Grass pressing roller device for grass cutter

A grass cutter and grass pressing technology, which is applied in cutting equipment, agricultural machinery and implements, applications, etc., can solve problems such as affecting processing and difficult feeding of feed into the pulverizer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

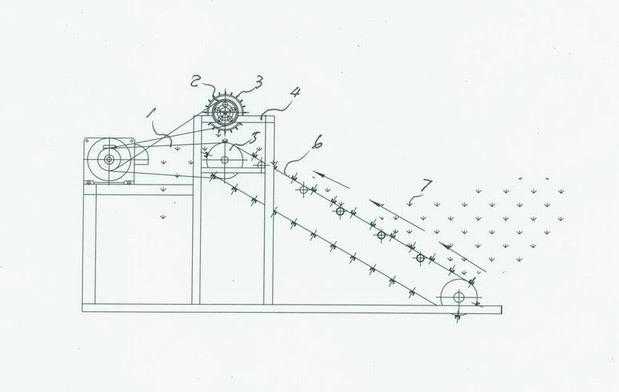

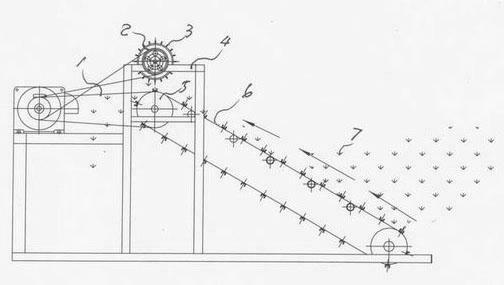

[0005] The present invention is described in detail in conjunction with above-mentioned accompanying drawing, feed chopper of the present invention comprises frame, feeding device and shredder, and wherein feeding device is made up of inclined conveyer belt 6 and horizontal conveyer belt 1, and the left end of horizontal conveyer belt and The feeding port of the shredder is connected, the right end of the horizontal conveyor belt is opposite to the upper end of the inclined conveyor belt, and the grass pressing roller 2 is arranged on the frame 4, which is opposite to the main drive roller 5 at the upper end of the inclined conveyor belt below, and the grass is pressed The roller sleeve is placed in the vertical long hole on the frame beam. The external thread on the outer surface of the sleeve is matched with a nut. The height of the grass-pressing roller realizes the thickness of grass-pressing, and grass-pulling claws 3 are distributed on the peripheral surface of the grass-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com