Aluminum alloy silicon-free efficient degreasing fluid and preparation method thereof

A degreasing liquid and aluminum alloy technology, which is applied in the field of aluminum alloy surface treatment, can solve problems such as adhesion and difficulty in removal, and achieve the effect of convenient transportation and storage, and excellent decontamination and cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation method of the present invention is described in detail below, but not limited:

[0016] In the present invention, the degreasing liquid is prepared by uniformly mixing alkali metal hydroxide, phosphate, buffer, corrosion inhibitor, surfactant and water.

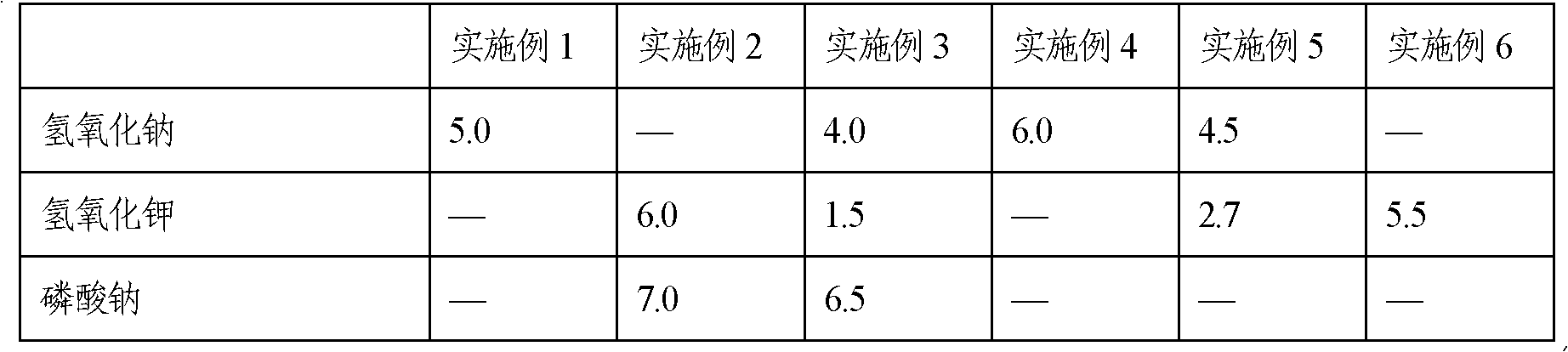

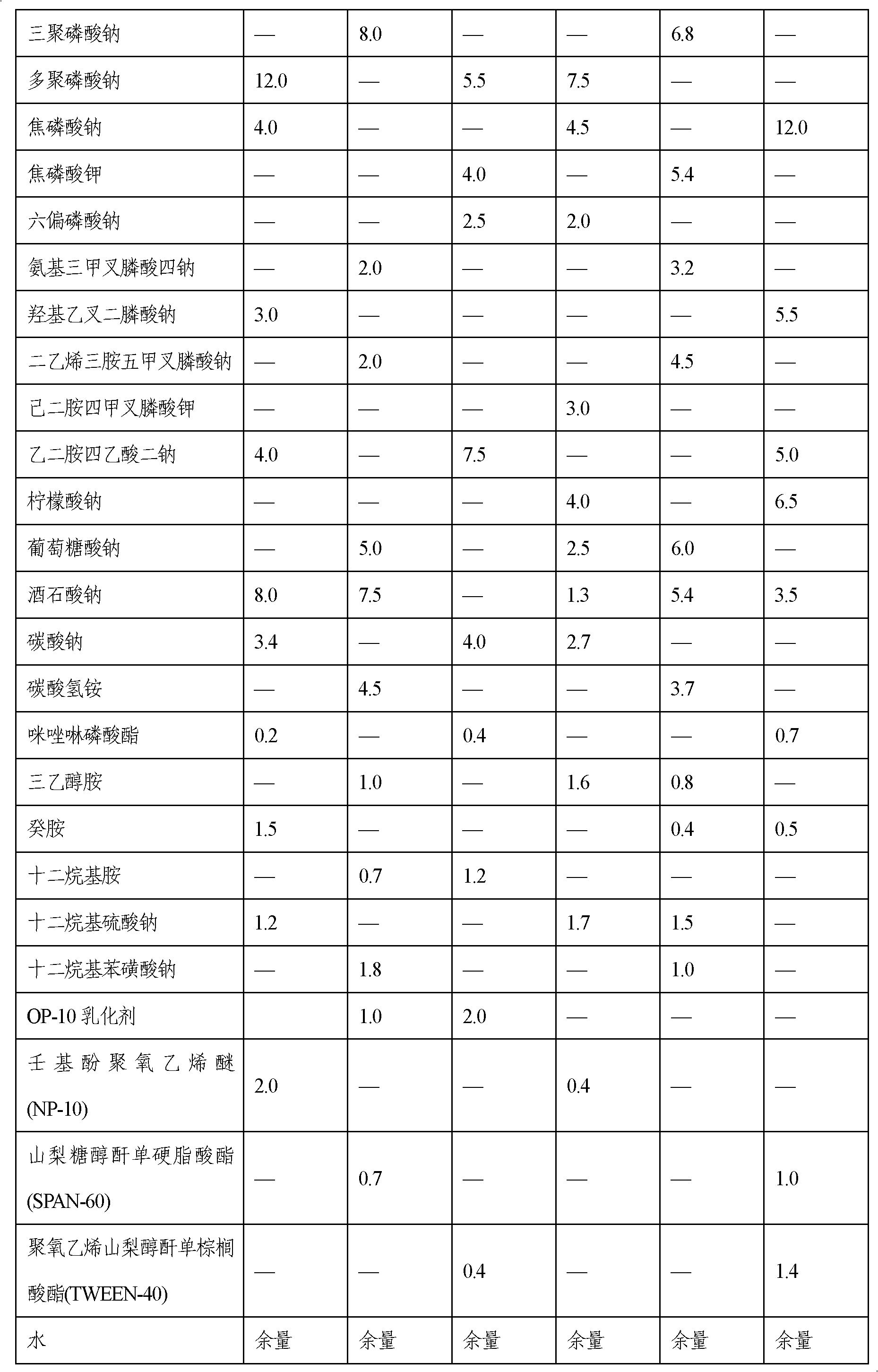

[0017] Table 1 (g / L)

[0018]

[0019]

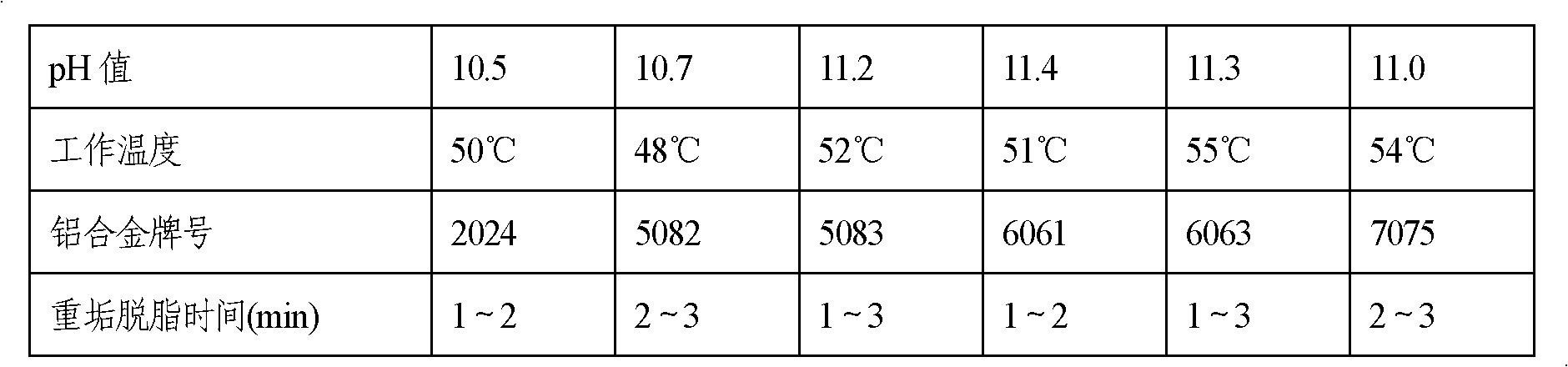

[0020]

[0021] Tests have proved that the aluminum alloy silicon-free high-efficiency degreasing liquid of the present invention can obtain good rapid decontamination and cleaning effects within the above-mentioned technical range. For the convenience of storage and transportation, the degreasing solution of the present invention can be prepared as a 3-5 times concentrated solution for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com