Charging and discharging device for aluminum electrolytic capacitor

A technology for aluminum electrolytic capacitors and racks, which is applied in capacitors, capacitor manufacturing, circuits, etc., and can solve problems such as abnormal feeding, economic losses, and equipment failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

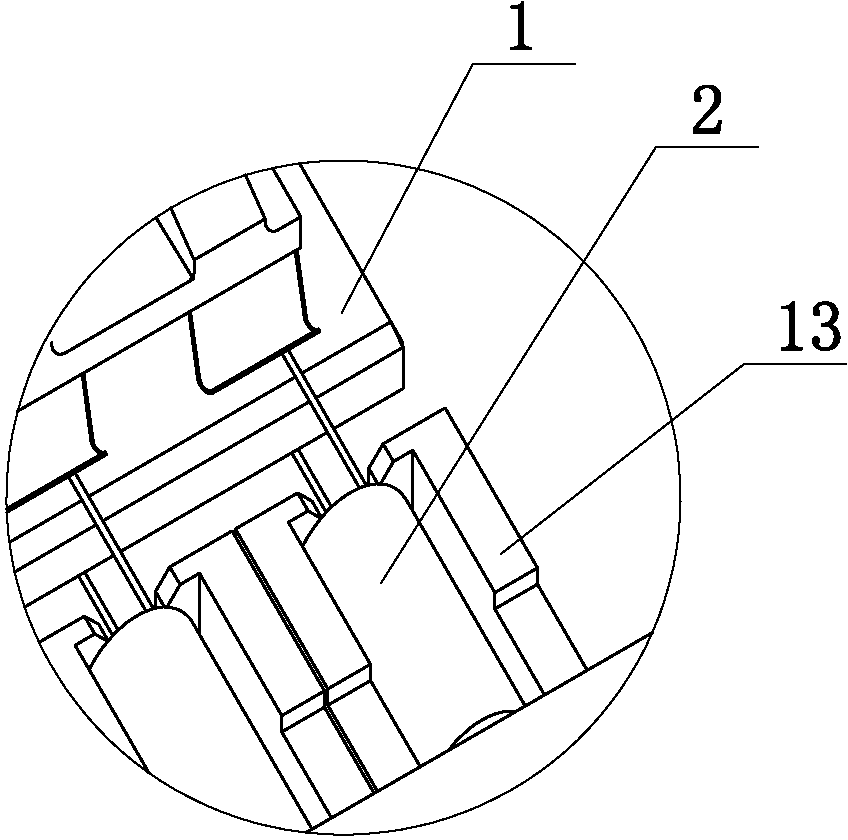

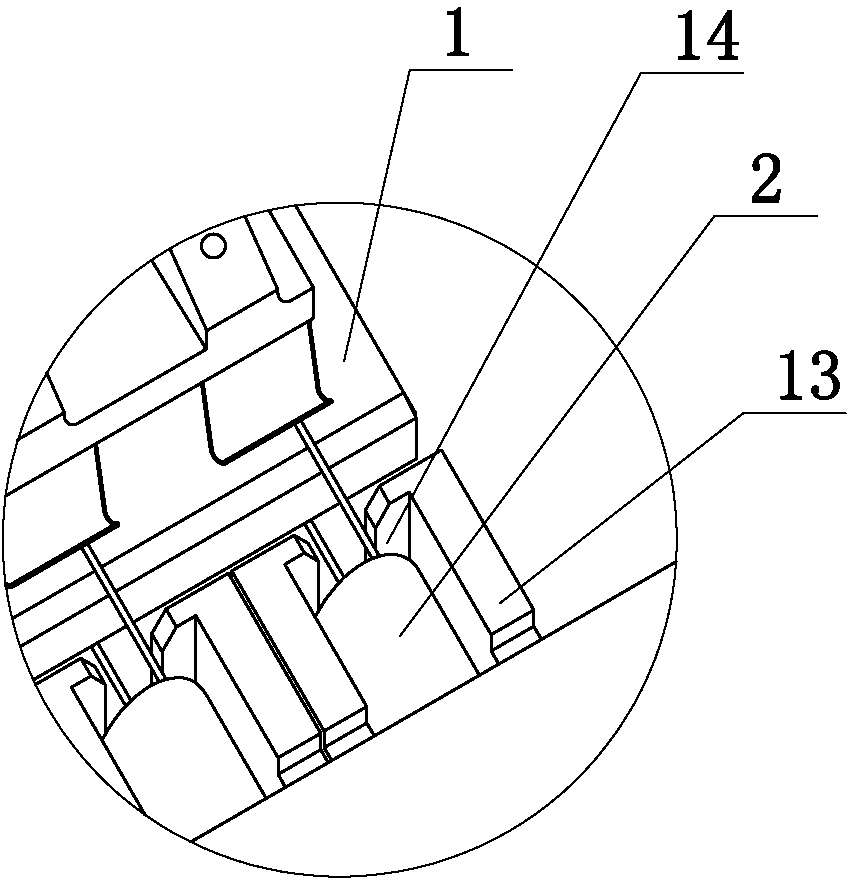

[0015] Depend on figure 1 It can be seen that when the aluminum electrolytic capacitor 2 is handed over between the delivery bracket 13 and the aging fixture 1, since there is no gap between the end of the rubber plug of the product (especially the product with a rubber plug and a step) and the inside of the front end of the delivery bracket 13, the upper , during blanking, the product and the inner front end of the delivery support 13 produce friction, which affects the normal loading and unloading of the product.

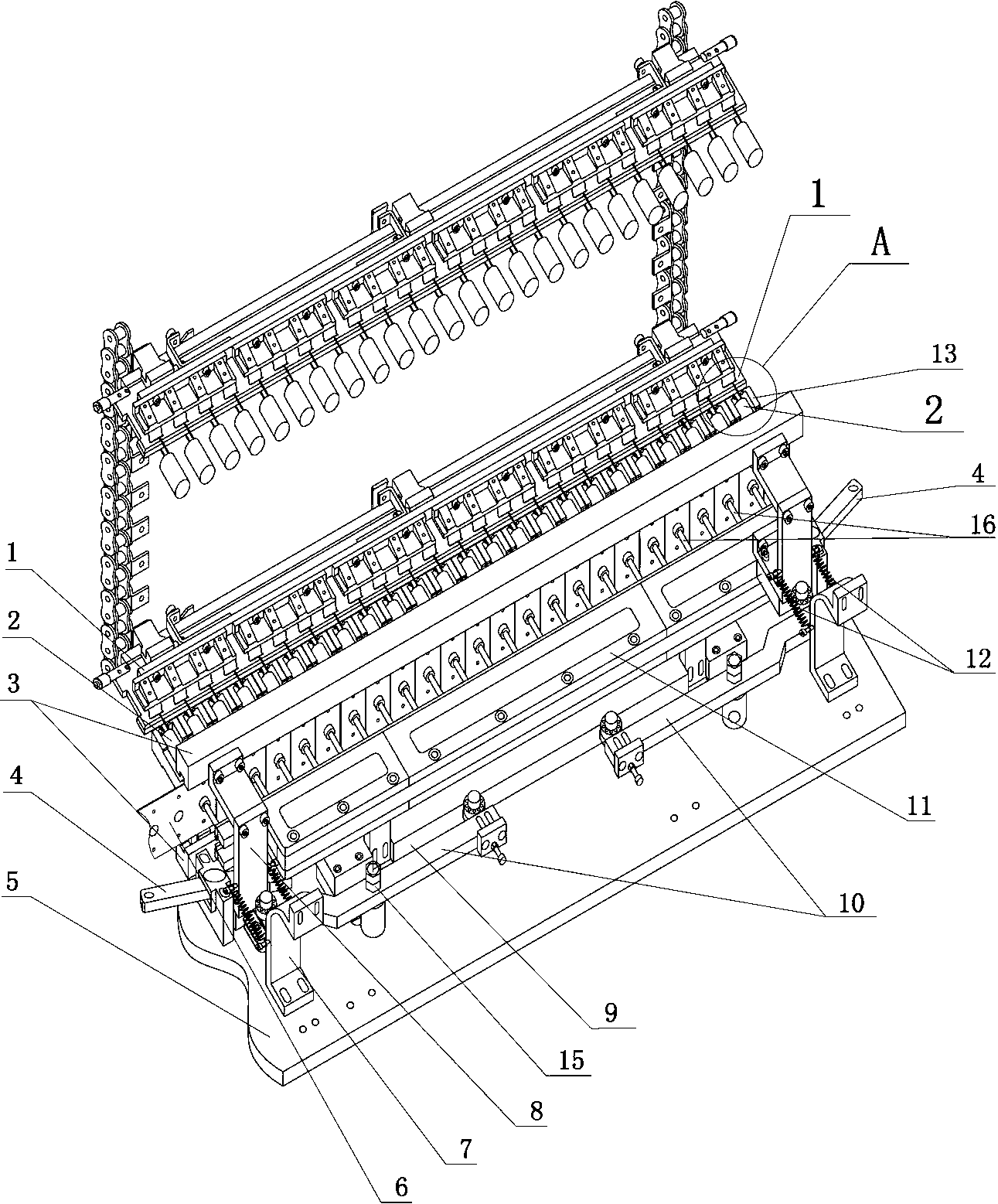

[0016] Depend on figure 2 , image 3 It can be seen that a loading and unloading device for aluminum electrolytic capacitors includes a frame 5, and an annular stepping device controlled by a control device is arranged on the frame 5. 3 step-by-step annular stepping conveyor belt 6, the endless stepping conveyor belt 6 is provided with a delivery bracket 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com