Temperature control circulation etching processing device for circuit boards

A technology for etching processing and circulating circuits, which is applied in educational appliances, instruments, teaching models, etc., to achieve the effects of low processing cost, easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will be described in conjunction with the accompanying drawings.

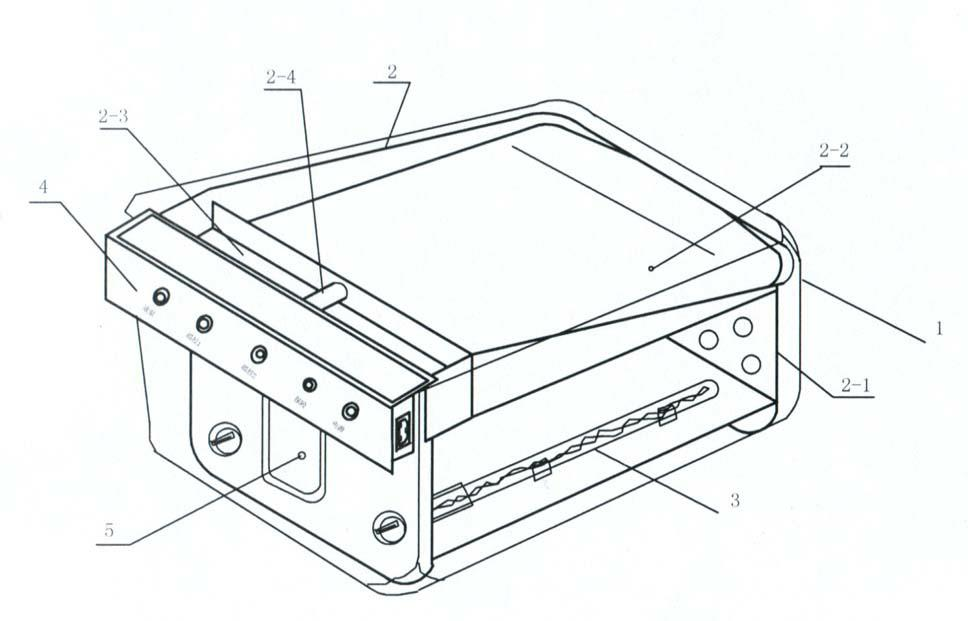

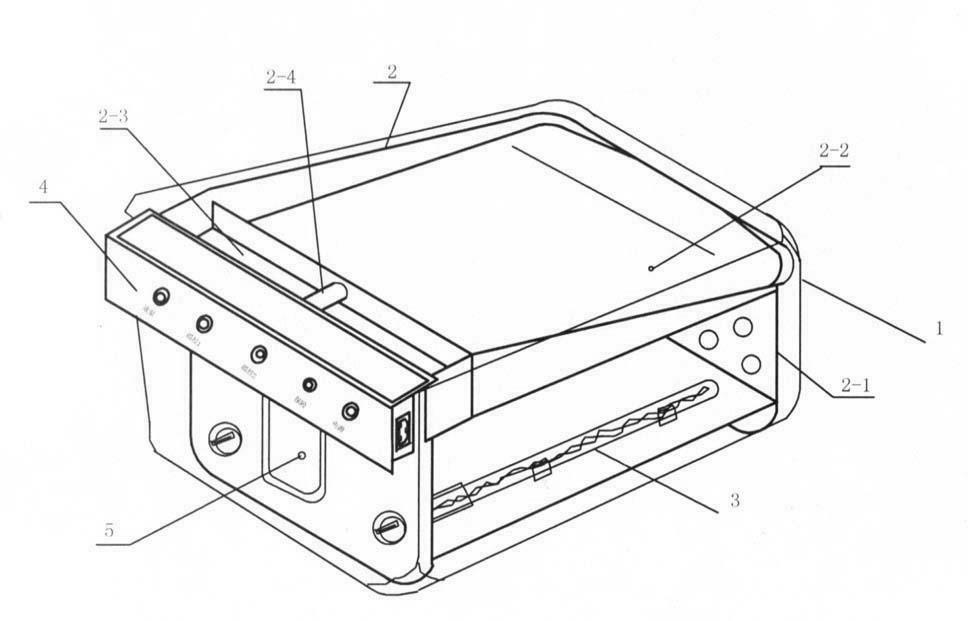

[0014] figure 1 As shown, the temperature control cycle circuit board etching processing device of the present invention. It includes a box body 1, an etching working part 2, a liquid circulation system, a heating control device 3, and an electrical control part 4; the etching working part is installed in the box body;

[0015] l The box is a corrosion-resistant plastic box with an upper opening.

[0016] l The etching working part 2 includes a base 2-1 and a liquid flow slope part 2-2. The base is formed by welding the bottom plate and the front and rear side plates, wherein: the front and rear side plates are provided with several holes for liquid and wire through holes, and a pump box is arranged at the bottom plate and the front side plate; the liquid flow slope part is welded on the base; Liquid tank 2-3. In order to prevent liquid from spraying out during pumping, an inverted V-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com