Bulb lamp production method and bulb lamp produced thereby

A bulb lamp, spherical technology, applied in the direction of lampshade, electric lamp circuit layout, lighting and heating equipment, etc., can solve problems such as the effective irradiation range and illuminance are not ideal, the light color temperature is inconsistent, and the lighting requirements cannot be met. The effect of increasing the utilization rate of light efficiency, convenient light distribution, and ingenious structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

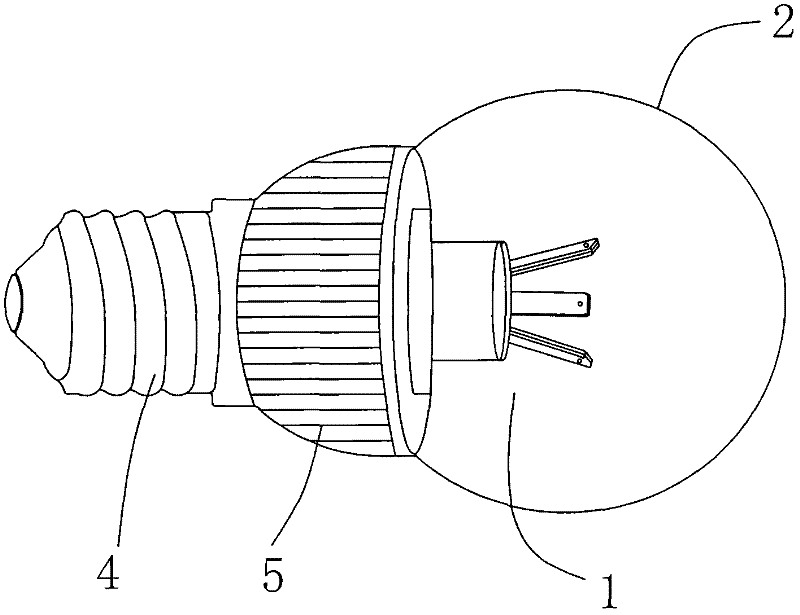

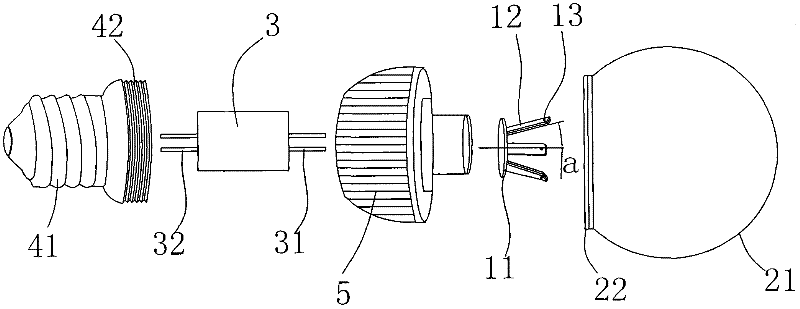

[0039] Example: see Figure 1 to Figure 3 , the embodiment of the present invention provides a kind of bulb lamp preparation method, it comprises the following steps:

[0040] (1) Prepare a multi-angle lighting module 1;

[0041] (2) Prepare a spherical glass cover 2;

[0042] (3) prepare a wide voltage adjustable driver 3, the front end of the wide voltage adjustable driver 3 is provided with an outgoing line 31, and the tail end is provided with an incoming line 32;

[0043] (4) Prepare a lamp cap 4;

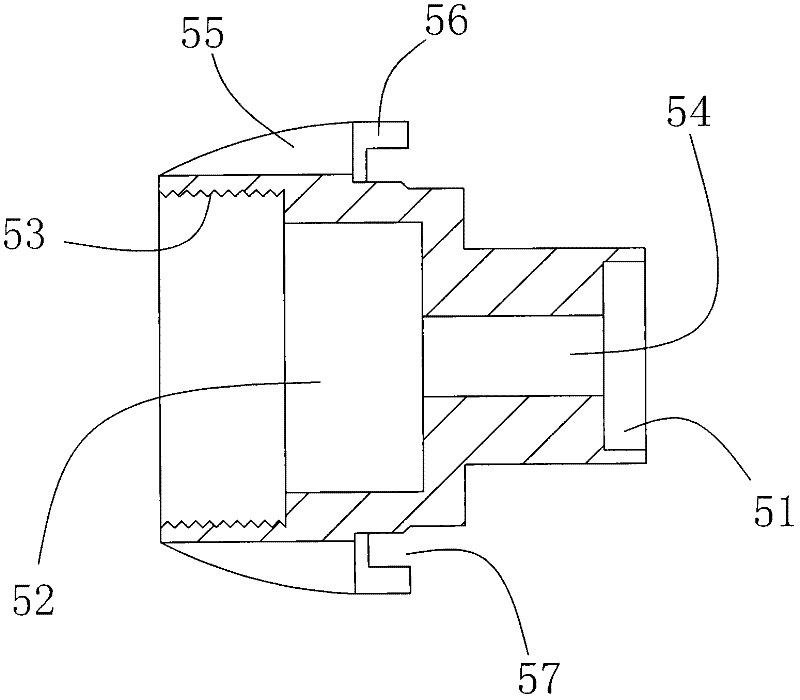

[0044] (5) Prepare a radiator 5;

[0045] (6) Fix the multi-angle light-emitting module 1 on the front end of the radiator 5, set the spherical glass cover 2 on the front part of the radiator 5, and cover the multi-angle light-emitting module 1; The wide-voltage adjustable driver 3 is inserted on the tail of the radiator 5, and the outgoing line 31 is connected to the multi-angle light-emitting module 1; the lamp holder 4 is screwed on the tail of the radiator 5, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com