High-flow pressure-compensated drip irrigation emitter

A pressure compensation and irrigation technology, applied in the direction of spray device, spray device, etc., can solve the problems of large water demand and large terrain slope, and achieve the effect of large water demand, good pressure compensation performance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

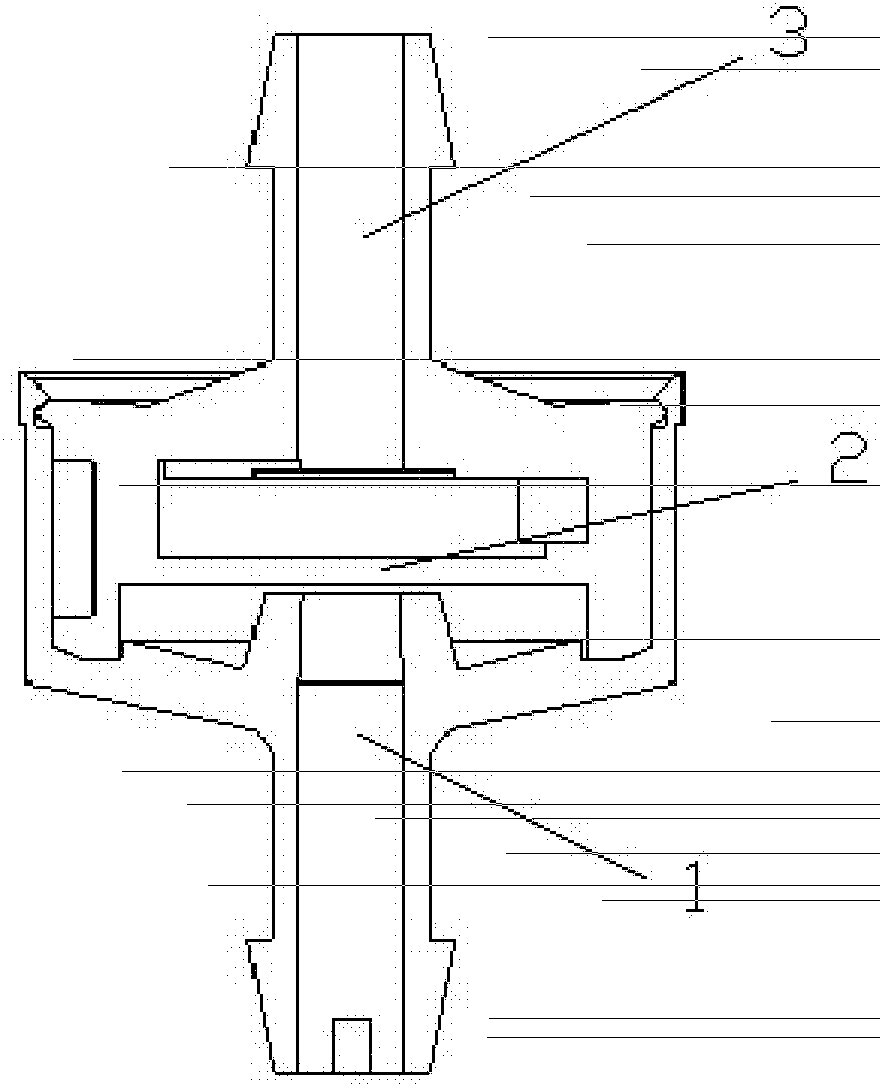

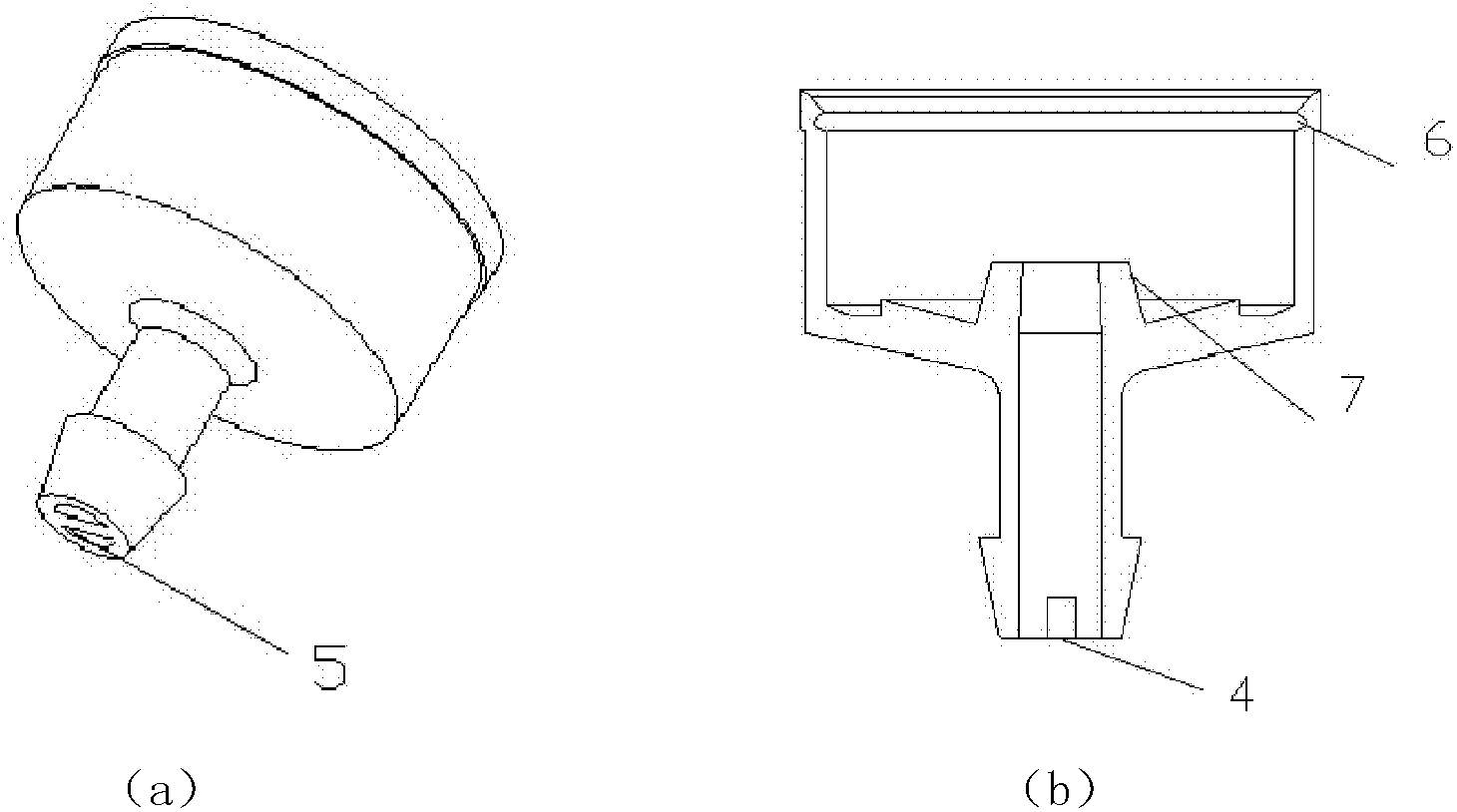

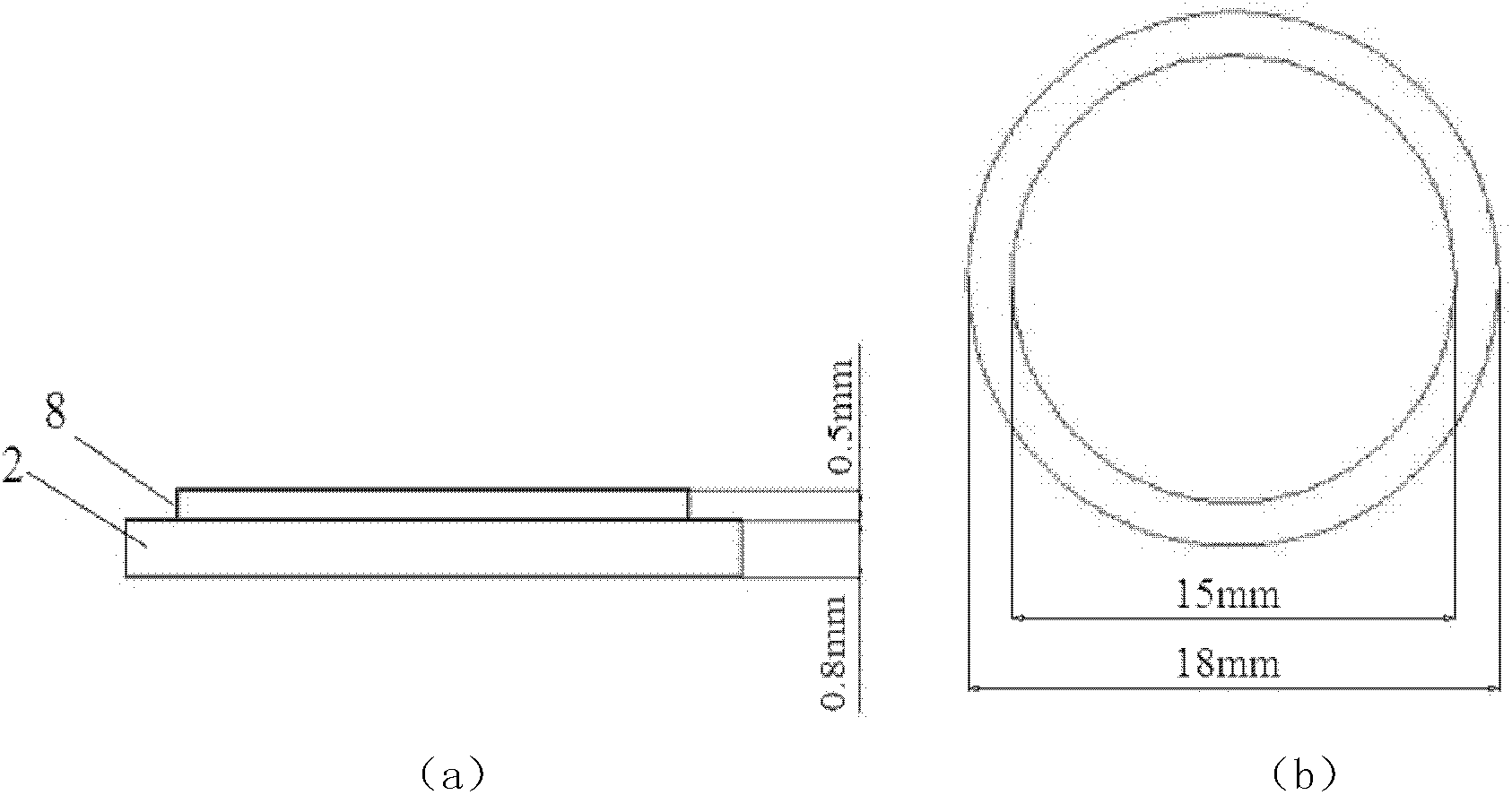

[0022] see figure 1 , the present embodiment provides a large-flow pressure-compensated drip irrigation emitter. The buried pressure-compensated spring root irrigation emitter is a combined structure, including a cavity 1, a pressure compensation gasket 2 and a base 3, and the three are cavity 1, pressure compensation gasket 2, and base 3 according to the order of water discharge. Seat 3. The cavity 1 is closely combined with the base 3 through the slot. The pressure compensating gasket 2 is located on the internal step structure of the base 3 . Matching with the step structure inside the base 3 ensures that the pressure compensating gasket 2 is fixed between the cavity 1 and the base 3 . The upper part of the pressure compensation gasket is the water inlet of the cavity 1, and the lower part is the water outlet of the base 3. When the upper part of the pressure compensation gasket 2 is under pressure, it is sunken, so that the emitter has different water outlet areas under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com