Storage battery pole piece coating and laminating process

A battery and pole piece technology, which is applied in the field of battery pole piece coating lamination technology, can solve the problems of unfavorable workers' health, difficult quality control, and high labor intensity, so as to improve product quality control level, reduce labor dependence, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

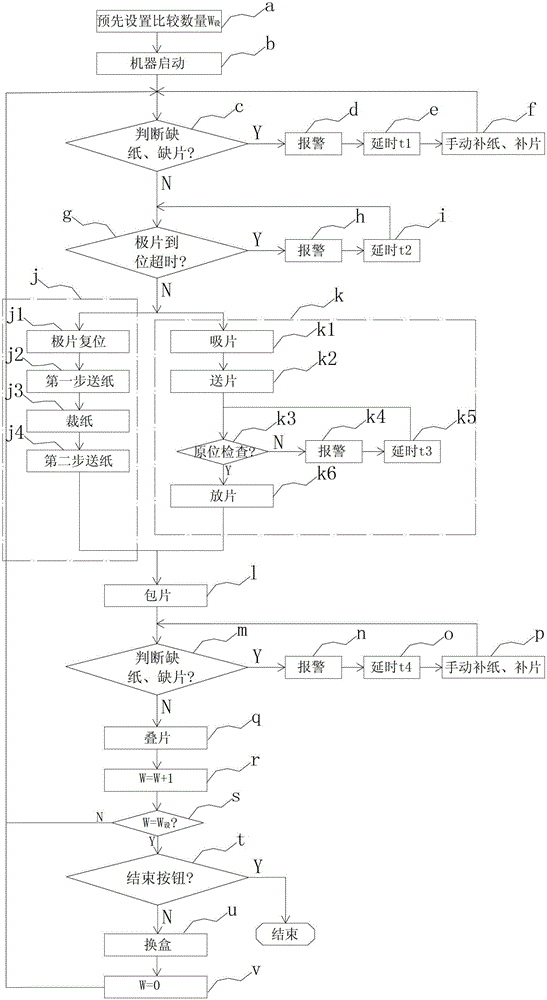

[0093] Embodiment: The wrapping area is composed of a paper loading and feeding mechanism, a feeding mechanism, a wrapping mechanism, and a stacking mechanism. The paper loading and feeding mechanism completes the functions of loading the partition paper, stepping paper feeding, and cutting paper during work; the feeding mechanism Complete the feeding of the polar plate in the work; the wrapping mechanism completes the packaging of the polar plate and the separator paper in the work; the lamination mechanism and the movement of the chain plate complete the assembly process of the polar plate from the component to the pole group; the sorting area is mainly composed of Composed of sorting mechanism and boxing mechanism; the main manipulator of the sorting mechanism completes the sorting of the shape of the pole group to meet the requirements of the process regulations; the boxing mechanism automatically completes the packing of the pole group into the tooling box, and all the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com