Design method for multifunctional helicopter

A design method and technology of helicopters, applied in the direction of rotorcraft, motor vehicles, aircraft, etc., can solve the problems of increasing the total power consumption and weight of the whole machine, complexity, and bulky duct walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

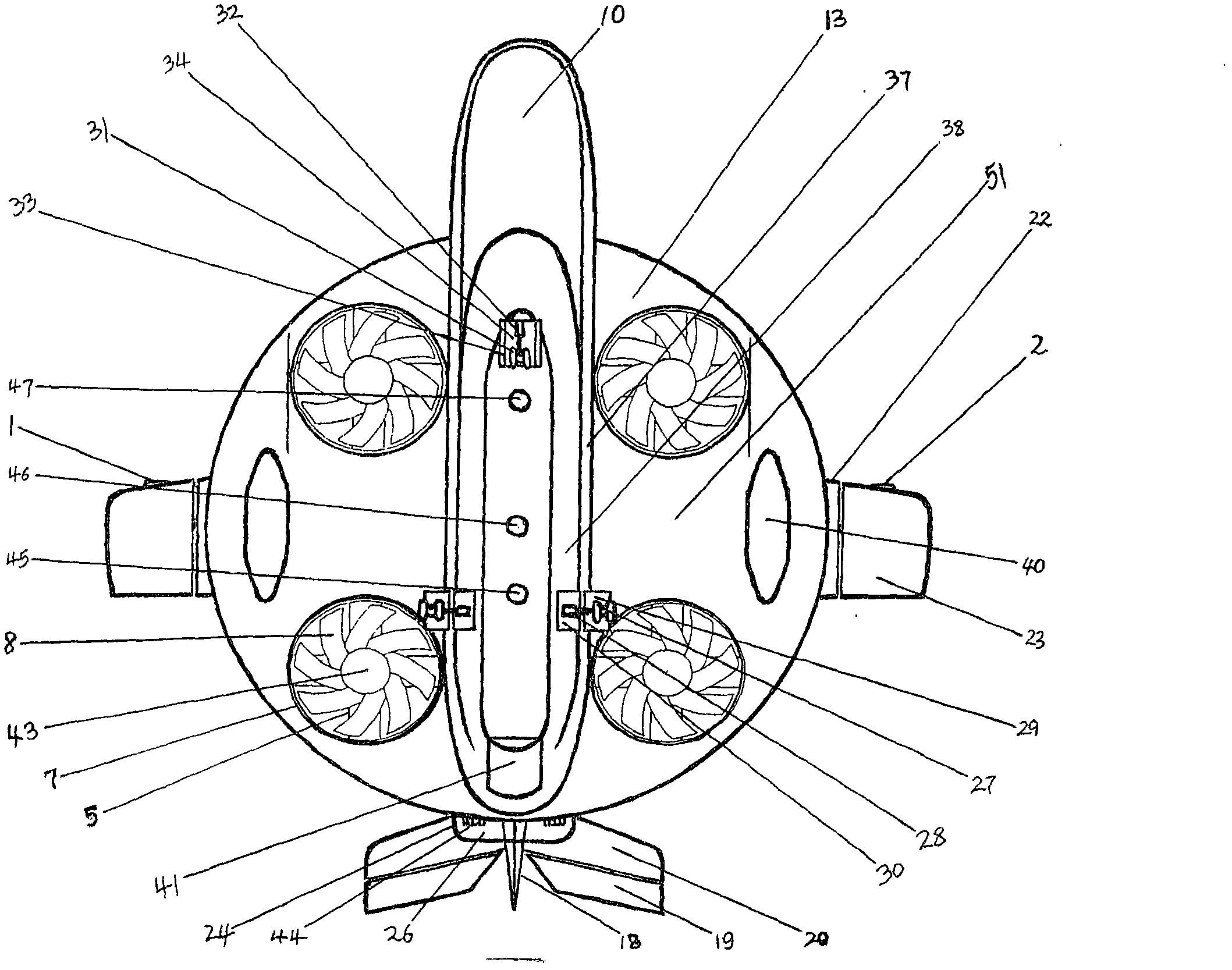

[0031] 1. Identify enterprises with implementation capabilities: 1-Enterprises that use composite materials to design and manufacture various aircraft fuselages. 2-Enterprises that design and manufacture various hulls using composite materials. 3-Enterprises that design and manufacture various large-scale composite material accessories. 4-Enterprises that design and manufacture various aircraft fuselages. 5-Large and medium-sized enterprises with various research and development capabilities. Because the investment in designing and manufacturing aircraft is relatively huge, other small companies that are not related to it will not have the ability to implement it.

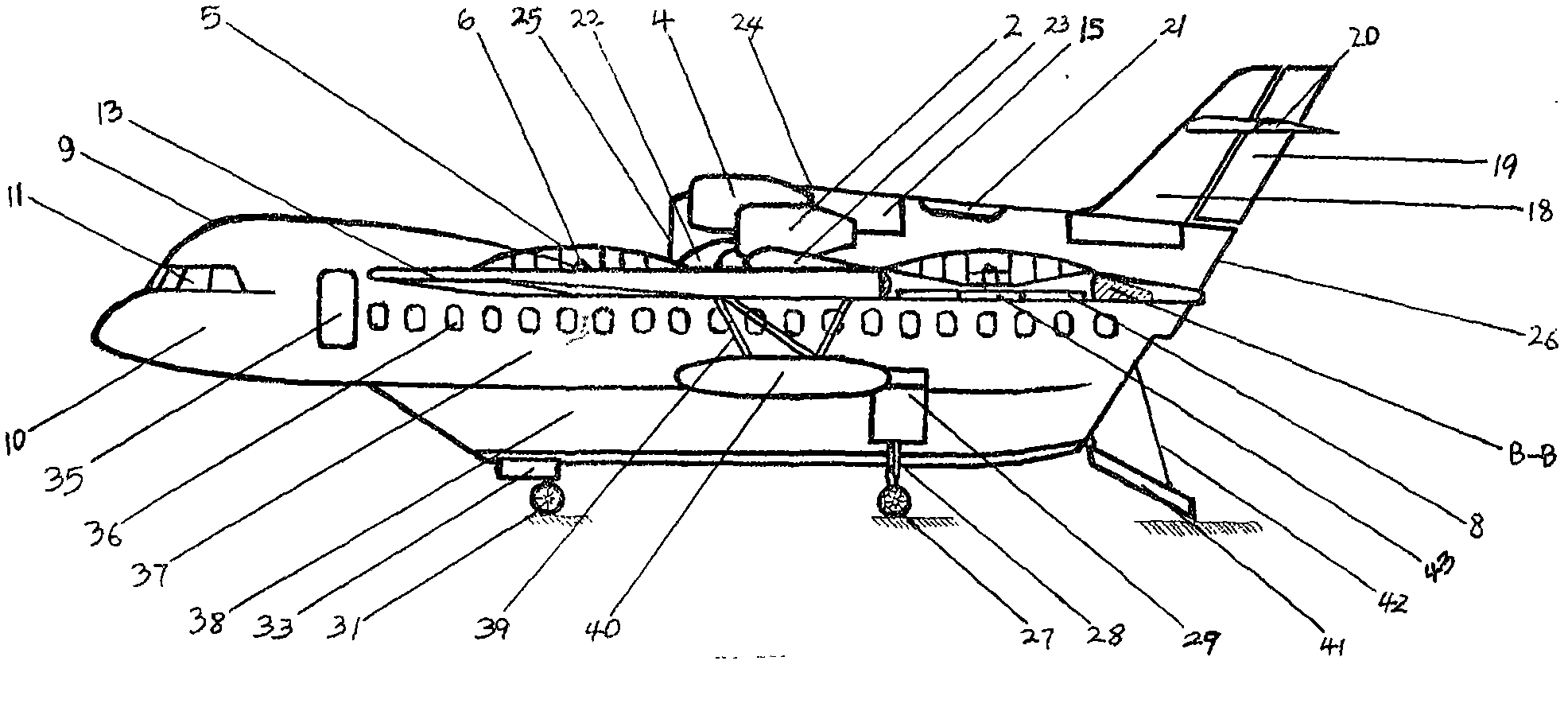

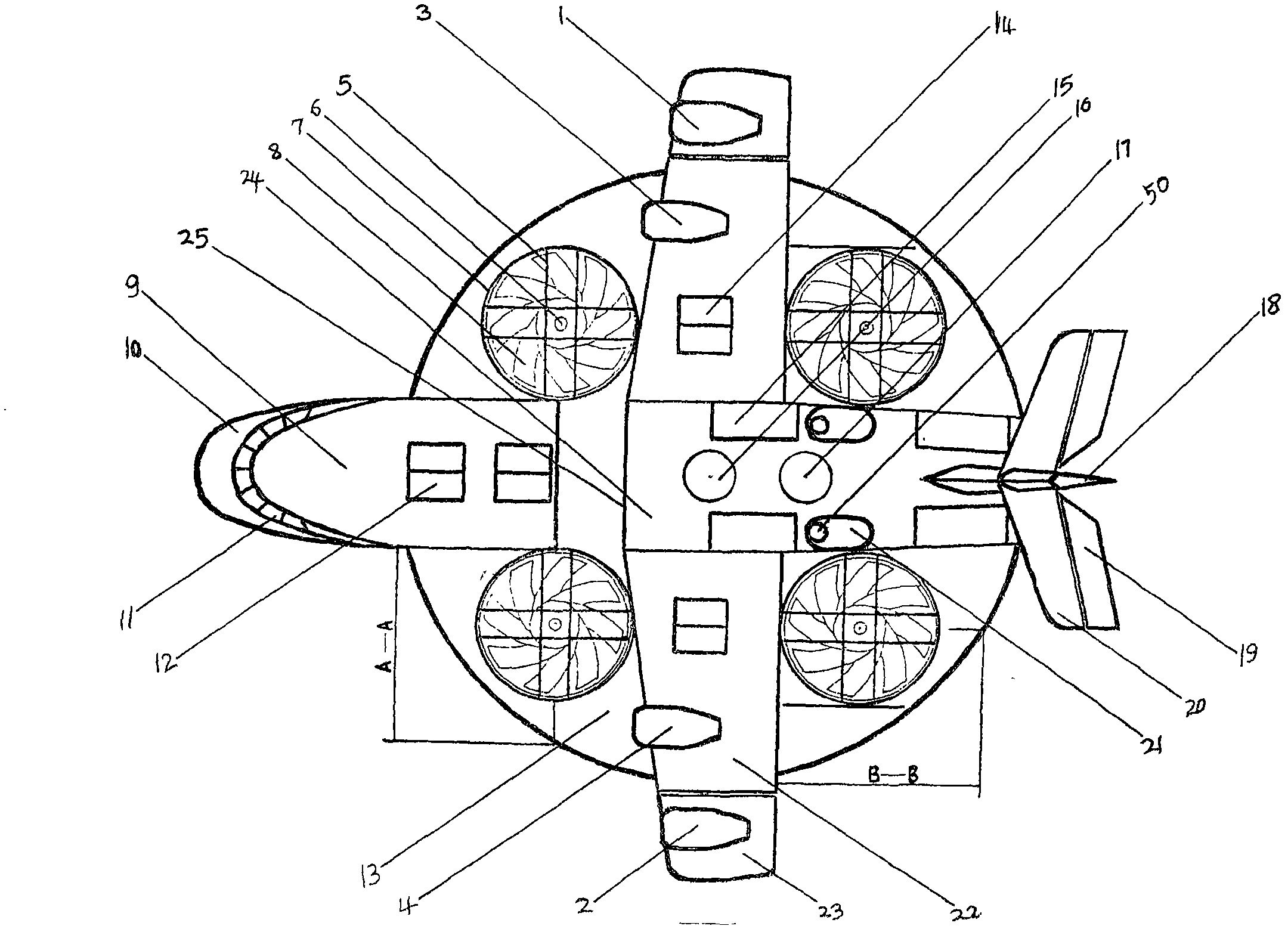

[0032] Two, determine design scheme and requirement: in order to reach the purpose of implementing zero risk of the present invention, begin by the design and manufacture of the smallest multifunctional helicopter earlier, then develop toward large multifunctional helicopter design and manufacture direction on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com