Gypsum-based paraffin phase-changing energy-storing wall board and manufacture method thereof

A phase-change energy storage, gypsum-based technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of expensive materials, leakage of liquid phase-change materials, complex processes, etc., to achieve low prices and reduce construction costs. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

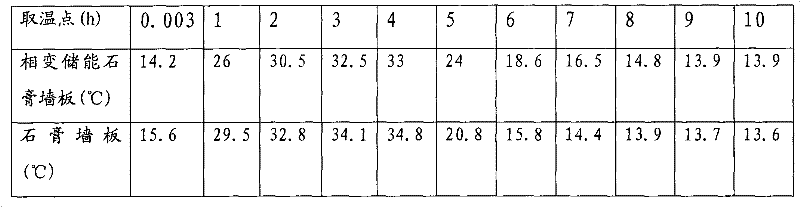

Embodiment 1

[0021] A gypsum-based paraffin phase-change energy-storage wallboard is prepared by using porous matrix paraffin phase-change energy-storage composite material particles, tap water and gypsum powder. The porous matrix paraffin phase-change energy storage composite material particles are mixed by stirring the porous matrix and the paraffin phase-change material, and at a temperature of 60-70°C, at a constant temperature for 15-20 hours, the porous matrix fully absorbs the paraffin phase-change material, making the paraffin The phase change material can enter into the internal pores or interlayer structure of the porous matrix to prepare the paraffin phase change energy storage composite material particles of the porous matrix. The porous substrate is one or a mixture of wood chips, straw particles, expanded perlite, diatomaceous earth, bentonite or attapulgite with a porous structure. In this embodiment, the porous substrate is made of porous wood chips. The mass ratio of the p...

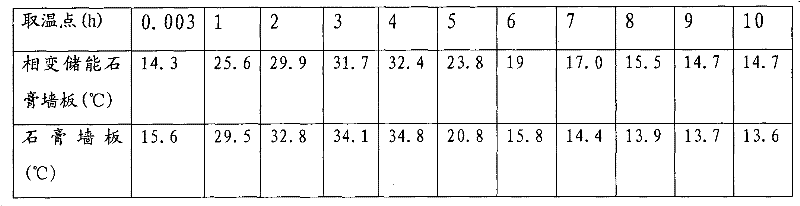

Embodiment 2

[0025] A gypsum-based paraffin phase-change energy-storage wallboard is prepared by using porous matrix paraffin phase-change energy-storage composite material particles, tap water and gypsum powder. The porous matrix paraffin phase change energy storage composite material particles are mixed by stirring and mixing the porous matrix and the paraffin phase change material, at a temperature of 60-70°C, and at a constant temperature for 15-20 hours, and the porous matrix is used to fully absorb the paraffin phase change material. The paraffin phase change material can enter into the internal pores or interlayer structure of the porous matrix to prepare the porous matrix paraffin phase change energy storage composite material particles. The porous substrate is one or a mixture of wood chips, straw particles, expanded perlite, diatomaceous earth, bentonite or attapulgite with a porous structure. In this embodiment, the porous substrate is made of porous wood chips. The mass ratio...

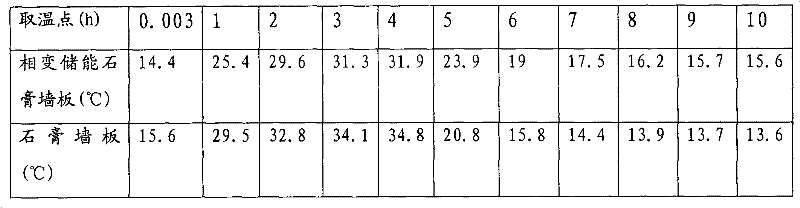

Embodiment 3

[0029] A gypsum-based paraffin phase-change energy-storage wallboard is prepared by using porous matrix paraffin phase-change energy-storage composite material particles, tap water and gypsum powder. The porous matrix paraffin phase change energy storage composite material particles are mixed by stirring and mixing the porous matrix and the paraffin phase change material, at a temperature of 60-70°C, and at a constant temperature for 15-20 hours, and the porous matrix is used to fully absorb the paraffin phase change material. The paraffin phase change material can enter into the internal pores or interlayer structure of the porous matrix to prepare the porous matrix paraffin phase change energy storage composite material particles. The porous substrate is one or a mixture of wood chips, straw particles, expanded perlite, diatomaceous earth, bentonite or attapulgite with a porous structure. In this embodiment, the porous substrate is made of porous wood chips. The mass ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com