Dual-blind flange sterilizer with microwave drying function

A technology for microwave drying and sterilizing machines, which is applied in the direction of drying machines, drying, hearth type furnaces, etc., and can solve the problems of shortened lifespan, large equipment footprint or space, and long sterilization and drying time, etc. problems, to achieve the effect of prolonging the service life, less auxiliary equipment, and high sterilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

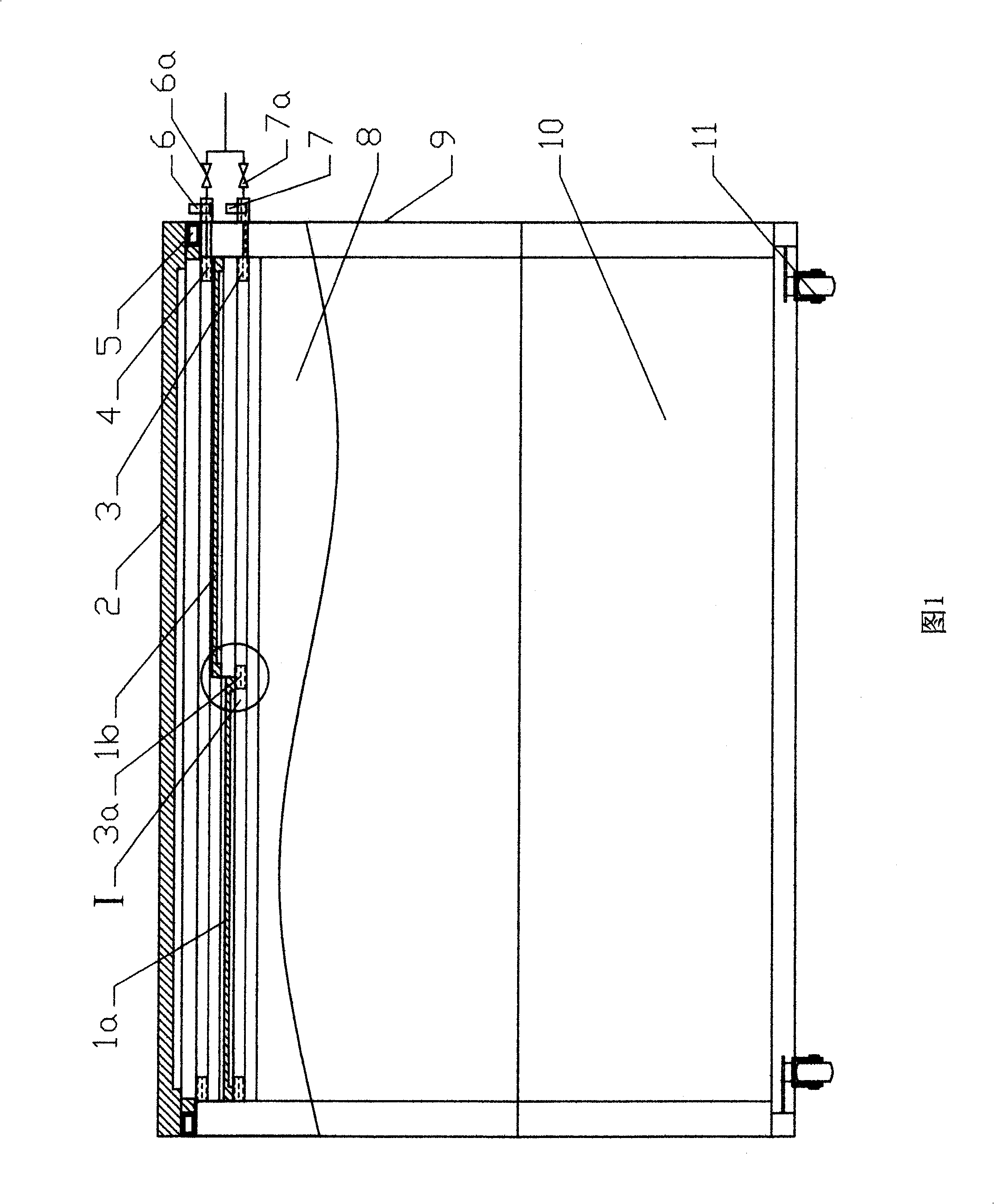

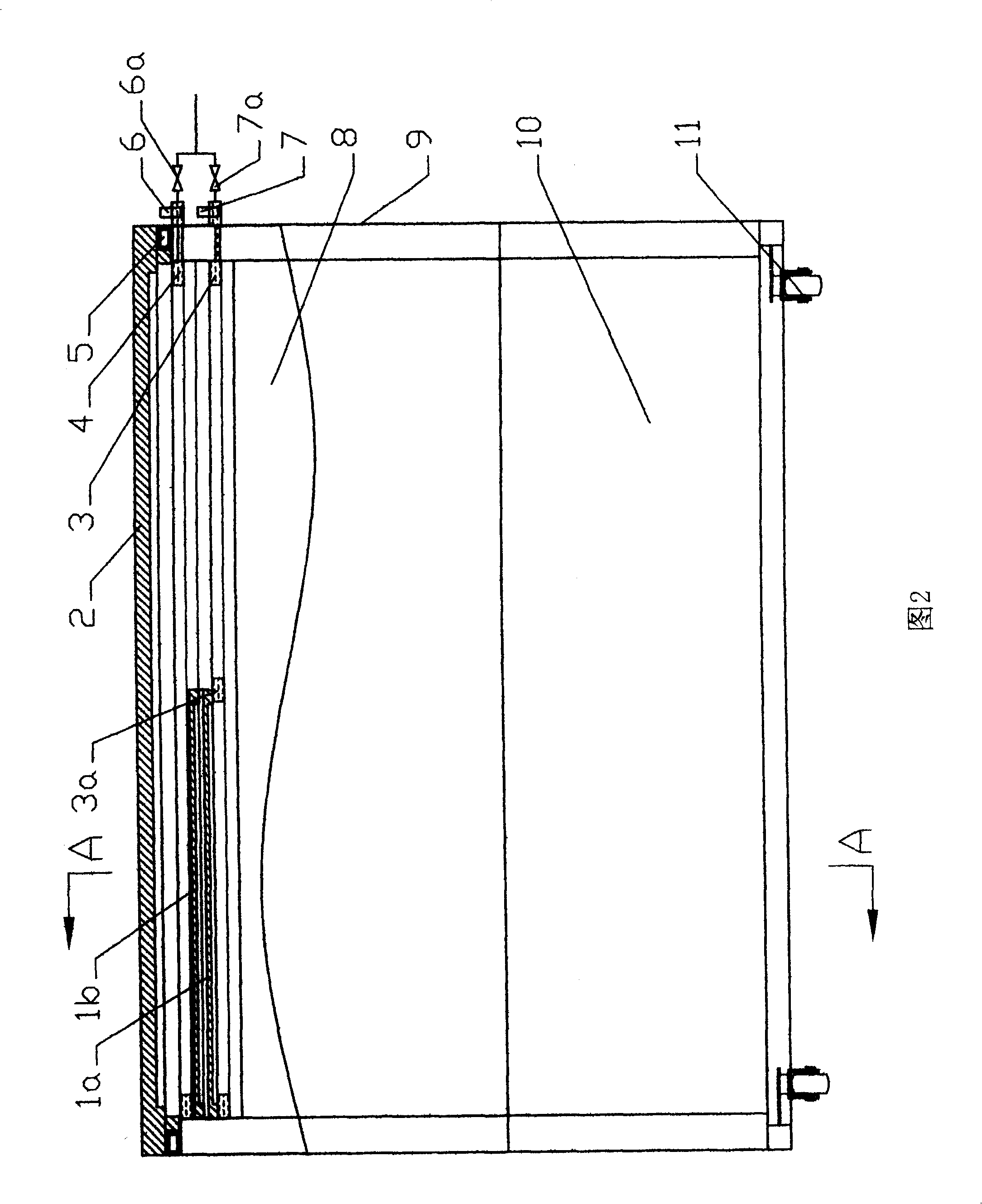

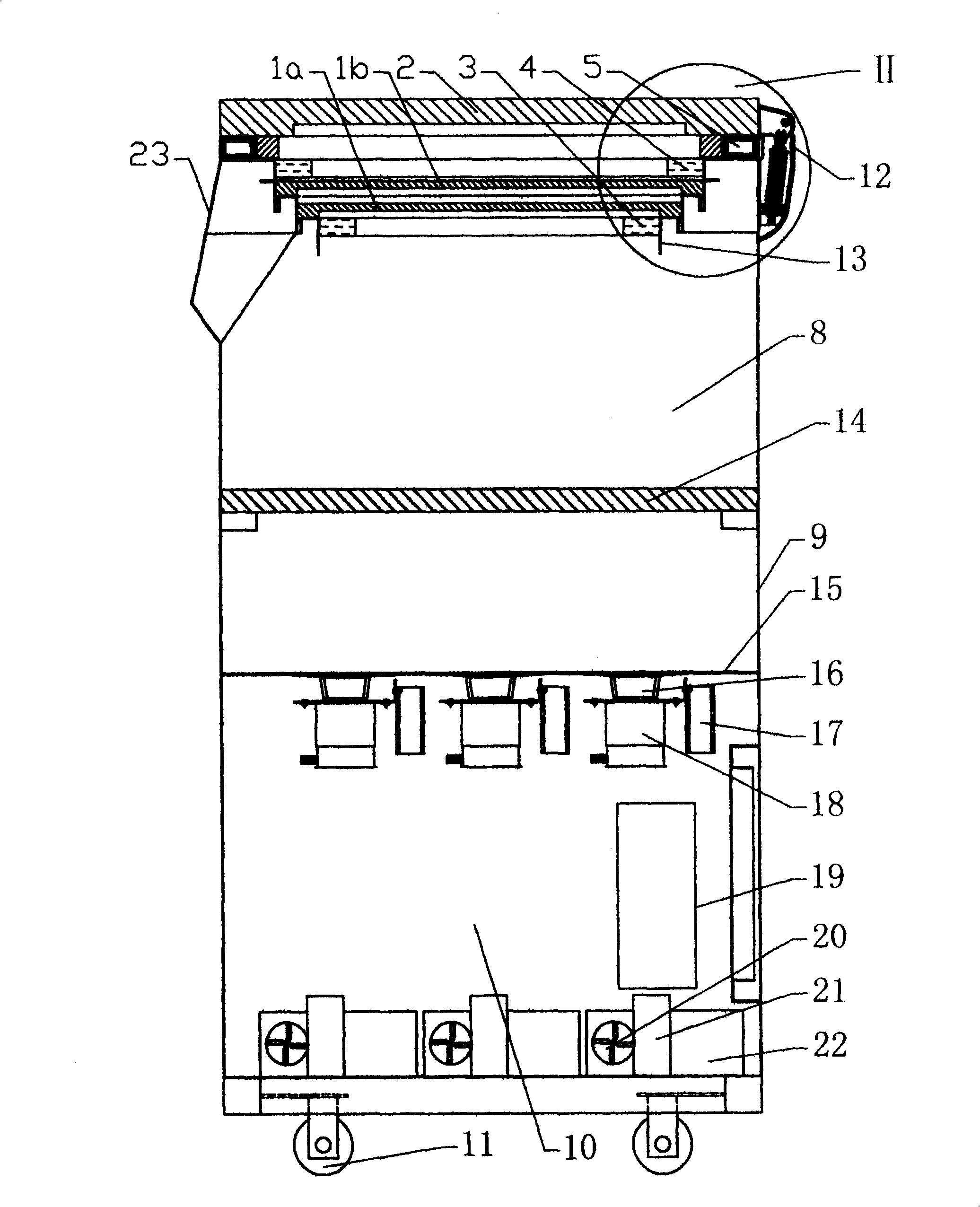

[0018] Embodiment 1. The structure of the double cover type microwave drying and sterilizing machine of the present embodiment can be seen from Fig. 1 and image 3 As can be seen in the figure, it contains wheels 11, a cabinet 9, and a control panel 23. The cabinet 9 is divided into two cavities by an intermediate plate 15, wherein the upper cavity is a microwave heater 8, and the lower cavity is an equipment cavity 10. The microwave working unit and the control cabinet 19 that emit microwaves to the microwave heater 8 are placed in the equipment cavity 10. The microwave working unit includes a magnetron 18, a waveguide 16, a centrifugal fan 17, a high-voltage transformer 22, an axial fan 20 and a capacitor 21; The doorway of the microwave heater 8 is upwards, and an outer cover plate 2 is hinged by a large drug skin 12 at the doorway. Above the opening of the microwave heater 8, a microwave absorbing cavity 5 is installed, and there is a surrounding frame 2a on the bottom surf...

Embodiment 2

[0024] Embodiment 2. The structure of the double cover type microwave drying and sterilizing machine of this embodiment can be seen from Fig. 6 and Figure 8 It can be seen from the figure that it is different from Embodiment 1 in that three steps 13a and three absorbing grooves 13b are arranged on the track 13, and three movable inner cover plates of the same length are placed in sequence on the three steps 13a , that is, the upper inner cover 1b, the middle inner cover 1c and the lower inner cover 1a, there is a downward retaining bar 24 on the side of the upper inner cover 1b perpendicular to the track 13, and the lower inner cover 1a and the track There is an upward retaining strip 25 on the vertical side of 13, and an upward and downward retaining strip is respectively arranged on the two sides perpendicular to the middle inner cover plate 1c and the track 13, so that when the 3 inner cover plates are completely closed, they will be in contact with each other. Pulled by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com