Transversely-sealing and longitudinally-sealing transmission system of intermittent type packer and control method for same

A technology of transmission system and mechanical horizontal sealing, which is applied in the field of packaging machinery and equipment, and can solve the problems of inability to ensure fast opening and sealing of horizontal sealing and vertical sealing, large precision error of bag length, and increase of pulling time of longitudinal sealing and pulling bags and other problems, to solve the problem of vulnerable heating rods, improve the production and assembly cycle, and speed up the effect of the production and assembly cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

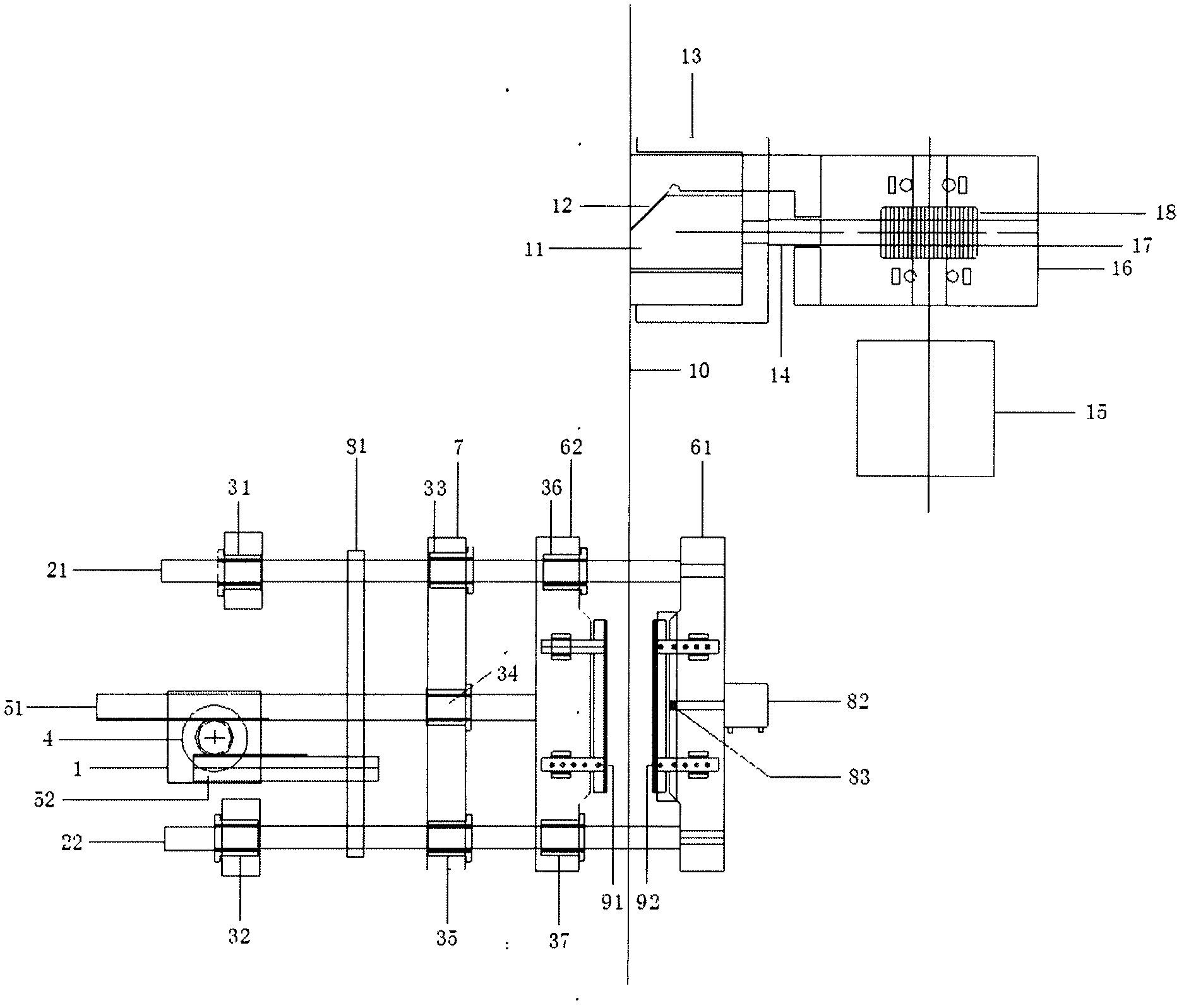

[0041] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0042] Such as figure 1The transmission system for horizontal sealing and vertical sealing of an intermittent packaging machine shown includes a horizontal sealing stepping motor, a horizontal sealing transmission mechanism, a horizontal sealing heating rod, a vertical sealing stepping motor, a vertical sealing transmission mechanism and a longitudinal sealing heating rod , the horizontal seal transmission mechanism includes a horizontal guide gear, a horizontal guide gear shaft, a horizontal linear guide rail, a linear bearing and a horizontal seal movable support frame, and the horizontal guide gear 4 is fixed on the motor shaft of the horizontal seal stepping motor 1, and the horizontal The guide gears cooperate with the first transverse guide pinion 51 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com