Method and device for pre-detecting of particle impact noise detection (PIND)

A PIND, pre-detection technology, applied in measuring devices, cleaning methods and utensils, chemical instruments and methods, etc., to avoid scrap or rework and improve product quality control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

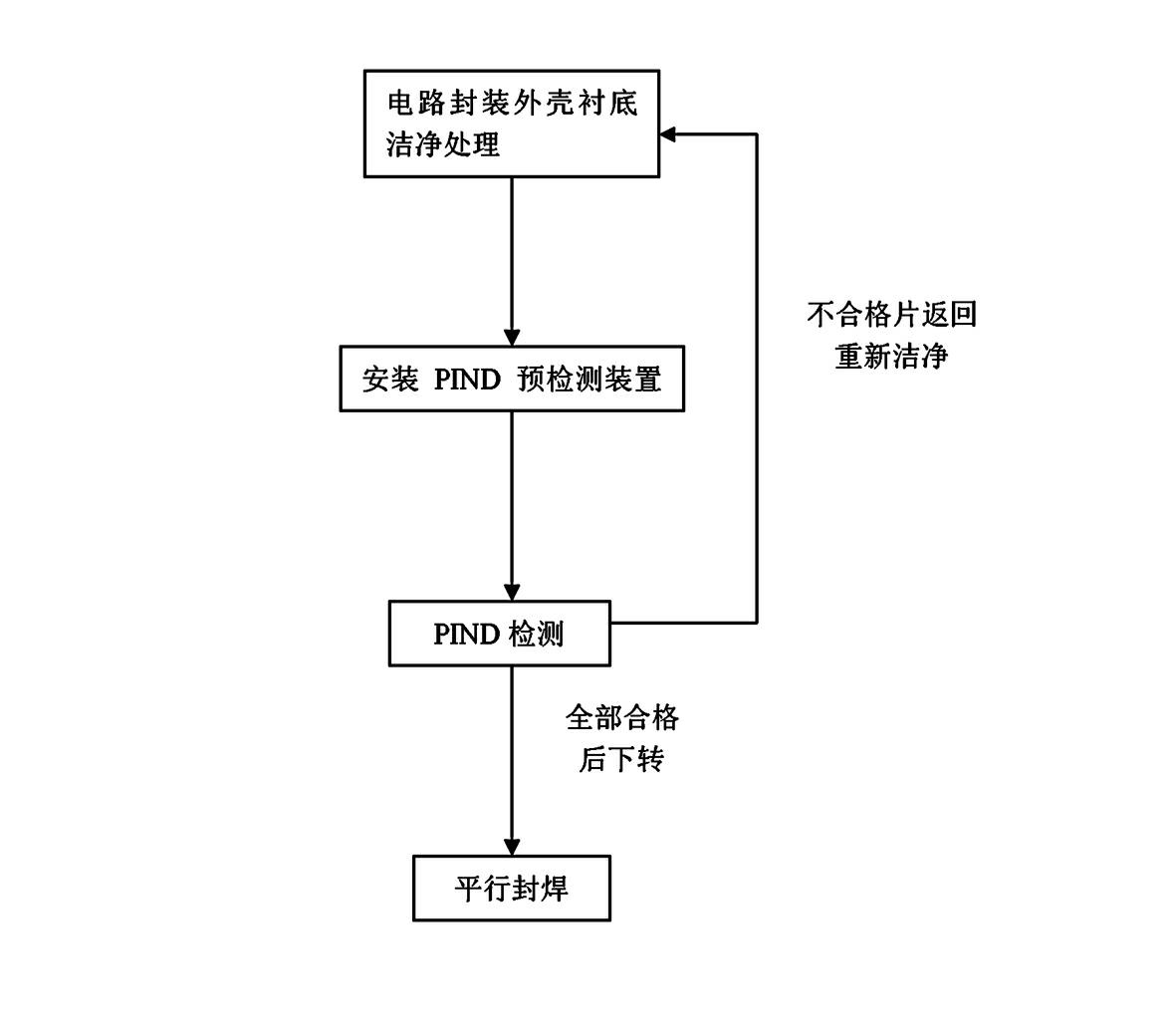

[0029] A kind of PIND pre-detection method of the present invention mainly comprises the following several parts:

[0030] process flow

[0031] Such as figure 1 As shown, the substrate of the circuit packaging shell is cleaned → installed PIND pre-inspection device → PIND inspection → unqualified inspection is cleaned again → PIND re-examination is all qualified before parallel sealing and welding;

[0032] Specific steps are as follows:

[0033] 1 Cleaning treatment of circuit packaging shell substrate;

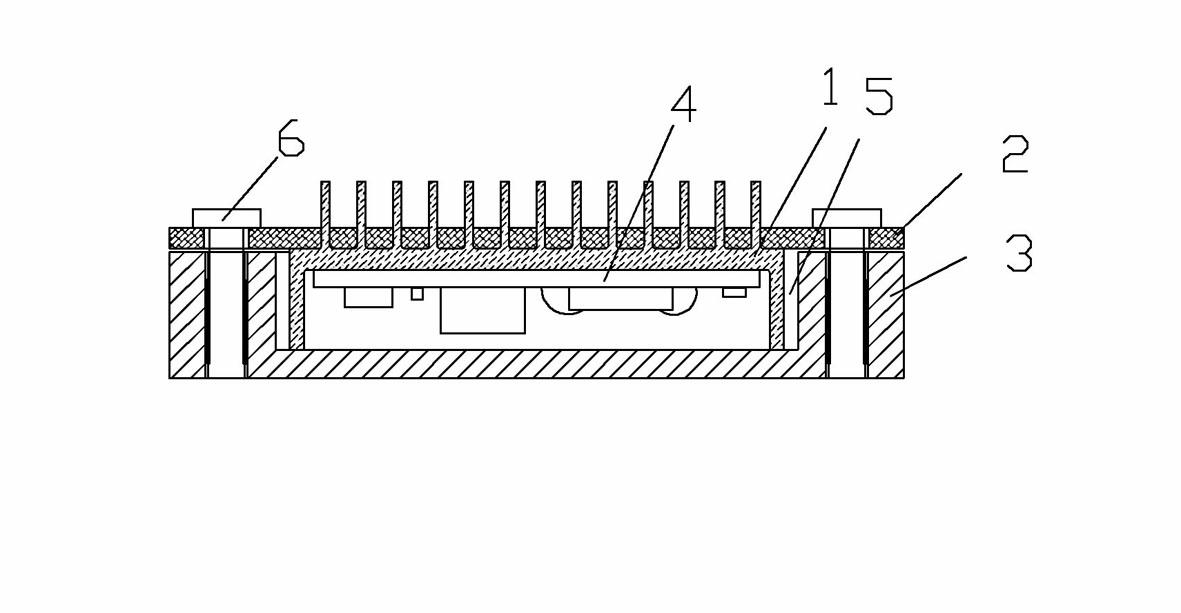

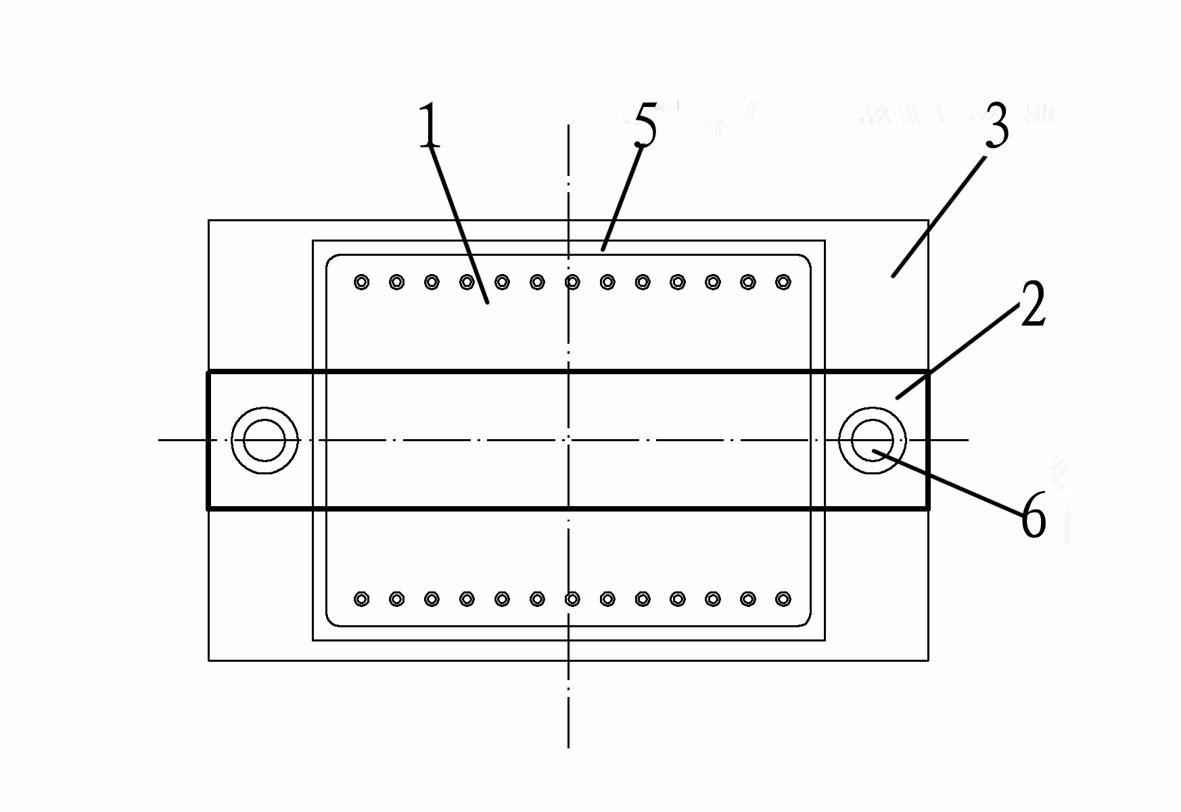

[0034] 2. Install PIND pre-detection device;

[0035] 3. PIND detection;

[0036] 4. If the test is unqualified, it will be cleaned again;

[0037] 5. Parallel sealing and welding will be carried out after all the PIND retests are qualified.

[0038] Step 1 The steps of cleaning the substrate of the circuit packaging shell are:

[0039] 1.1 Ultrasonic cleaning of the substrate: put a clean beaker containing absolute ethanol or other special cleaning containers (the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com