A high coercive force, high energy product sintered NdFeB permanent magnet material and its preparation method

A technology with high magnetic energy product and high coercive force, which is applied in the fields of magnetic materials, inductor/transformer/magnet manufacturing, magnetic objects, etc., can solve the problem of not being able to obtain advantages, not exerting the synergistic effect of light rare earth and heavy rare earth, and deviation of actual composition, etc. Problems, to achieve the effect of increasing the number of mixing and mixing uniformity, enhancing the reliability and practicability of technology, and overcoming coercive force and magnetic energy product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

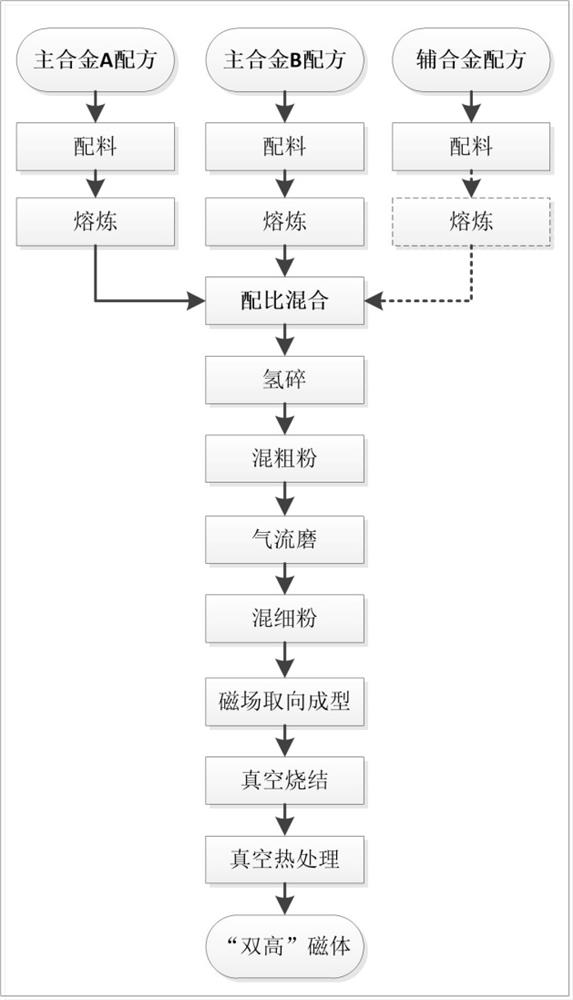

[0045] The design composition of the main alloy A is (Pr 0.25 Nd 0.75 ) 29 Fe 68.8 Co 1 Cu 0.1 Ga 0.2 B 0.9 (mass ratio), the design composition of the main alloy B is (Pr 0.25 Nd 0.75 ) 29 Dy 1 Fe 67.75 Co 1 Cu 0.1 Ga 0.15 B 1 (mass ratio), alloy flakes of 0.2~0.4mm are respectively made by batching, vacuum smelting and rapid-setting stripping; the design composition of auxiliary alloy C is (Pr 0.25 Nd 0.75 ) 50 Dy 30 Al 10 Zr 3 Nb 7 (mass ratio), alloy ingots are made by batching and vacuum smelting. The three alloys were sampled and tested to analyze their compositions. According to the analysis results, they were mixed in a ratio of A:B:C=65:34:1, and then loaded into a hydrogen crushing furnace to absorb hydrogen. Two rounds of "hydrogen absorption-dehydrogenation" process were adopted. Coarse powder is made, that is, firstly, under the hydrogen partial pressure of 0.15MPa, rotary hydrogen absorption is carried out for 0.5-1h, and the dehydrogenation...

Embodiment 2

[0047] The design composition of the main alloy A is (Pr 0.25 Nd 0.75 ) 29 Fe 68.8 Co 1 Cu 0.1 Ga 0.2 B 0.9 (mass ratio), the design composition of the main alloy B is (Pr 0.25 Nd 0.75 ) 29 Dy 1 Fe 67.75 Co 1 Cu 0.1 Ga 0.15 B 1 (mass ratio), alloy flakes of 0.2~0.4mm are respectively made by batching, vacuum smelting and rapid-setting stripping; the design composition of auxiliary alloy C is (Pr 0.25 Nd 0.75 ) 60 Dy 30 Al 10 (mass ratio), the design composition of auxiliary alloy D is Zr 30 Nb 70 (mass ratio), alloy ingots are made by batching and vacuum smelting. The four alloys were sampled and tested to analyze their compositions. According to the analysis results, they were mixed according to the ratio of A:B:C:D=65:34:0.9:0.1, put into a hydrogen crushing furnace to absorb hydrogen, and two rounds of "hydrogen absorption- Coarse powder is made by dehydrogenation process, that is, firstly, under the hydrogen partial pressure of 0.15MPa, rotate hydroge...

Embodiment 3

[0049] The design composition of the main alloy A is (Pr 0.25 Nd 0.75 ) 29 Fe 68.8 Co 1 Cu 0.1 Ga 0.2 B 0.9 (mass ratio), the design composition of the main alloy B1 is (Pr0.25 Nd 0.75 ) 29 Dy 0.7 Fe 68.05 Co 1 Cu 0.1 Ga 0.15 B 1 (mass ratio), the design composition of the main alloy B2 is (Pr 0.25 Nd 0.75 ) 29 Dy 1.5 Fe 67.25 Co 1 Cu 0.1 Ga 0.15 B 1 (mass ratio), alloy flakes of 0.2~0.4mm are respectively made by batching, vacuum smelting and rapid-setting stripping; the design composition of auxiliary alloy C is (Pr 0.25 Nd 0.75 ) 50 Dy 30 Al 10 Zr 3 Nb 7 (mass ratio), alloy ingots are made by batching and vacuum smelting. The four alloys were sampled and tested to analyze their compositions. According to the analysis results, they were mixed in the ratio of A:B1:B2:C=65:22:12:1, and then put into a hydrogen crushing furnace to absorb hydrogen. Two rounds of "hydrogen absorption- Coarse powder is made by dehydrogenation process, that is, firstly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com