Device for producing and method for producing wet wipes

A manufacturing method and a manufacturing device technology, which are applied in the field of wet wipes manufacturing and manufacturing devices, can solve problems such as deviation, low liquid penetration rate, and inability to manufacture products with the desired amount of prescribed drugs, so as to prevent deviation and prevent Effect of decline in ease of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

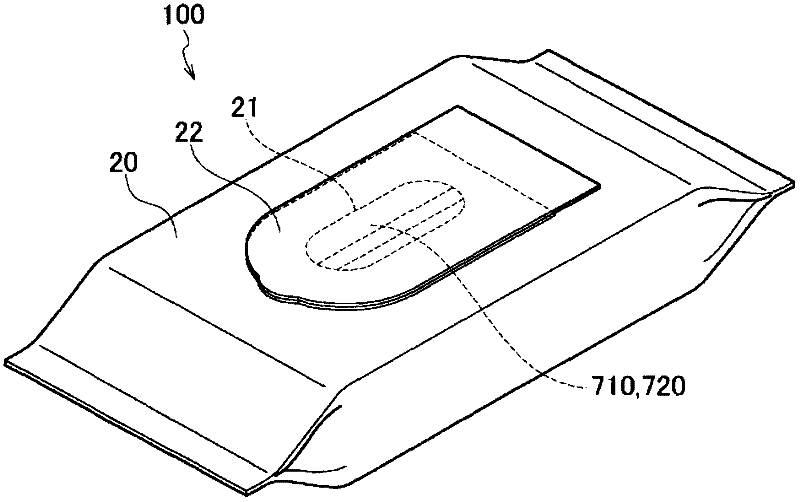

[0023] refer to Figure 1 ~ Figure 3 The wet tissue manufactured by the manufacturing apparatus 10 which concerns on 1st Embodiment of this invention is demonstrated. This wet tissue is composed of a laminate of wet tissue sheets 710 and 720 impregnated with a predetermined chemical solution.

[0024] Such as figure 1 As shown, the package 100 of the wet wipes includes: a package body 20, which has an opening 21; a label (label) member 22, which is installed on the outer surface of the package body 20, for covering the opening 21; The laminated body of the napkin sheets 710 and 720 is housed inside the package main body 20 .

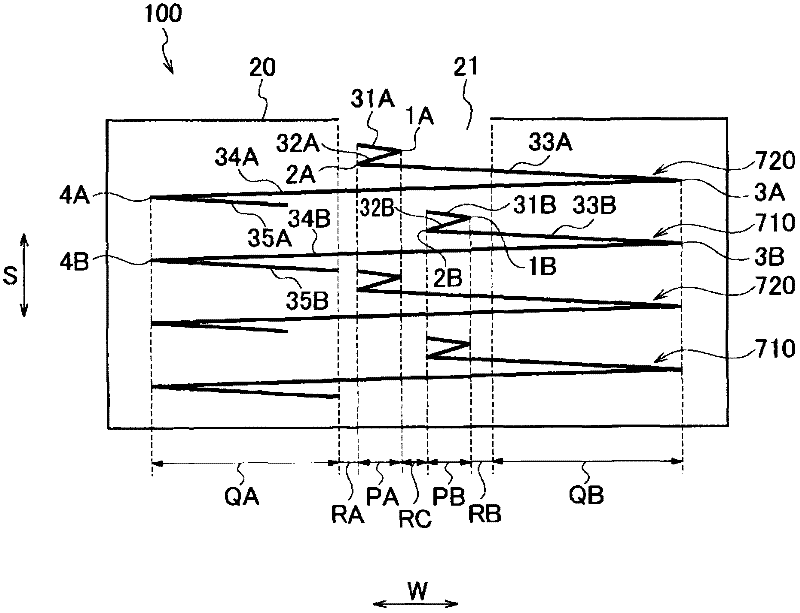

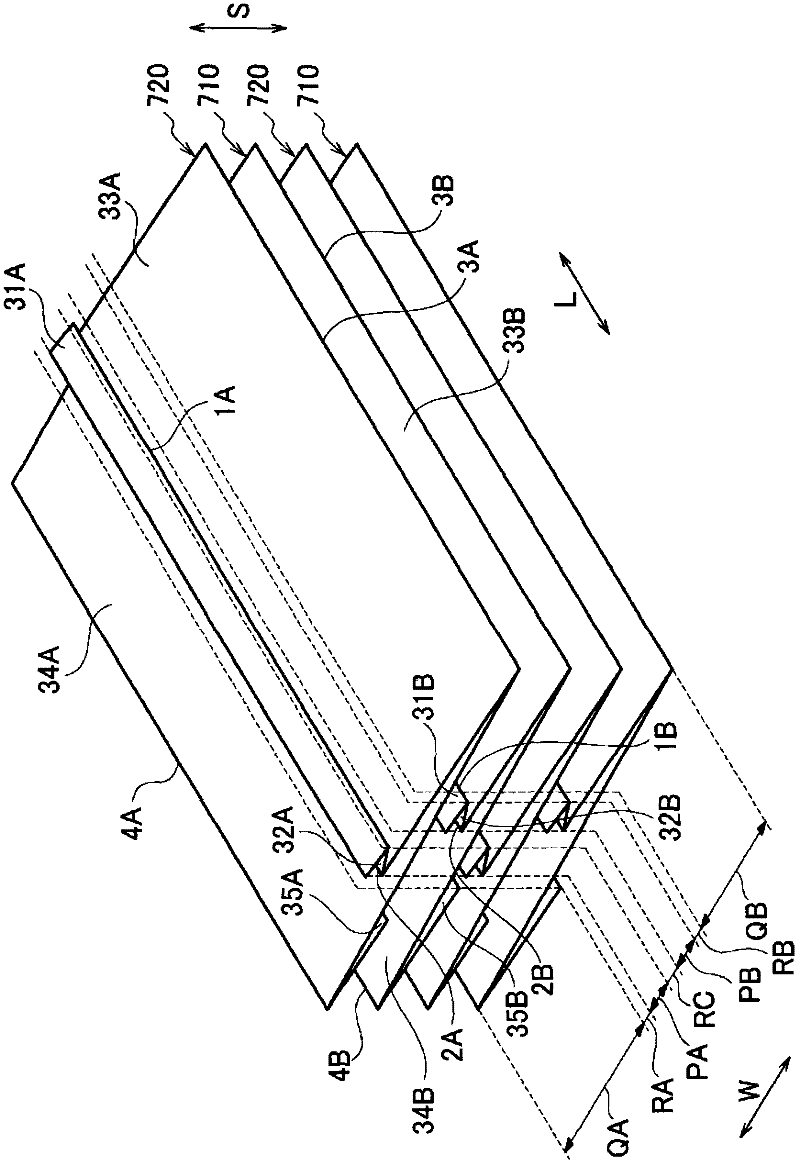

[0025] Such as figure 2 and image 3 As shown, the wet tissue sheets 710 and 720 are both stored inside the package main body 20 in a folded state.

[0026] Such as figure 2 and image 3 As shown, sheet 720 includes regions 31A, 32A, 33A, 34A, and 35A, and sheet 710 includes regions 31B, 32B, 33B, 34B, and 35B.

[0027] Here, on the wet tissue ...

Embodiment

[0089] A laminated body consisting of 72 wet tissue sheets was packaged in the package main body, and a take-out test was performed in which the wet tissue sheets were taken out one by one. The result is as Figure 7 (a) ~ (c) shown. In detail, a production line is constructed in which four wet tissue sheets are laminated to form one set. That is, a laminated body consisting of 18 sets was produced and enclosed in a package.

[0090] Figure 7 (a) shows the result of the take-out test of the laminated body without performing the pressing process, Figure 7 (b) shows the result of taking out the laminated body that pressed the entire surface, Figure 7 (c) shows the result of the take-out test of the laminated body which performed the pressing process by the pressing apparatus of embodiment. Figure 7 The vertical axes of (a) to (c) represent the amount by which the next wet tissue sheet is pulled out when ejection of the wet tissue sheet (a phenomenon in which the next we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com