A kind of alloy inlaid dust-free rock wool cutting knife and its processing method

A processing method and cutting knife technology, applied in metal processing and other directions, can solve the problem of excessive dust, and achieve the effects of reducing noise, improving the convenience of disassembly and assembly, and increasing the reuse rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

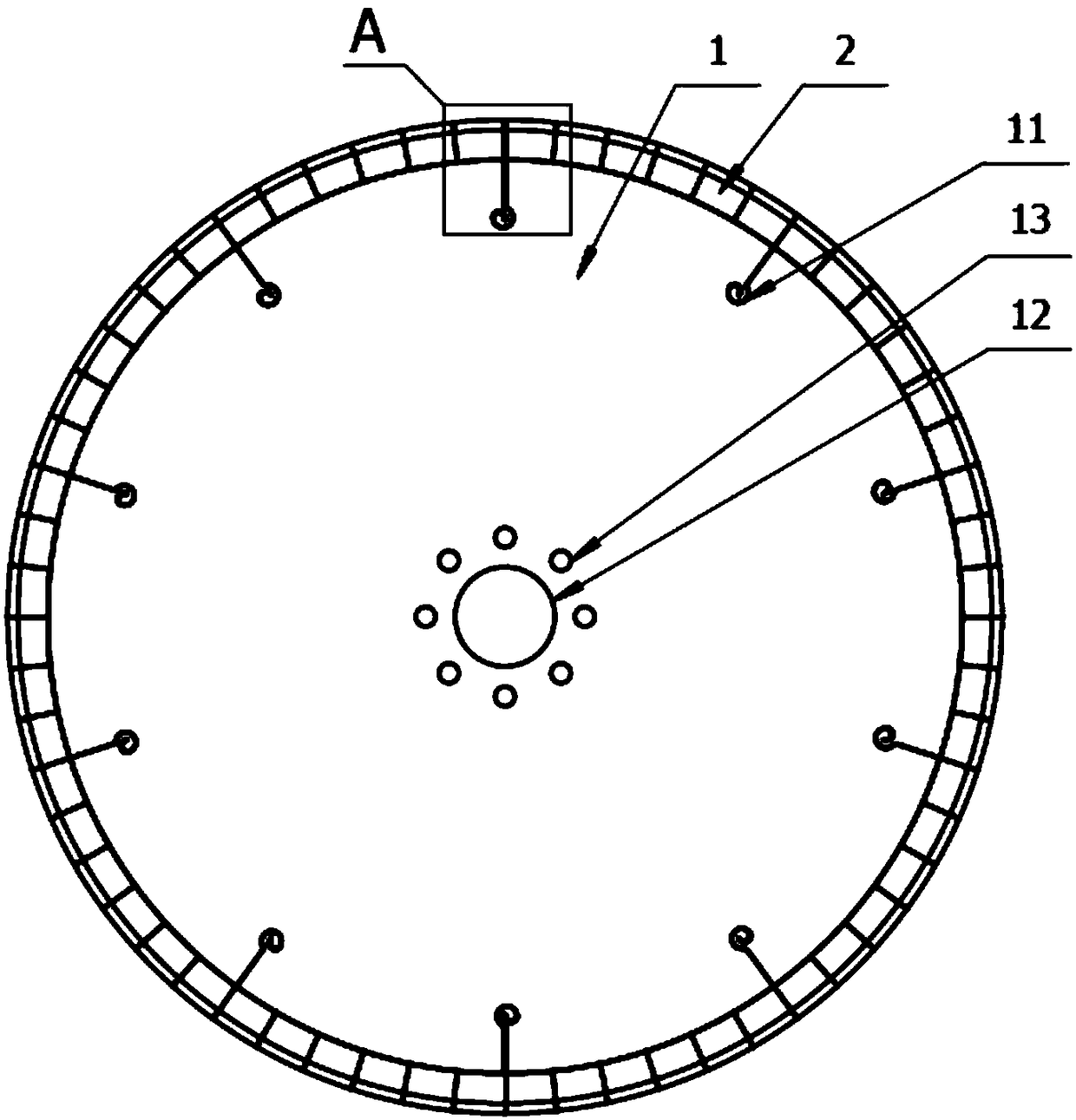

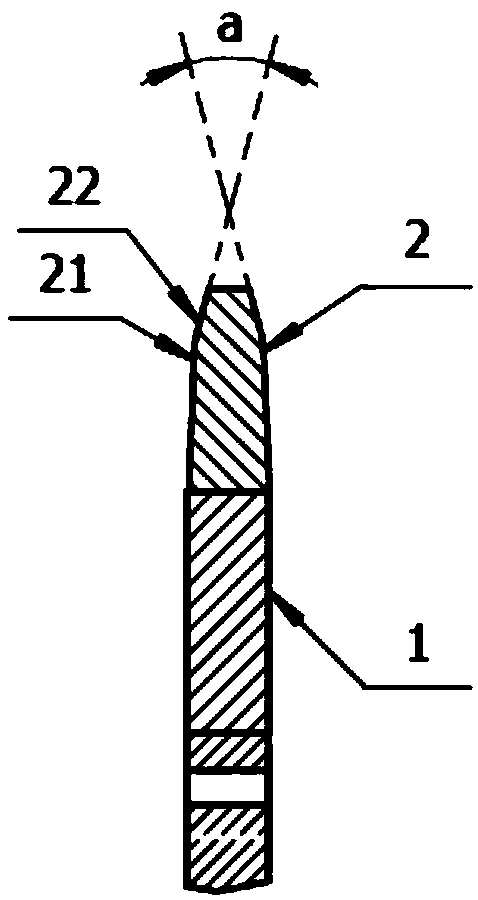

[0045] Such as figure 1 , figure 2 As shown, an alloy-inlaid dust-free rock wool cutting knife includes a knife body 1 and a blade 2, the knife body 1 is circular, the blade 2 is arc-shaped, and the blade 2 is connected to the outer surface of the knife body 1 in turn.

[0046] The blade 2 is arc-shaped segment by segment. Compared with the entire annular blade, the processing is more convenient. When die forging is used for processing, the size of the die is smaller. And when there is a gap in the blade 2, the section of the blade 2 at the gap can be removed, and a new blade 2 can be replaced, so that the whole cutter can be reused.

Embodiment 2

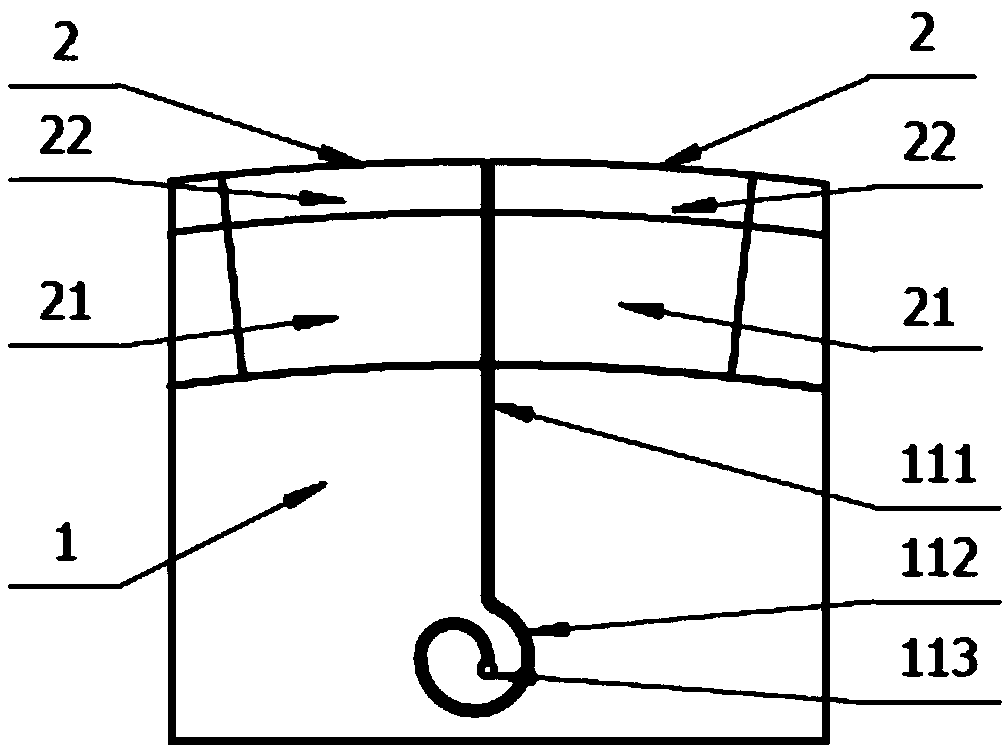

[0048] An alloy-inlaid dust-free rock wool cutting knife of this embodiment is similar to Embodiment 1, the difference is that this embodiment also includes a sound-absorbing groove 11, and the sound-absorbing groove 11 is evenly distributed on the knife body 1 and the blade 2, The sound-absorbing groove 11 runs through the cutter body 1 and the blade 2. The sound-absorbing groove 11 includes a central hole 113, a helical section 112 and a straight section 111. The helical section 112 connects the central hole 113 and the straight section 111 as a whole, and the central hole 113 and the helical section 112 Located on the cutter body 1 , the straight section 111 runs through the blade 2 and extends to the cutter body 1 .

[0049] In this embodiment, the straight line section 111 of the silencer groove 11 located on the blade 2 is located at the weld between two blades 2. Since the material of the weld is relatively soft, the processing is convenient, which further improves the p...

Embodiment 3

[0052] An alloy-inlaid dust-free rock wool cutting knife of this embodiment is similar to that of Embodiment 2, except that the knife body 2 also includes a shaft hole 12 and a connecting hole 13, and the shaft hole 12 is located at the bottom of the knife body 2. At the center of the circle, the connecting holes 13 are evenly distributed outside the shaft hole 12 , and the circle formed by the centers of all the connecting holes 13 is concentric with the shaft hole 12 .

[0053] In this embodiment, a shaft hole 12 is provided at the center of the cutter body 2 to facilitate the connection between the cutter and the power device, and the cutter can be quickly fixed on the power device through the connection hole 13, which improves the convenience of disassembly and assembly of the cutter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com