Composite burning board provided with positioning grooves on double surfaces and used for roasting electronic materials

A technology of electronic materials and setter plates, applied in the field of kiln furniture, can solve problems such as abnormal shaking of kiln furniture, large volume, and influence on the stability of setter plates

Inactive Publication Date: 2012-06-27

江苏三恒高技术窑具有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Domestic kilns for producing electronic materials are mainly high-temperature kilns, which have high technical requirements on the thermal shock resistance of the setters on which the products are placed. Currently, flat setters are often used, and the setters of each layer are The square supports are laid, and the volume is large, which affects the firing effect, especially when in use, because the kiln furniture combination moves in a step-by-step manner in the kiln, and the kiln furniture combination is alternately cycled between static and moving conditions, and there will be abnormalities between the kiln furniture Shaking or slight movement, the support will shift, affecting the stability of the setter plate, and in severe cases, the setter plate will fall over, resulting in the scrapping of kiln furniture or products, affecting the normal operation of the kiln

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

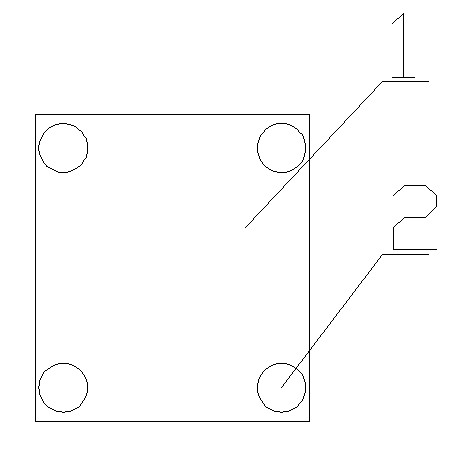

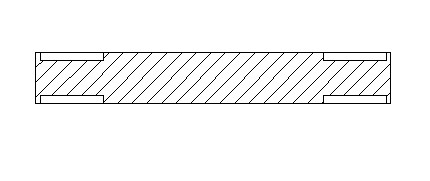

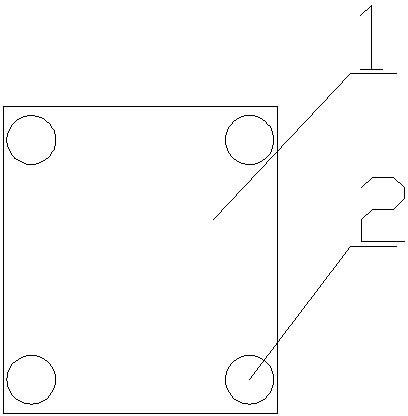

[0007] A composite setter with double-sided positioning grooves for baking electronic materials, including composite setters 1 of each layer stacked, the four corners of the rectangular body of the composite setter 1 are provided with a positioning groove 2 on the front and back of the four corners, and the upper and lower composite setters Setter plates 1 are stacked by matching the positioning grooves 2 described above with positioning pins.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A composite burning board provided with positioning grooves on double surfaces and used for roasting electronic materials belongs to the technical field of kilns and comprises various composite burning board layers which are stacked. The positioning grooves are respectively arranged on front and reverse surfaces of four corners of a rectangular body of each composite burning board layer, the upper and lower composite burning board layers are stacked by means of fittingly connecting positioning pins with the positioning grooves, a supporting effect is realized, and furthermore, when a kiln operates unstably, the burning board layers in the operation direction of the kiln and the side perpendicular direction can be positioned in a controlled manner.

Description

technical field [0001] The invention belongs to the technical field of kiln furniture, and in particular relates to a composite setter with double-sided positioning grooves for firing electronic materials. Background technique [0002] Domestic kilns for producing electronic materials are mainly high-temperature kilns, which have high technical requirements on the thermal shock resistance of the setters on which the products are placed. Currently, flat setters are often used, and the setters of each layer are The square supports are laid, and the volume is large, which affects the firing effect, especially when in use, because the kiln furniture combination moves in a step-by-step manner in the kiln, and the kiln furniture combination is alternately cycled between static and moving conditions, and there will be abnormalities between the kiln furniture Shaking or slight movement will cause the support to shift, affecting the stability of the setter plate. In severe cases, the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F27D5/00

Inventor 王立平

Owner 江苏三恒高技术窑具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com