Two-component polyurethane grouting material for repair and maintenance of road and preparation method thereof

A two-component polyurethane and grouting material technology, which is applied in road repair, roads, roads, etc., can solve problems such as insufficient filling, easy blockage of grouting guns, and uplift of the road surface, so as to improve durability and construction efficiency , good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

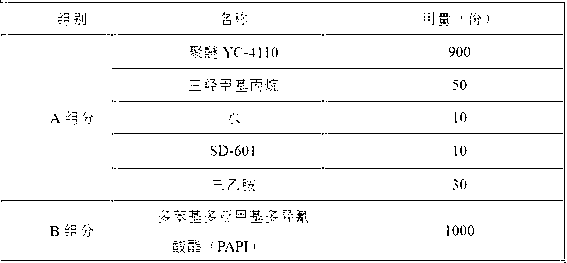

Embodiment 1

[0042]

[0043] The preparation method comprises the following steps:

[0044] In a reaction kettle equipped with a condenser and agitator, mix polyether YC-4110 and trimethylolpropane, start stirring evenly and heat up to 80°C, then add water, SD-601, and triethylamine to keep warm for a while Hours, drop the temperature and recover to obtain A component;

[0045] Stir and mix with component B at room temperature.

[0046] The volume began to expand after 50s, and the gel solidified after 120s; the mechanical performance test results showed that the compressive strength was 4.33MPa, the tensile shear strength was 1.89MPa, and the T-peel strength was 0.29 N / mm.

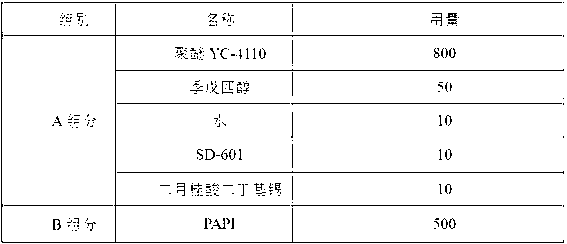

Embodiment 2

[0048]

[0049]Preparation method is identical with embodiment 1

[0050] The volume began to expand after 50s, and the gel solidified after 120s; the mechanical properties test results showed that the compressive strength was 2.87MPa, the tensile shear strength was 1.54MPa, and the T-peel strength was 0.22 N / mm.

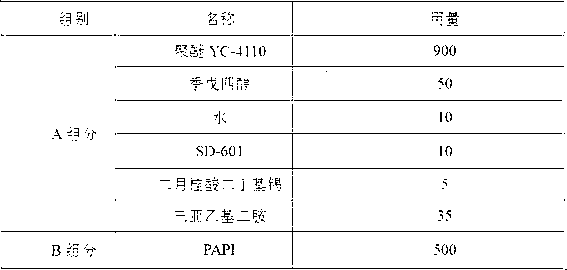

Embodiment 3

[0052]

[0053] The preparation method comprises the following steps:

[0054] Mix polyether YC-4110 and pentaerythritol, stir evenly and heat up to 100°C, then add water, SD-601, dibutyltin dilaurate and keep it warm for one hour, cool down and recover to obtain component A; mix with component B at room temperature Stir to combine well.

[0055] The volume began to expand after 25s, and the gel solidified after 60s; the mechanical performance test results showed that the compressive strength was 4.50MPa, the tensile shear strength was 2.71MPa, and the T-peel strength was 0.33N / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com