Processing method for ball bearing with ultra-thin wall and uniform section

A technology of equal cross-section and ball bearings, which is applied in the field of bearing processing, can solve the problems of high processing difficulty and achieve the effects of reduced deformation, enhanced rigidity, enhanced feasibility and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention are described with reference to the accompanying drawings.

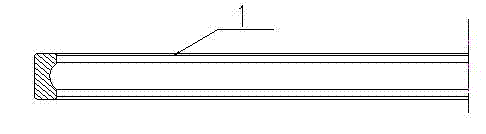

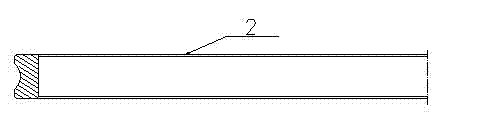

[0017] as attached figure 1 It is the finished outer ring 1 of the ultra-thin wall bearing, with figure 2 It is the finished inner ring of ultra-thin-walled bearing 2.

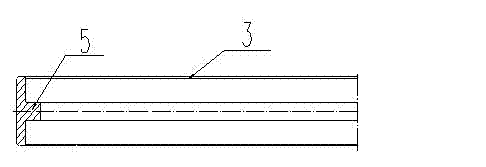

[0018] to be processed as attached figure 1 , 2 For the finished outer ring 1 and finished inner ring 2, the processing method adopted by the present invention is as follows: first, the forging blank is selected according to the size of the bearing ring to be processed, and the forging blank is turned into a car with a reinforcing ring 5 inside. Second as attached image 3 Outer ring turning workpiece shown and attached Figure 4 The shown inner ring turning workpiece; then after the turning workpiece with the reinforcement ring 5 is heat-treated, the groove is directly processed by grinding instead of turning into the attached Figure 5 Outer race shown before cutting off and as attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com