Press fitting fixture for engine crankshaft sprocket

A technology of crankshaft sprocket and engine, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of high labor intensity of the operator, affecting the precision of workpiece pressing, affecting the production progress, etc., to avoid frequent disassembly, improve Assembly efficiency, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

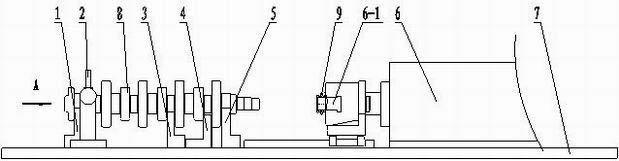

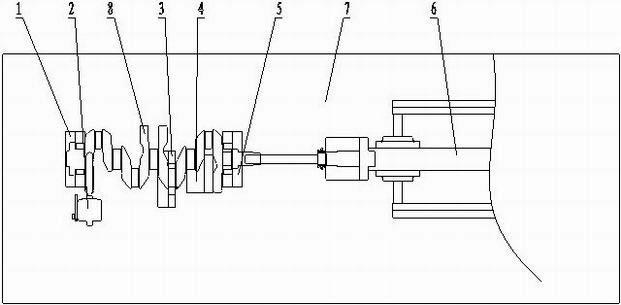

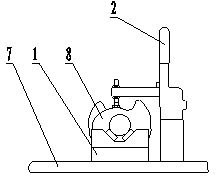

[0020] See Figure 1, figure 2 , Figure 5 , the present invention is a universal sprocket press-fitting fixture for two kinds of crankshaft workpieces whose crankshaft crank radiuses are R1 and R2 respectively, and its composition includes an angle limit support 3, a limit block 4, a V-shaped support, a clamping device 2 and Base plate 7, said base plate 7 is arranged horizontally, said angle limit support 3, limit block 4, V-shaped support, and clamping device 2 are all fixed on the base plate 7, and said angle limit support 3 is used to limit crankshaft 8 It is installed under the second connecting rod journal 8-2 of the crankshaft, and it is arranged obliquely with the matching surface of the second connecting rod journal of the crankshaft. The included angle between the matching surface and the base plate 7 is β.

[0021] see figure 1 , figure 2 , the limiting block 4 in the present invention is provided with a base and a vertical wall, and the base is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com