Micro wheel-side structure of automobile axle

A technology for miniature cars and axle wheels, applied in the directions of wheels, axles, vehicle parts, etc., can solve problems such as difficulty in disassembling the wheel side, lubricating oil entering the brake, and inconvenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

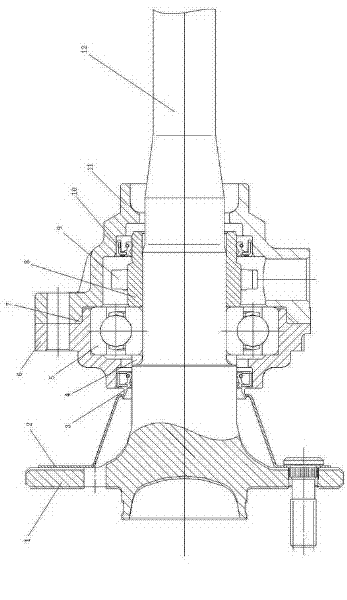

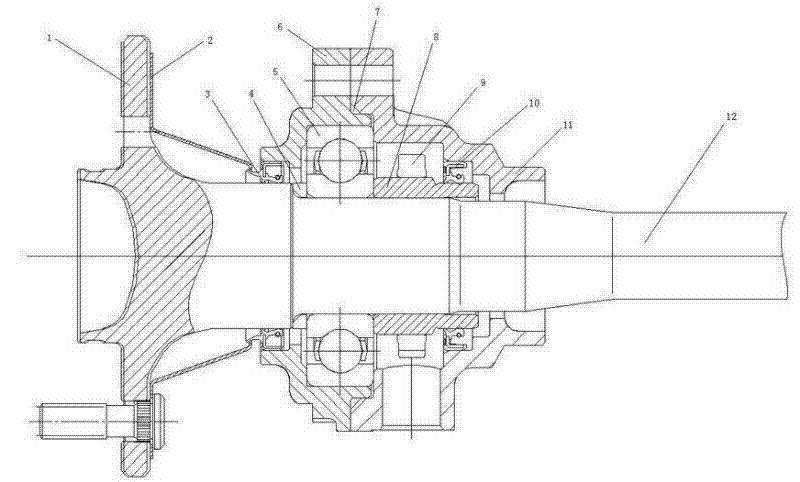

[0015] In the present invention, an oil throwing pan 2 is installed on the flange 1 of the half shaft 12, one end of the oil throwing pan 2 is lapped on the inner oil seal 3, the bearing 5 is set on the half shaft 12, and the outer ring of the bearing 5 is fixedly connected with the bearing seat 6 , the inner oil seal 3 is stuck between the bearing seat 6 and the half shaft 12, the inner ring of the bearing 5 is clamped by the bearing stop ring 4 and the positioning ring 8, the ring gear 9 clamps the positioning ring 8, the bearing seat 6 is connected with the shaft head 11, An outer oil seal 10 is stuck between the shaft head 11 and the positioning ring 8 .

[0016] The present invention has an O-shaped sealing ring 7 at the joint between the bearing seat 6 and the shaft head 11 .

[0017] The bearing seat of the present invention effectively compresses the outer ring of the half-shaft bearing, realizing reliable compression of the half-shaft bearing; adopting the bearing sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com