Guide flow cylinder, cylindrical bioreactor using guide flow cylinder and method for arranging guide flow cylinder

A technology of bioreactor and diversion cylinder, which is applied in specific-purpose bioreactor/fermenter, biochemical equipment and method, bioreactor/fermenter combination, etc. The production capacity of the reactor and the small effect of radial mixing can increase the chance of gas-liquid contact mass transfer, improve the utilization efficiency of light energy, and promote the effect of radial mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The draft tube of the present invention, the columnar bioreactor using the draft tube and its setting method will be described in detail below with reference to the embodiments and the accompanying drawings.

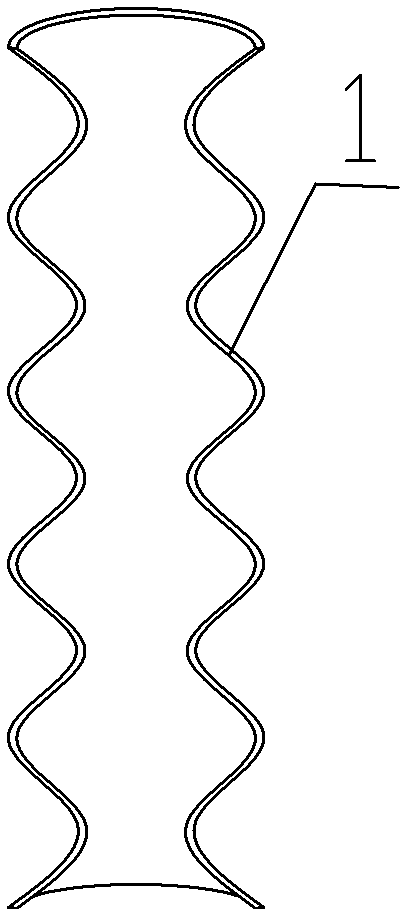

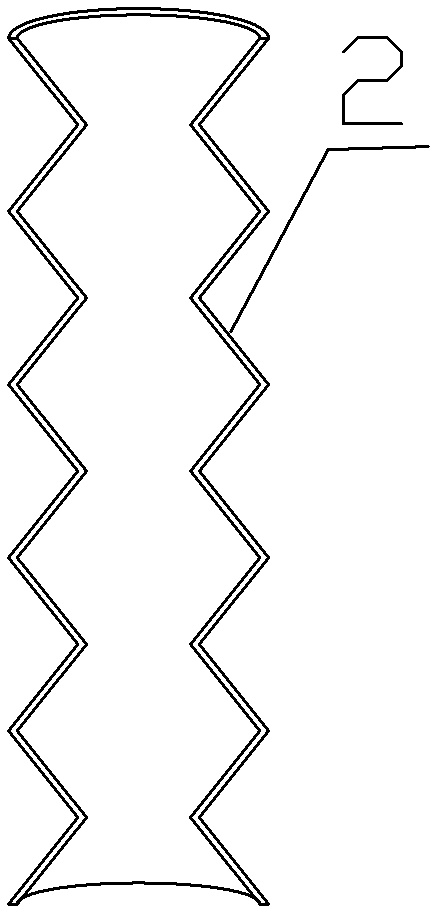

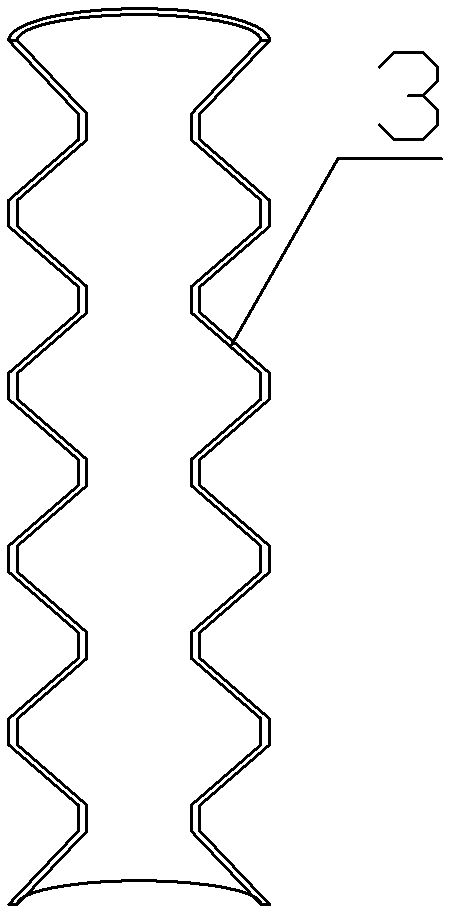

[0054] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the guide cylinder of the columnar bioreactor of the present invention, the guide cylinder is a wave-shaped structure guide cylinder 5 with a wall that penetrates up and down. The wave structure is one of arc wave structure 1 , triangular wave structure 2 , trapezoidal wave structure 3 and rectangular wave structure 4 . In the waves of the wave-shaped structure of the guide tube 5, there is a period between the peak point of the previous wave's highest peak and the peak point of the next wave's highest peak, and the described wave-shaped structure of the guide tube 5 has The waves range from 1.5 cycles to 50 cycles.

[0055] Such as Figure 5 ~ Figure 12 As shown, the columnar bioreactor wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com