A square wood product wrapping machine

A technology for wood products and cladding machines, which is used in wood processing appliances, household components, etc., can solve the problems of unusable, easy to warp, unsightly, etc., and achieves the effect of not easy to warp, not afraid of moisture, and beautiful in appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

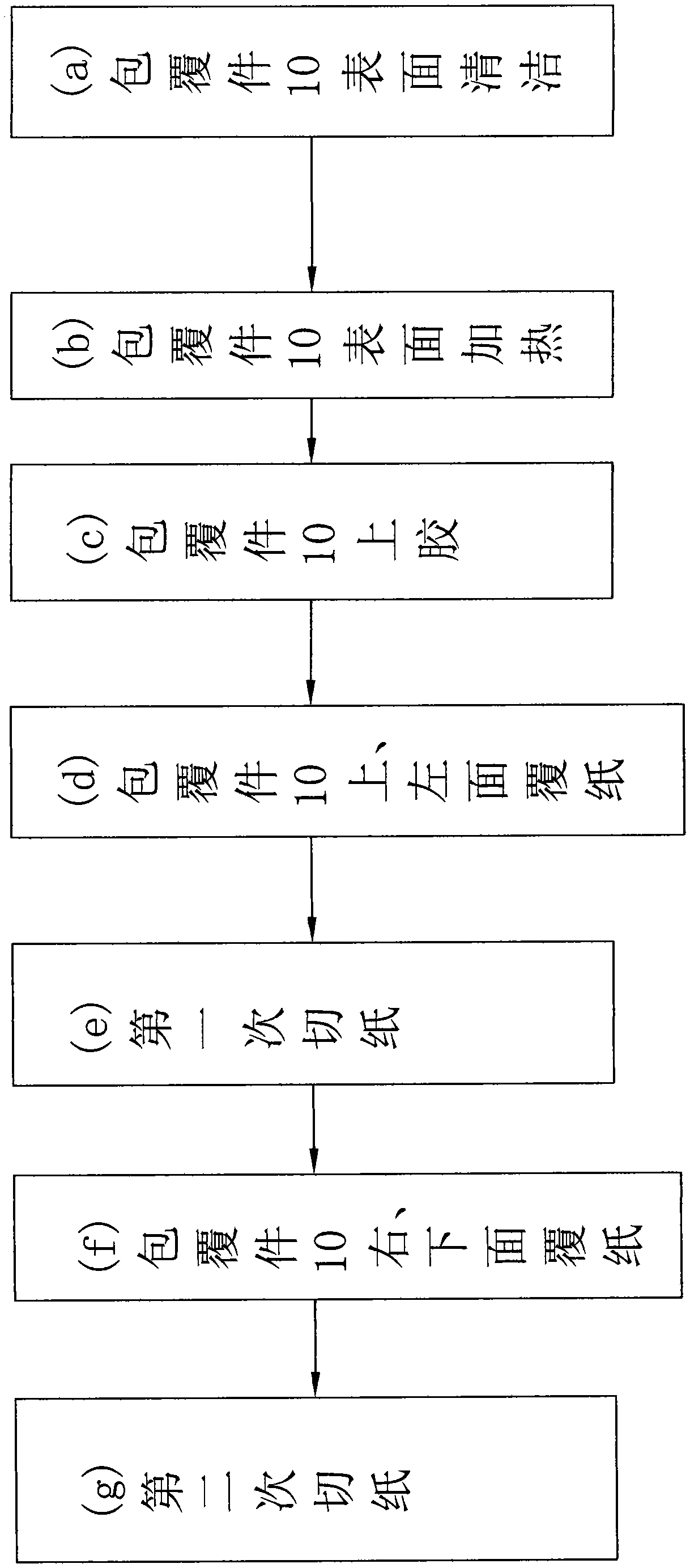

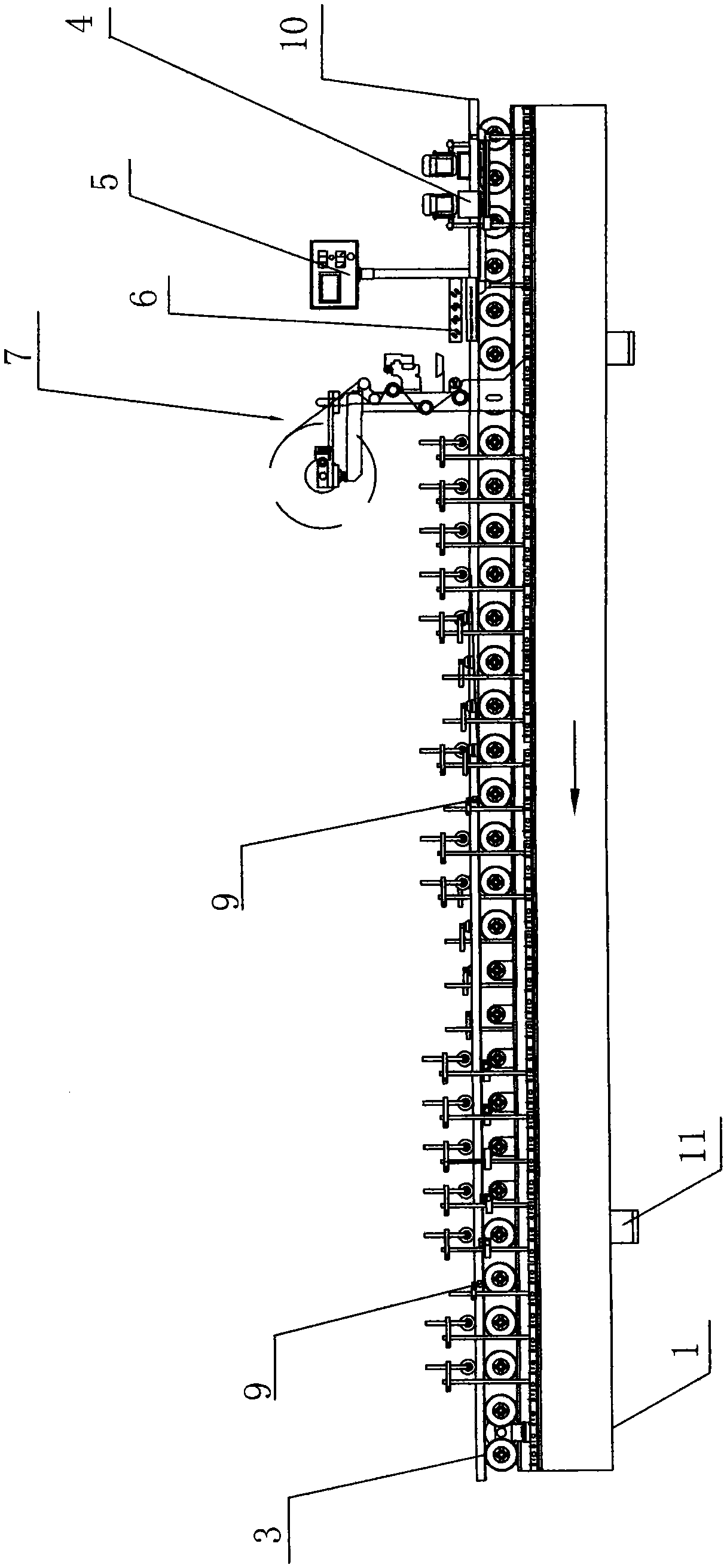

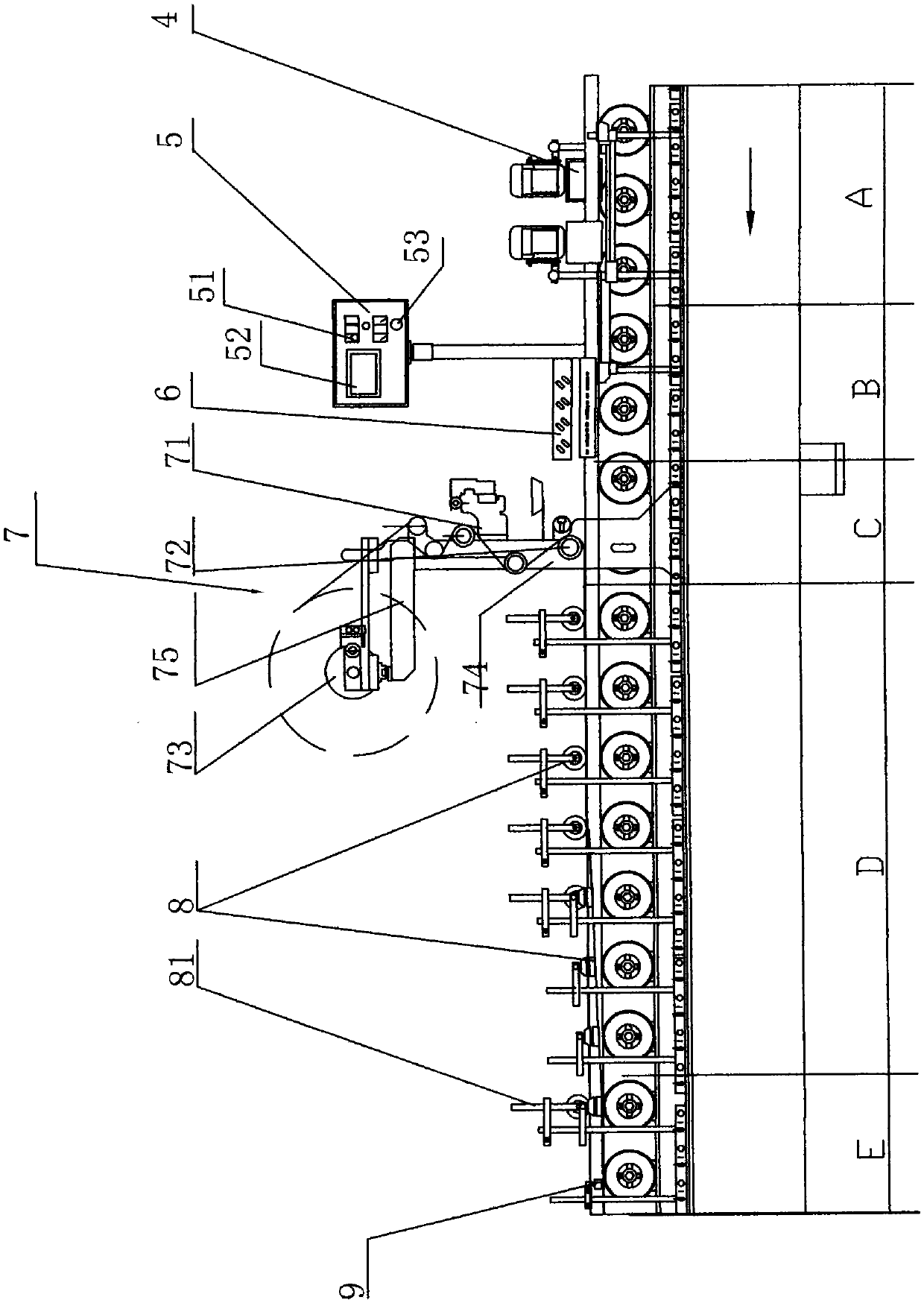

[0035] Such as Figure 1 to Figure 7-6 As shown, a square wood product processing method with cladding, the cladding processing steps include: (a) cleaning the surface of cladding 10, (b) heating the surface of cladding 10, (c) cladding 10 Gluing, (d) paper covering on the upper and left sides of the covering part 10, (f) covering paper on the right side and the lower side of the covering part 10, the covering processing step of a square wooden product processing method with a covering layer also includes (e ) paper cutting for the first time and (g) paper cutting for the second time; the (e) paper cutting step for the first time is carried out on (d) the wrapping part 10, after the paper covering step on the left side, and the (g) the first time The second paper cutting step is carried out aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com