Fiber self-twisting hollow ingot in air-jet vortex spinning

A technology of hollow spindle and vortex spinning, which is applied to spinning machines, textiles, papermaking, and open-end spinning machines, etc. It can solve the problems of low yarn strength, achieve yarn strength improvement, expand application range, and increase strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

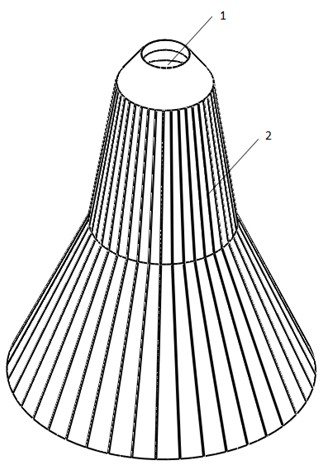

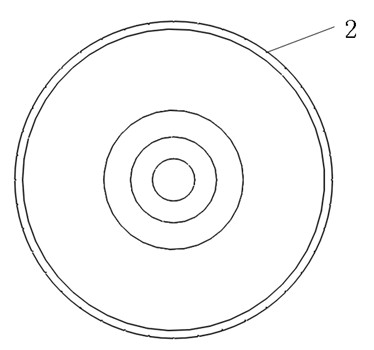

[0018] like figure 1 As shown, it is the three-dimensional rendering of air-jet vortex spinning fiber self-twisting hollow spindle, image 3 and Figure 4 Its bottom view and top view respectively, the air-jet vortex spinning fiber self-twisting hollow ingot includes a hollow ingot body, the outer surface of the hollow ingot body is evenly distributed with grooves 2, and one end of the hollow ingot body is a fiber inlet 1, The extending direction of the groove 2 is perpendicular to the tangential direction of the outer surface of the hollow ingot body.

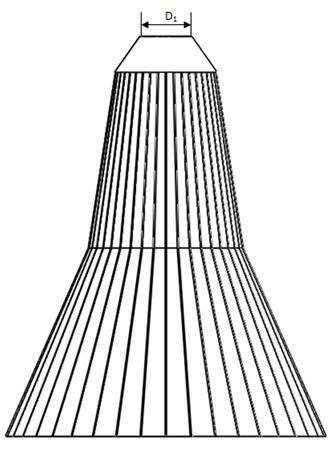

[0019] like figure 2 Shown is the front view of air-jet vortex spinning fiber self-twisting hollow spindle, the diameter of fiber inlet 1 is D 1 1.0mm.

[0020] like Figure 5 It is a partial diagram of the groove of the air-jet vortex spinning fiber self-twisting hollow spindle, Figure 6 In an enlarged view thereof, the groove width L of the groove 2 is 0.02mm, the groove height H is 0.03mm, and the groove number N...

Embodiment 2

[0022] like figure 1 As shown, it is the three-dimensional rendering of air-jet vortex spinning fiber self-twisting hollow spindle, image 3 and Figure 4 Its bottom view and top view respectively, the air-jet vortex spinning fiber self-twisting hollow ingot includes a hollow ingot body, the outer surface of the hollow ingot body is evenly distributed with grooves 2, and one end of the hollow ingot body is a fiber inlet 1, The extending direction of the groove 2 is perpendicular to the tangential direction of the outer surface of the hollow ingot body.

[0023] like figure 2 Shown is the front view of air-jet vortex spinning fiber self-twisting hollow spindle, the diameter of fiber inlet 1 is D 1 is 1.2mm.

[0024] like Figure 5 It is a partial diagram of the groove of the air-jet vortex spinning fiber self-twisting hollow spindle, Figure 6 In its enlarged view, the groove width L of the groove 2 is 0.03mm, the groove height H is 0.05mm, and the groove number N is ...

Embodiment 3

[0026] like figure 1 As shown, it is the three-dimensional rendering of air-jet vortex spinning fiber self-twisting hollow spindle, image 3 and Figure 4 Its bottom view and top view respectively, the air-jet vortex spinning fiber self-twisting hollow ingot includes a hollow ingot body, the outer surface of the hollow ingot body is evenly distributed with grooves 2, and one end of the hollow ingot body is a fiber inlet 1, The extending direction of the groove 2 is perpendicular to the tangential direction of the outer surface of the hollow ingot body.

[0027] like figure 2 Shown is the front view of air-jet vortex spinning fiber self-twisting hollow spindle, the diameter of fiber inlet 1 is D 1 is 1.4mm.

[0028] like Figure 5 It is a partial diagram of the groove of the air-jet vortex spinning fiber self-twisting hollow spindle, Figure 6 In its enlarged view, the groove width L of the groove 2 is 0.03 mm, the groove height H is 0.06 mm, and the number N of groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com