Method for applying natural solid flavors and fragrances to papermaking-reconstructed tobacco sheets

A technology for flavors, fragrances, and tobacco sheets, which is applied to tobacco, tobacco preparation, and tobacco processing, can solve problems such as large irritation of sheets, and achieve the effects of improving internal quality, reducing irritation and tar content, and making the smoke soft and delicate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

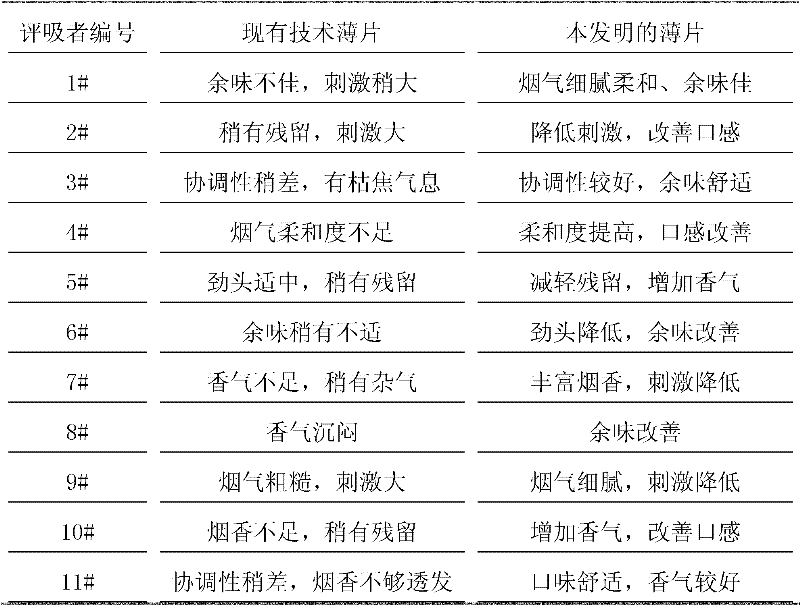

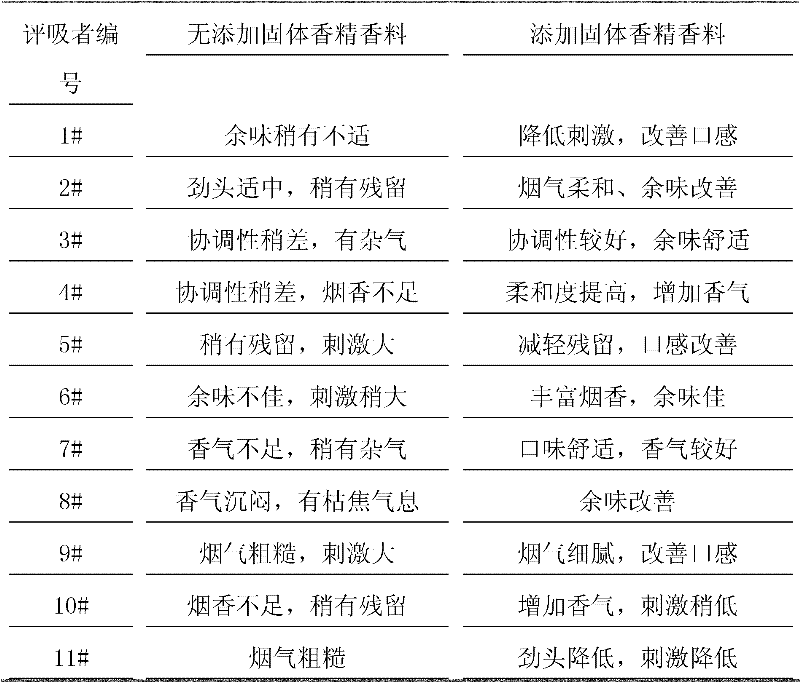

Examples

Embodiment 1

[0054] [1] Preparation of natural solid flavor and fragrance

[0055] All 9 kinds of raw materials are selected according to the following weight percentages: 25% fenugreek, 8% red dates, 12% Luo Han Guo, 10% licorice, 9% peanut shells, 16% stevia, 8% coffee, 10% iris, 2% white pepper .

[0056]Take 15kg of fenugreek, 4.8kg of red dates, 7.2kg of Luo Han Guo, 6kg of licorice, 5.4kg of peanut shells, 9.6kg of stevia, 4.8kg of coffee, 6kg of iris, and 1.2kg of white pepper according to the above formula, a total of 60kg. After mixing the materials evenly, place them in an oven to dry at 110°C for 10 hours, and let them cool naturally overnight. The dried mixture is crushed to 180 mesh to obtain natural solid flavors and fragrances for later use.

[0057] [2] In the production process of paper-making flakes, in the canning process, the above-mentioned natural solid flavors and fragrances are added to the paper-making flakes to obtain tobacco flakes containing natural solid flavo...

Embodiment 2

[0069] [1] Preparation of natural solid flavor and fragrance

[0070] Six kinds of raw materials are selected and formulated according to the following weight percentages: 20% fenugreek, 32% red dates, 8% monk fruit, 15% licorice, 9% stevia and 16% iris.

[0071] Take 20kg of fenugreek, 32kg of red dates, 8kg of Luo Han Guo, 15kg of licorice, 9kg of stevia, and 16kg of iris according to the above formula, totaling 100kg. After the materials are evenly mixed, place them in an oven and dry them at 110°C for 10 hours, and let them cool naturally overnight. The dried mixtures are crushed to 180 mesh to obtain natural solid flavors and fragrances, which are ready for use.

[0072] [2] In the production process of paper-making flakes, the above-mentioned natural solid flavors and fragrances are added to the concentrated solution, and then coated on the film base to obtain tobacco flakes containing natural solid flavors and fragrances. The specific operations are as follows:

[0073...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com