Pile sinking method for prestress hollow pipe piles by aid of follow-up sleeve

A hollow tube, prestressed technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of reduced construction efficiency, prolonged construction period, and many front and rear connection processes, etc., to achieve high construction efficiency, short construction period, easy to use The effect of hole cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

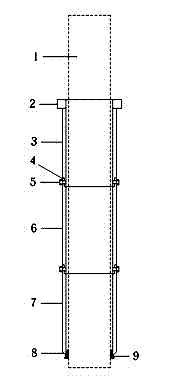

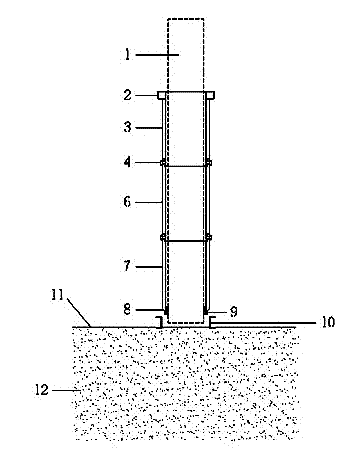

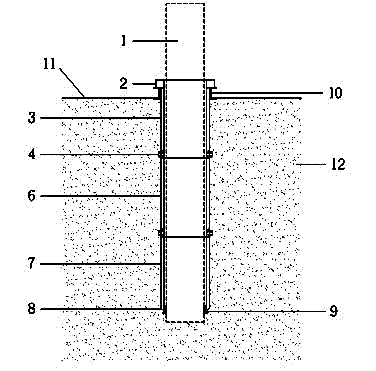

[0031] Example 1: see Figure 1-4 , the prestressed hollow tubular pile driving sleeve pile sinking method includes the following steps:

[0032] 1.1 Several sections of steel sleeves are connected by bolts to form a combined sleeve, placed on the front end of the prestressed hollow pipe pile 1, and then a steel beam 10 with the same inner ring shape as the outer ring shape is placed outside the combined sleeve, and then through the holding pressure Pile driver, press the conjoined sleeve into the soil together with the hollow pipe pile 1;

[0033] 1.2 Through the steel beam 10, clamp the combined sleeve pressed into the soil to a predetermined depth to keep it at a fixed position, and then lift the clamping mechanism of the holding pressure pile driver back to its position;

[0034] 1.3 Install the pile feeder on the clamping mechanism of the holding pressure pile driver, and then directly act on the top of the hollow pipe pile 1 with the pile feeder, and push the hollow pip...

Embodiment 2

[0038] Example 2: see Figure 1-4 , The prestressed hollow pipe pile driving sleeve pile driving method is the same as that of embodiment 1, the combined sleeve is provided with 3 sections connecting the long section sleeve 6, and the inner diameter of each sleeve is 10mm larger than the outer diameter of the prefabricated hollow pipe pile.

Embodiment 3

[0039] Embodiment 3: see Figure 1-4 , the prestressed hollow pipe pile follower sleeve pile sinking method is the same as embodiment 1, the combined sleeve is provided with 2 sections connecting the long section sleeve 6, and the inner diameter of each sleeve is 20mm larger than the outer diameter of the prefabricated hollow pipe pile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com