Power tool

A power tool and drive shaft technology, applied in the field of power tools, can solve problems such as large sudden change of torque and impact, and achieve the effects of simple and compact structure, convenient use, labor saving and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

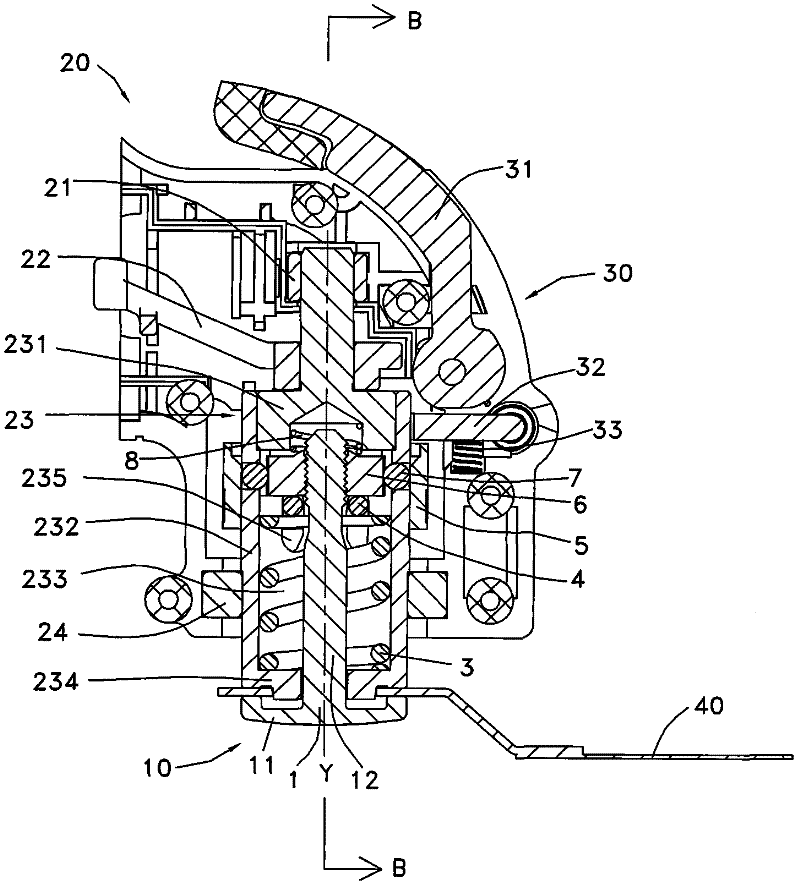

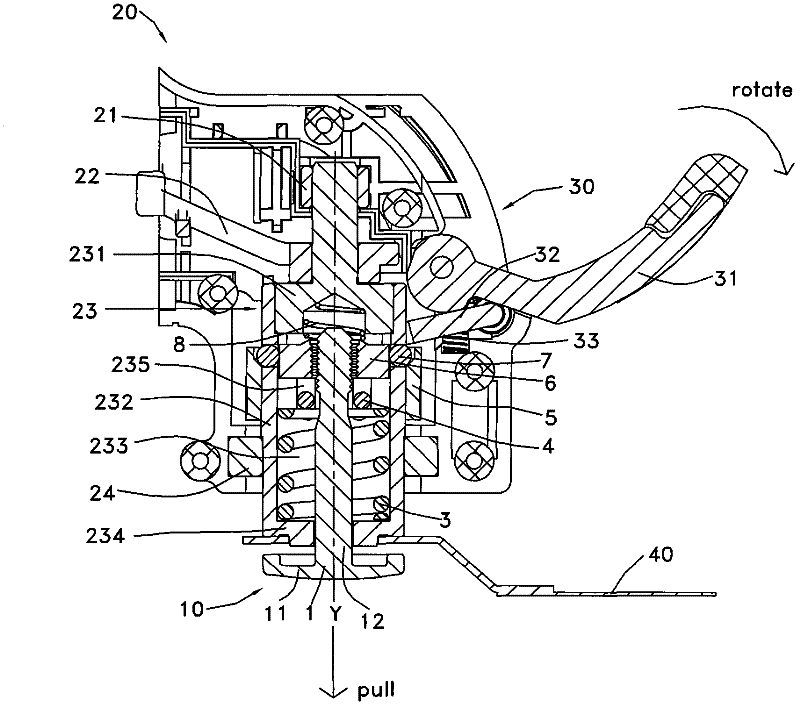

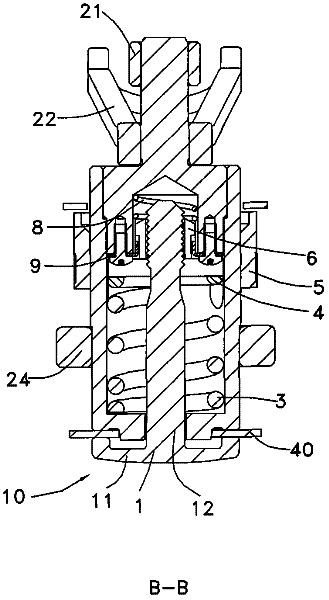

[0032] Such as Figure 1 to Figure 4 As shown, the present invention is preferably described as a power tool 20 that drives the working element 40 in an oscillating manner. The power drive shaft 23 of the power tool 20 is supported by bearings 21, 24 and rotates around its axis Y under the action of the vibrating support 22. Small yaw angle and high-frequency reciprocating swing, the drive shaft 23 is configured to support the journal 231 and the hollow shaft 232, the vibration support 22 is interference-fitted on the support journal 231, and the support journal 231 and the hollow shaft 232 interference press fit, support journal 231 and hollow mandrel 232 are surrounded by cavity 233, the shaft end 234 of driving shaft 23 is provided with the protrusion that prevents working element 40 from rotating, is connected on the driving shaft 23 and is used for working element 40 The clamping device 10 is quickly clamped to the shaft end 234 .

[0033] The clamping device 10 comprise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com