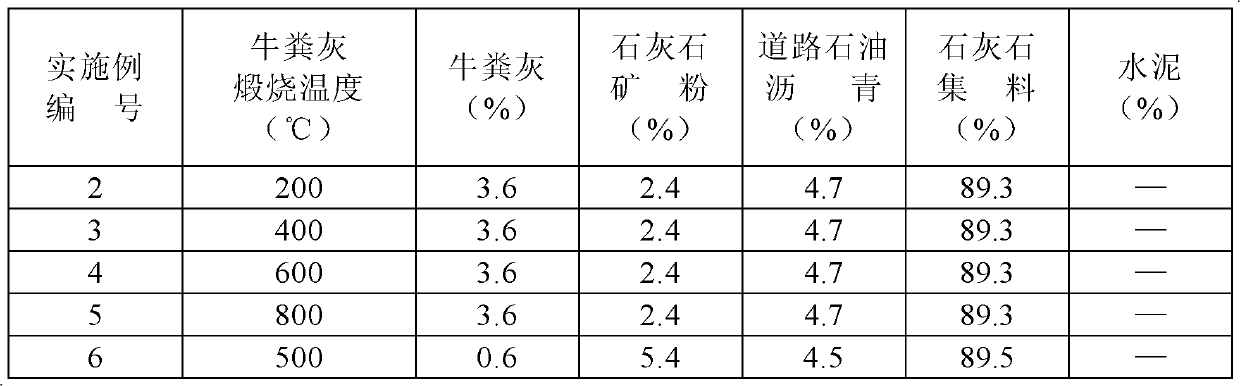

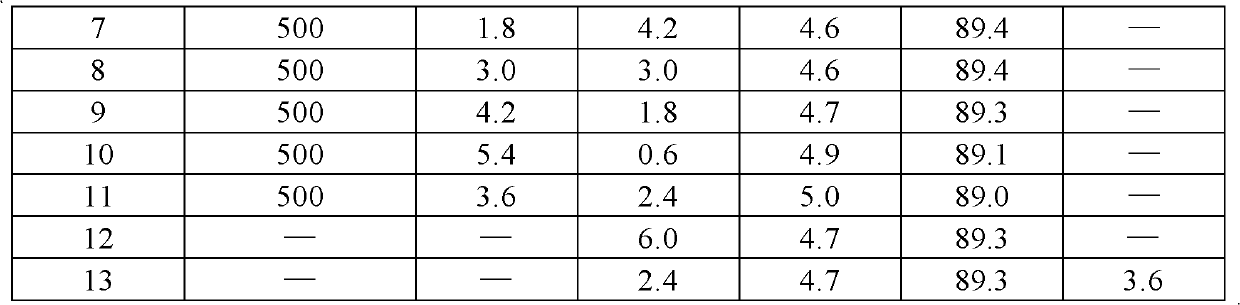

[0031] The asphalt concretes of Examples 2-13 were prepared according to the method described in Example 1, and the raw materials and their volume ratios are shown in Table 2.

[0032] Table 2 Asphalt concrete volume mix ratio

[0033]

[0034]

[0035] Test example:

[0036] The bituminous concrete specimens formed in Examples 1 to 13 were erected on the platform, and cooled at room temperature for 24 hours, and then carried out the Kenta fort of the concrete according to "Test Regulations for Asphalt and Bituminous Concrete in Highway Engineering" (JTJ052-2000). Road performance tests such as scattering loss, the test results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com