Dismounting wharf crane

A detachable and wharf technology, which is applied to cranes and other directions, can solve the problems of difficulty and low rigidity of corrosion-resistant steel, and achieve the effects of convenient operation, quick installation and disassembly, and improved stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

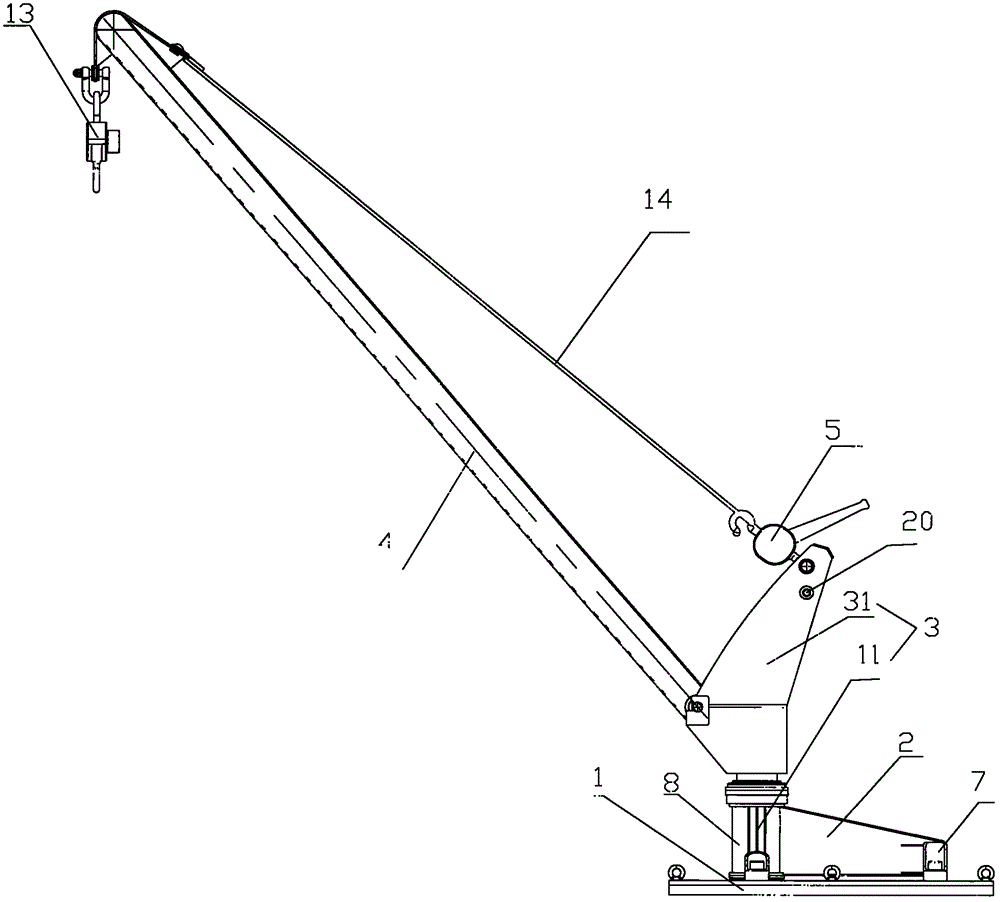

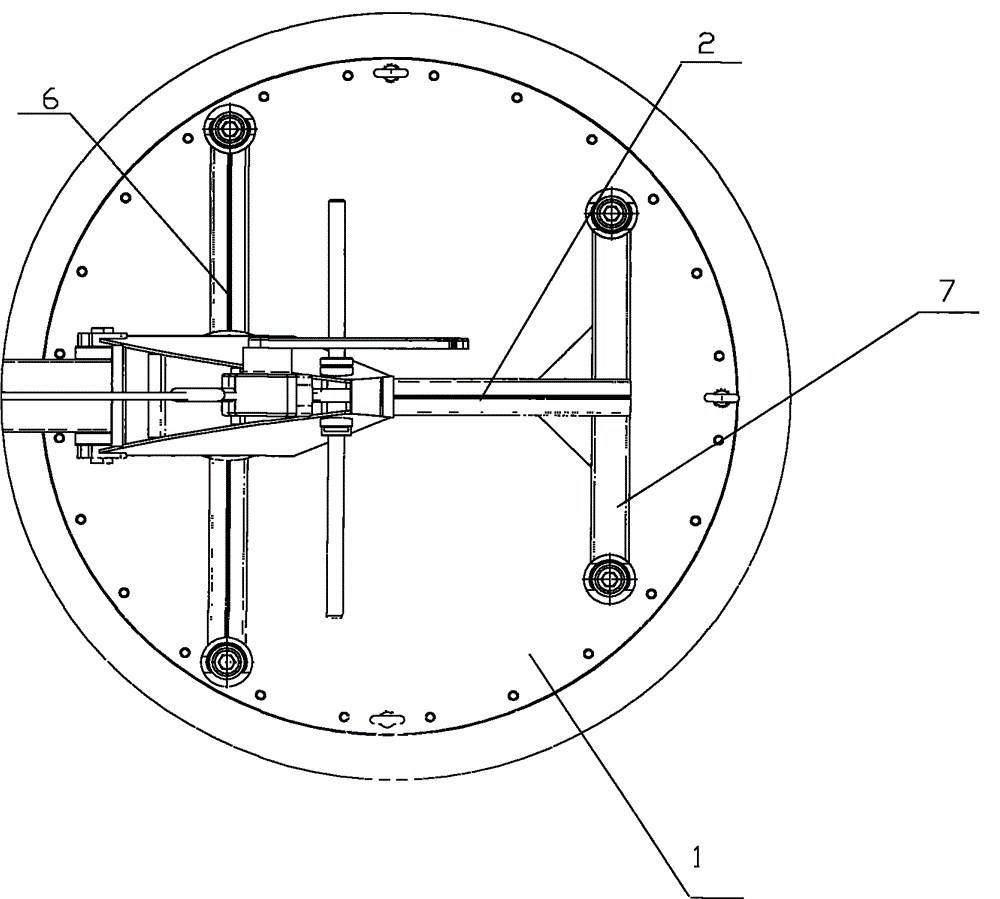

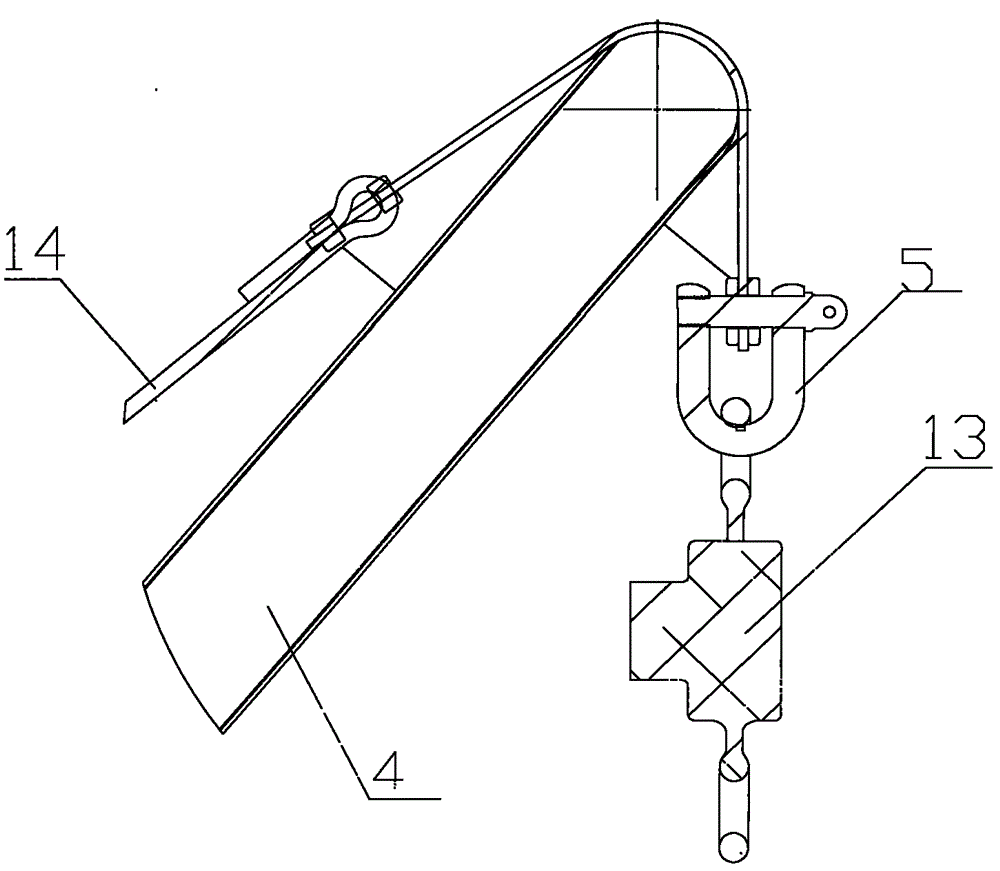

[0027] figure 1 It is a schematic diagram of a detachable wharf crane according to an embodiment of the present invention. figure 2 is a schematic diagram of the chassis according to the embodiment of the present invention. image 3 It is a partially enlarged schematic diagram of the boom according to the embodiment of the present invention. Figure 4 It is a partial cross-sectional schematic view of the base according to the embodiment of the present invention. Figure 5 It is a schematic diagram of a structural model of a two-story platform detachable dock crane according to the embodiment of the present invention. Image 6 is a structural schematic diagram of the rotating shaft according to the embodiment of the present invention. Figure 7A is a schematic diagram of the connecting shaft provided at the first end of the boom according to the embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com