Unlimited layer fracturing process

A process method and layer-limited technology, applied in the field of unlimited layer fracturing technology, can solve the problems of limited number of fracturing layers, low operation efficiency, high construction risk, etc., achieve convenient use, simple string structure, and improve fracturing effect and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

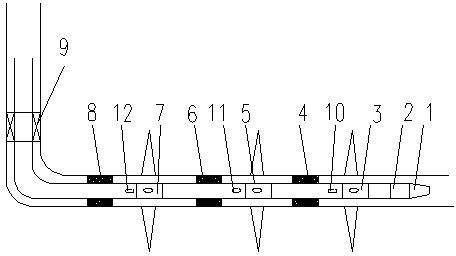

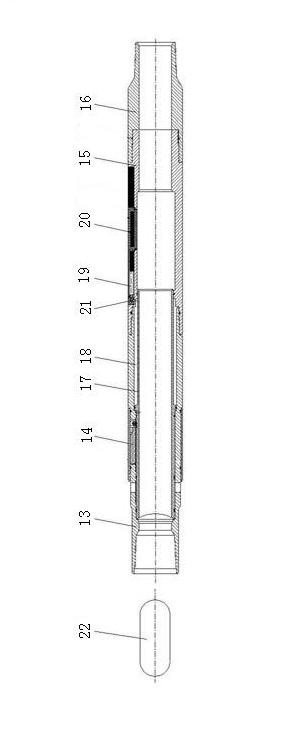

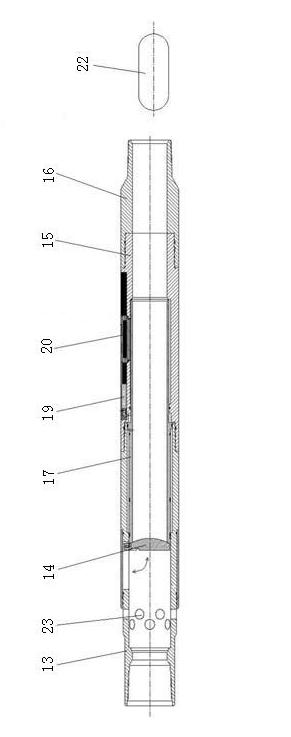

[0016] Such as figure 1 As shown, a kind of unlimited layer fracturing process method provided by the present invention, taking 3 layers of fracturing as an example, includes the following steps:

[0017] (1) To make the fracturing process string, the guide plug 1, the seat seal ball seat 2, the 1st stage unlimited layer fracturing sliding sleeve 3, the packer 4, the pipe string telescopic compensator, and the 2nd stage unlimited lamination Fracture sleeve 5, packer 6, pipe string telescopic compensator, 3-stage unlimited fracturing sleeve 7, packer 8, hanger 9 are connected sequentially from bottom to top to form a string;

[0018] (2) Send the tubing string made in step (1) to the predetermined setting position, set all the packers at once, then set the hanger 9, throw 1-level signal ball 10, and open the 1-level with no layer limit Fracturing sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com