Clamp splice composite set specially used for centre-hole-free shaft section knurling process

A combined device and center hole technology, which is applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of lack of center hole positioning and difficult processing, etc., and achieve good positioning effect, good processing requirements, and strong overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

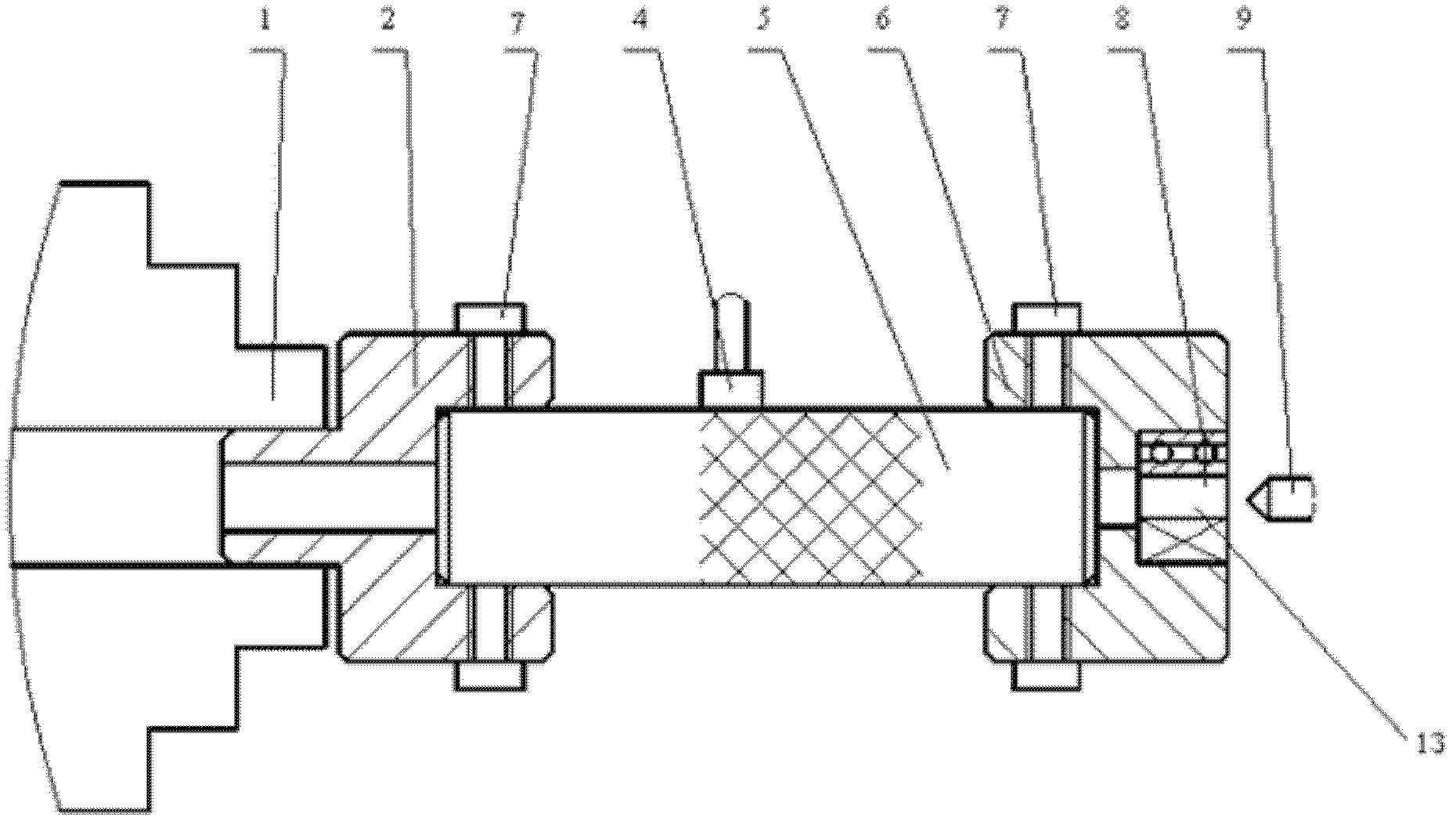

[0022] see Figure 1 to Figure 5 As shown, the present invention is a clamp block combination device specially used in the knurling process of the shaft section without a center hole. The screw 7, the clamping block at the spindle end of the lathe and the tailstock end clamping block of the lathe are made of 45 steel materials.

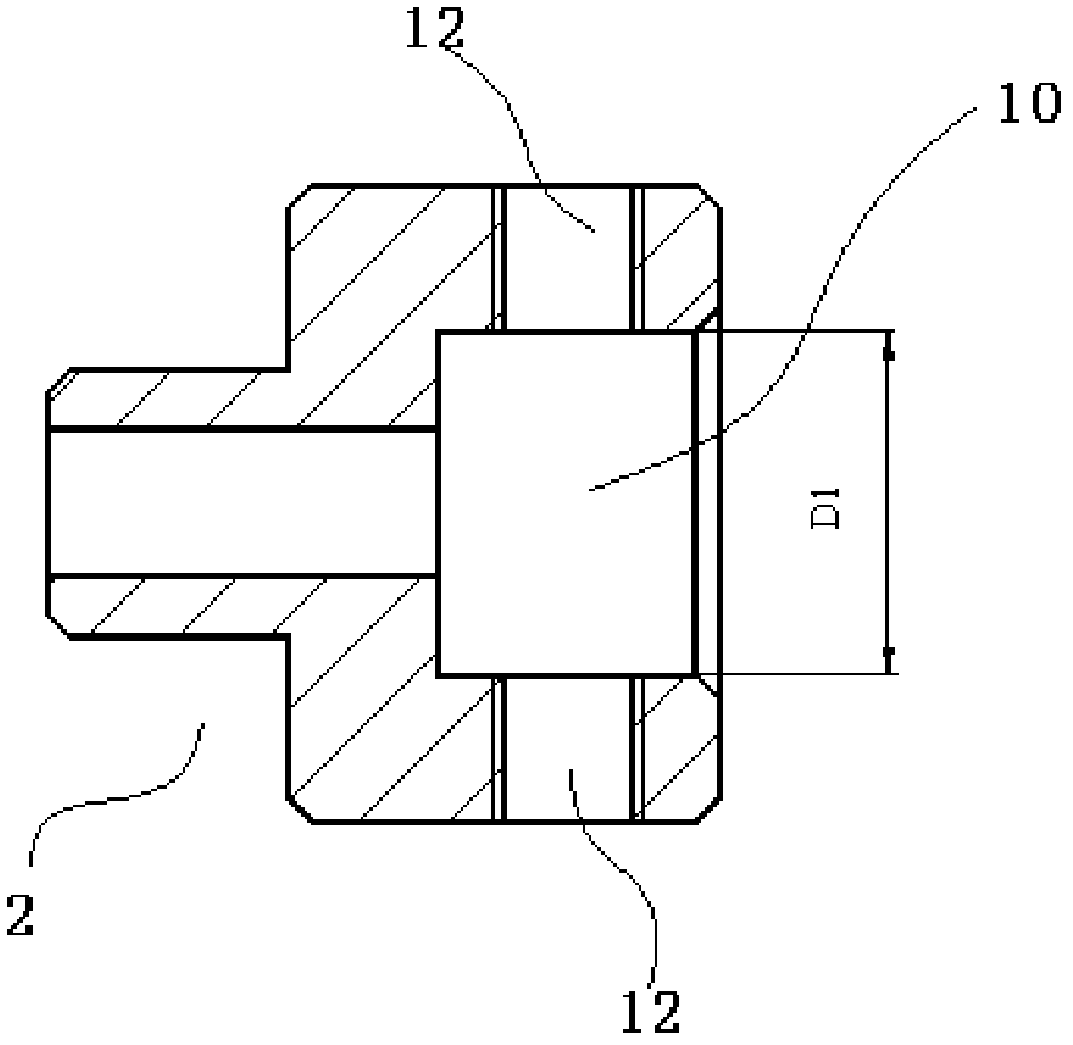

[0023] The cross-section of the lathe spindle end clamping block 2 of the utility model is "convex" shape, and one end of the lathe spindle end clamping block 2 is provided with a first placement groove 10, and the lathe spindle end clamping block 2 is symmetrically provided with 4 The bottom of each hole terminates in the internally threaded through hole 12 in the first placement groove 10 .

[0024] One end of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com