Manual barring device

A manual turning and positioning device technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of high labor intensity, difficult to adjust, and high cost, and achieves low effort to rotate the flywheel, easy maintenance, and manufacturing costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

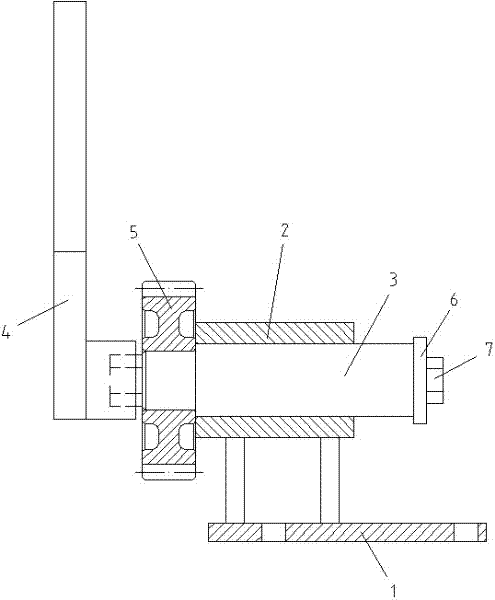

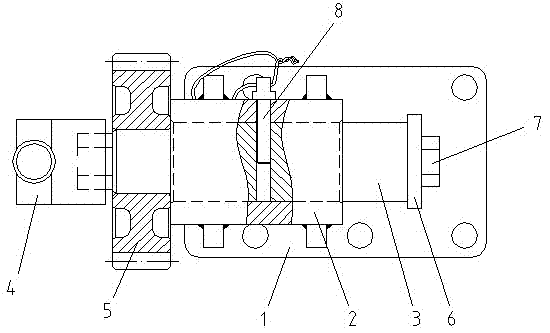

[0018] figure 1 It is a front structural schematic diagram of the manual barring device of the present invention; figure 2 for figure 1 Schematic diagram of the top view structure.

[0019] As shown in the figure, the manual barring device of this embodiment includes a support base 1, a shaft sleeve 2 arranged on the support base 1, and a shaft 3 that is rotatably matched with the shaft sleeve 2 and can slide axially along it, and one end of the shaft 3 A limit device is provided to prevent the shaft from slipping out of the sleeve 2 in the axial direction. The other end of the shaft 3 is detachably provided with a handle rod 4 for driving the shaft to rotate. The shaft section between the handle rod 4 and the sleeve 2 A gear 5 coaxial with the shaft is arranged on the top, and a positioning device for positioning the axial position of the shaft 3 in the sleeve is also included, and the positioning device is detachably connected with the shaft 3 .

[0020] Fix the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com