Marine product packaging bag

A packaging bag and seafood technology, applied in the field of seafood packaging bags, can solve the problems of low efficiency and complicated production process, and achieve the effect of low cost, simple production process and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

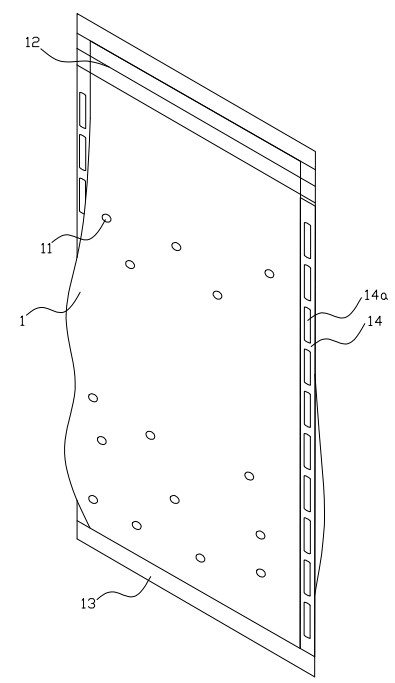

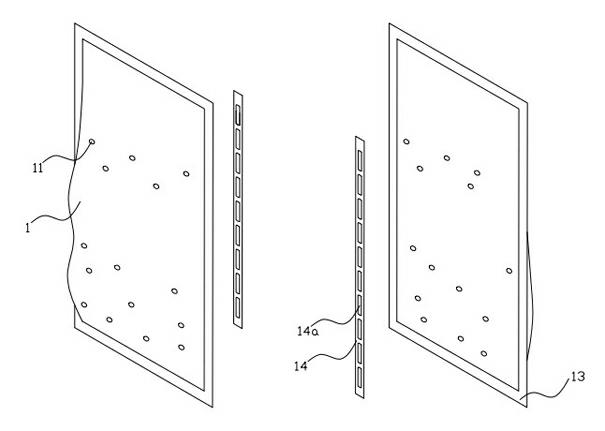

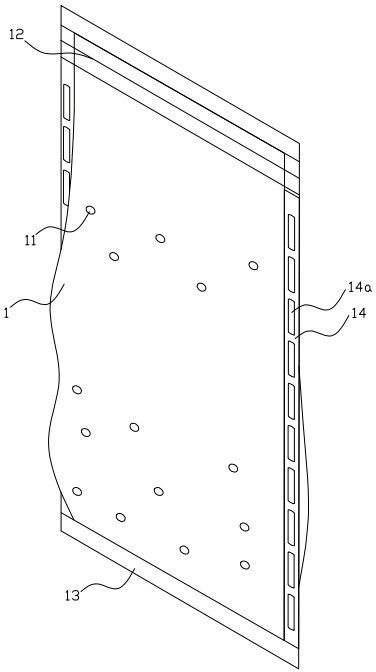

[0011] Example: refer to Figure 1 to Figure 2 , a seafood packaging bag, having a bag body formed by pressing two pieces of plastic film 1, wherein: the side of the plastic film 1 is provided with a water seepage paper tape 14; the water seepage paper tape 14 is formed with a bonding hole 14a, which is located in the bonding hole 14a Parts of the plastic film 1 are bonded to each other; the water in the inner chamber of the bag can be discharged to the outside of the bag through the water-permeable paper tape 14; the bottom of the bag has a sealing line 13; The 11 bags with water leakage holes can quickly discharge excess water, and can play a role in ventilation during long-term transportation. One side of the water-permeable paper tape 14 is located in the cavity of the bag body, and the other side is located outside the bag body, so that water vapor and condensed water can be discharged out of the bag body at a slower speed through the permeation of the edge. Parts of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com