Anilox roller, particularly for flexographic printing machines

A technology of anilox roller and flexographic plate, which is applied to printing machines, general parts of printing machinery, rotary printing machines, etc. It can solve the problem of low thermal conductivity of the sleeve, which cannot meet the special needs of flexographic printing machines, and the energy efficiency is not particularly high, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

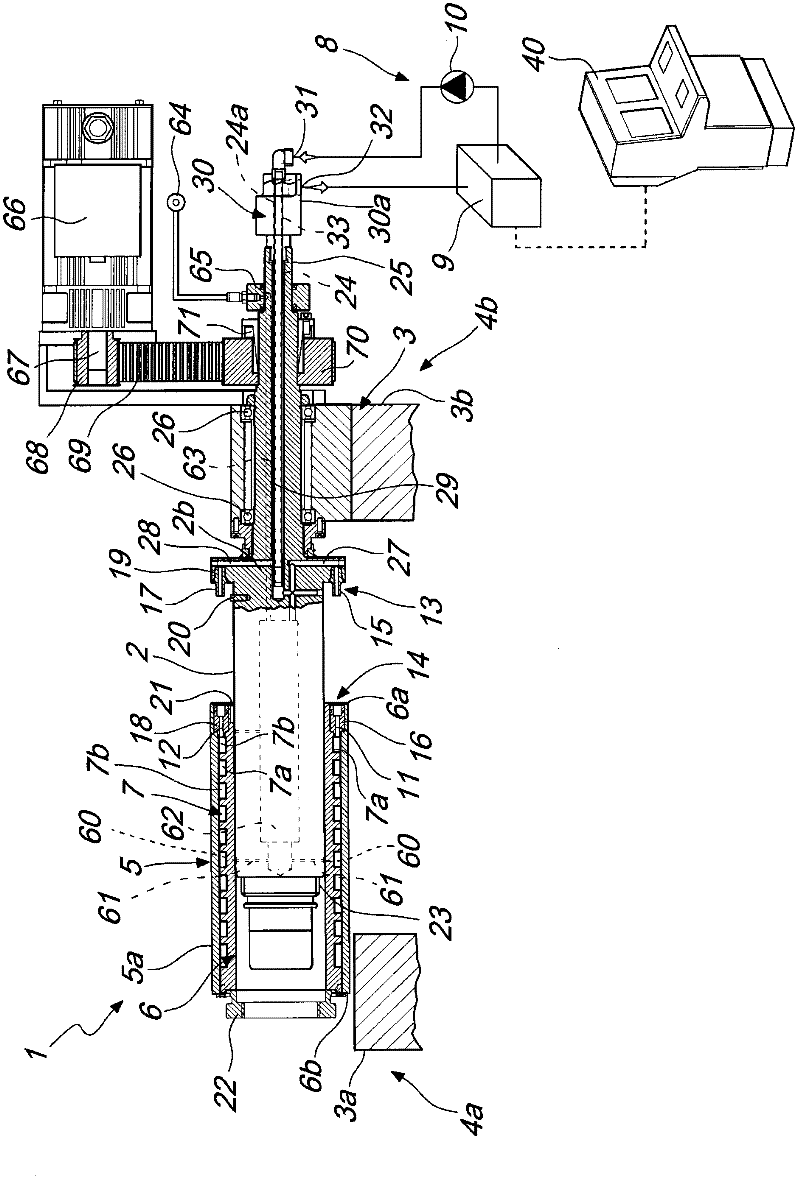

[0029] With reference to these figures, an anilox roll, in particular for a flexographic printing machine, is indicated generally by the reference numeral 1 and comprises a sleeve cylinder 2 which is driven around its own axis by a flexographic printing machine. 4 fixed structure 3 rotating support.

[0030] In general, the flexographic printing press 4 expediently has a front side 4a, on which the operator can access the sleeve cylinder 2, and a rear side 4b, which is opposite the front side.

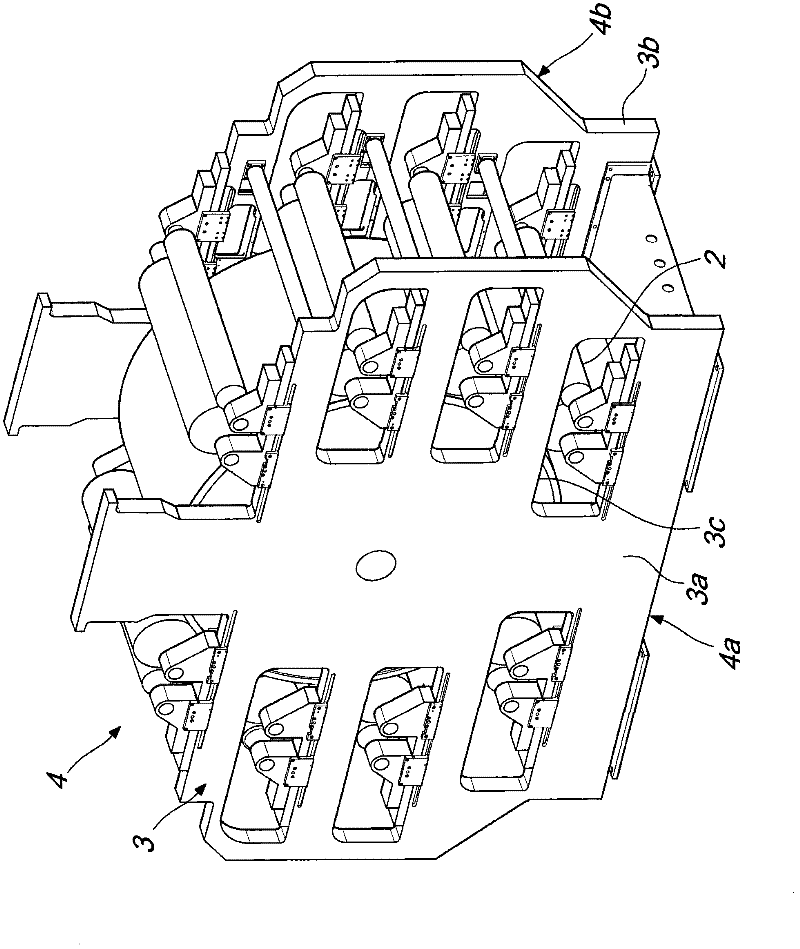

[0031] Preferably, the fixed structure 3 of the flexographic printing machine 4 comprises a first support shoulder 3 a and a second support shoulder 3 b, which are substantially parallel to each other and spaced from each other along the axis of the sleeve cylinder 2 . More specifically, a first support shoulder 3a is provided on the front side 4a of the flexographic printing press 4 and suitably has at least one opening 3c for access to the sleeve cylinder 2, while a second support sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com