Micro-sand synergism and caked flocculation integrated water quality purification device

A water purification and integrated technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problem of high workload, achieve the effects of reducing the occupied area, increasing the effective density, and facilitating operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

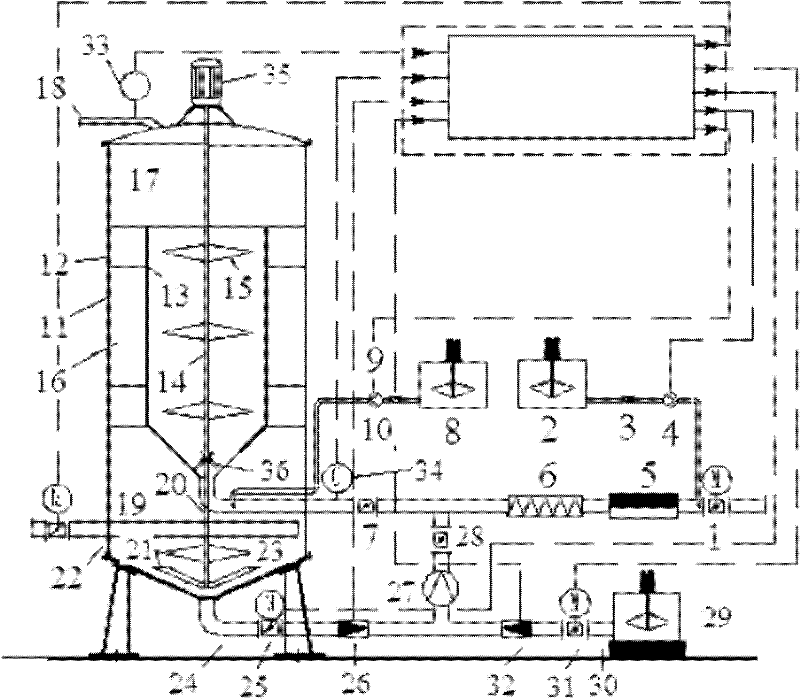

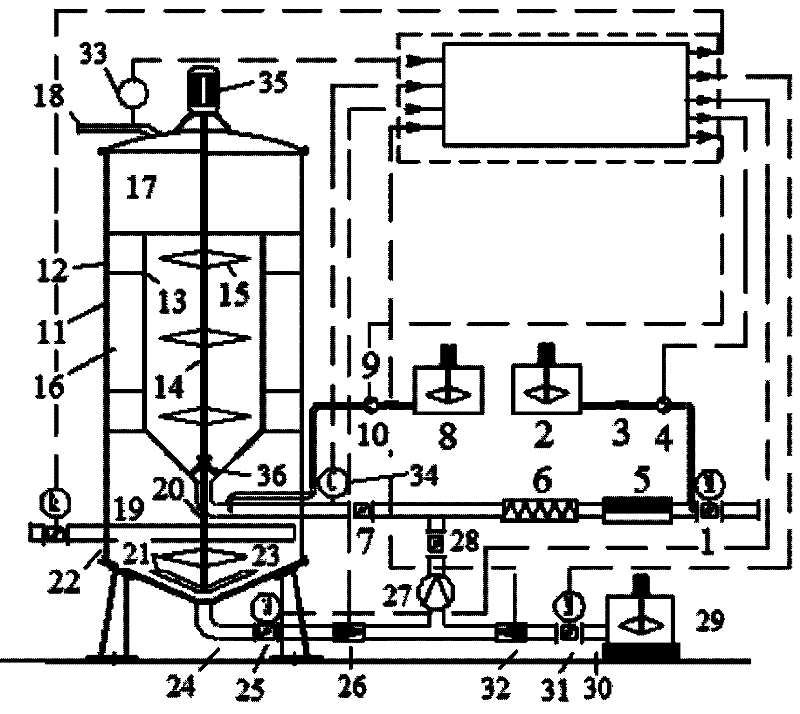

[0027] refer to figure 1 , this embodiment provides a microsand synergistic agglomeration and flocculation integrated water purification equipment, including main equipment, water inlet pipelines, microsand recycling pipelines and an automatic control system.

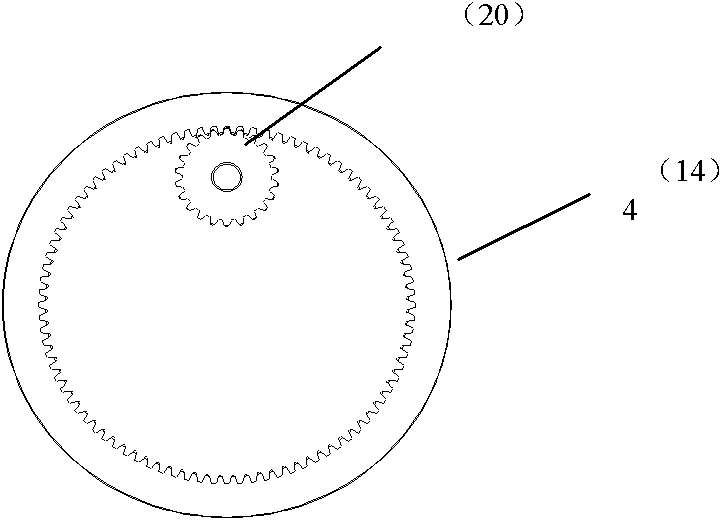

[0028] The main equipment is an inner and outer cylinder structure, in which the inner cylinder 13 is the agglomeration and flocculation area, and the outer cylinder 11 is divided into a clear water area 17, a solid-liquid separation area 16, a mud-sand separation area 19, and a sand collection area 23 from top to bottom. The top of 17 is provided with a clear water outlet pipe 18, the bottom of the mud-sand separation area 19 is provided with a slit discharge pipe 22, and the sand collection area 23 is provided with a micro-sand circulation pipe 22; the top of the main equipment is provided with a driving motor 35, which is used to Drive the reaction stirring shaft 14 and the separation stirring shaft 20 arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com