Triple-spring safety valve

A safety valve, spring-type technology, applied in the field of safety valves, can solve the problems of performance and quality that cannot meet contemporary needs, and achieve the effect of reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

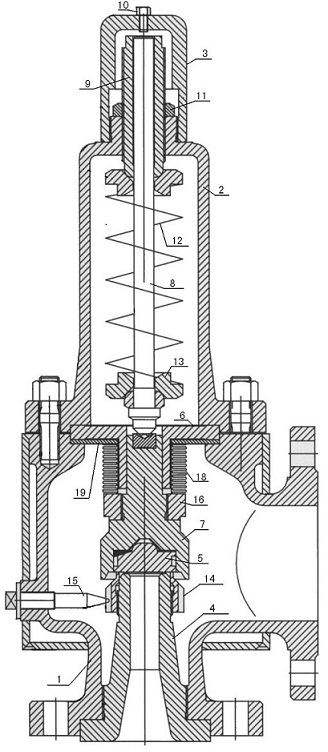

[0039] Below in conjunction with accompanying drawing and concrete example for further explanation:

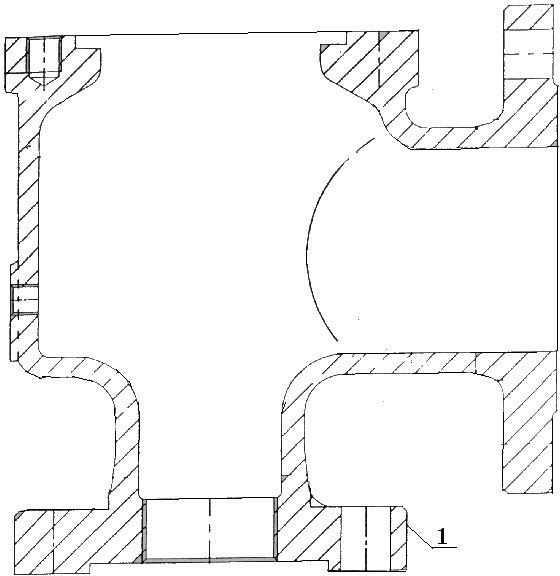

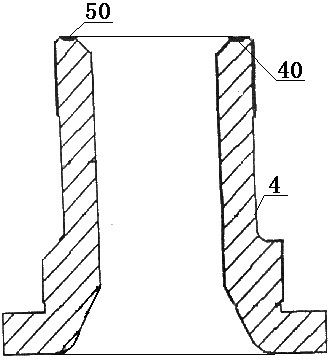

[0040] The valve body 1, valve cover 2 and bonnet 3 of the Sanhua spring safety valve of the present invention are connected sequentially from bottom to top, and the valve seat 4, valve disc 5 and outer peripheral sleeve T-shaped guide plate 6 are connected sequentially from bottom to top. Recoil disc 7, valve stem 8, adjusting screw rod 9 and screw plug 10; a lock nut 11 is also set between the top of the valve cover 2 and the adjusting screw rod 9, and the valve stem 8 is also set with a spring 12 under the adjusting screw rod 9 And the spring seat 13, the outer periphery of the upper part of the valve seat 4 is equipped with an adjusting ring 14 through a screw, and the valve body 1 is equipped with a positioning screw 15 for fixing the adjusting ring 14; A corrugated pipe 18 made of one or more layers of corrosion-resistant materials is installed between the supporting sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com