Electronic closestool provided with liquid level sensor and preventing liquid level from fluctuating

A liquid level sensor and liquid level fluctuation technology, which is applied to flushing equipment with water tanks, flushing toilets, water supply devices, etc. The effect of malfunction, simplifying the difficulty of manufacturing processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

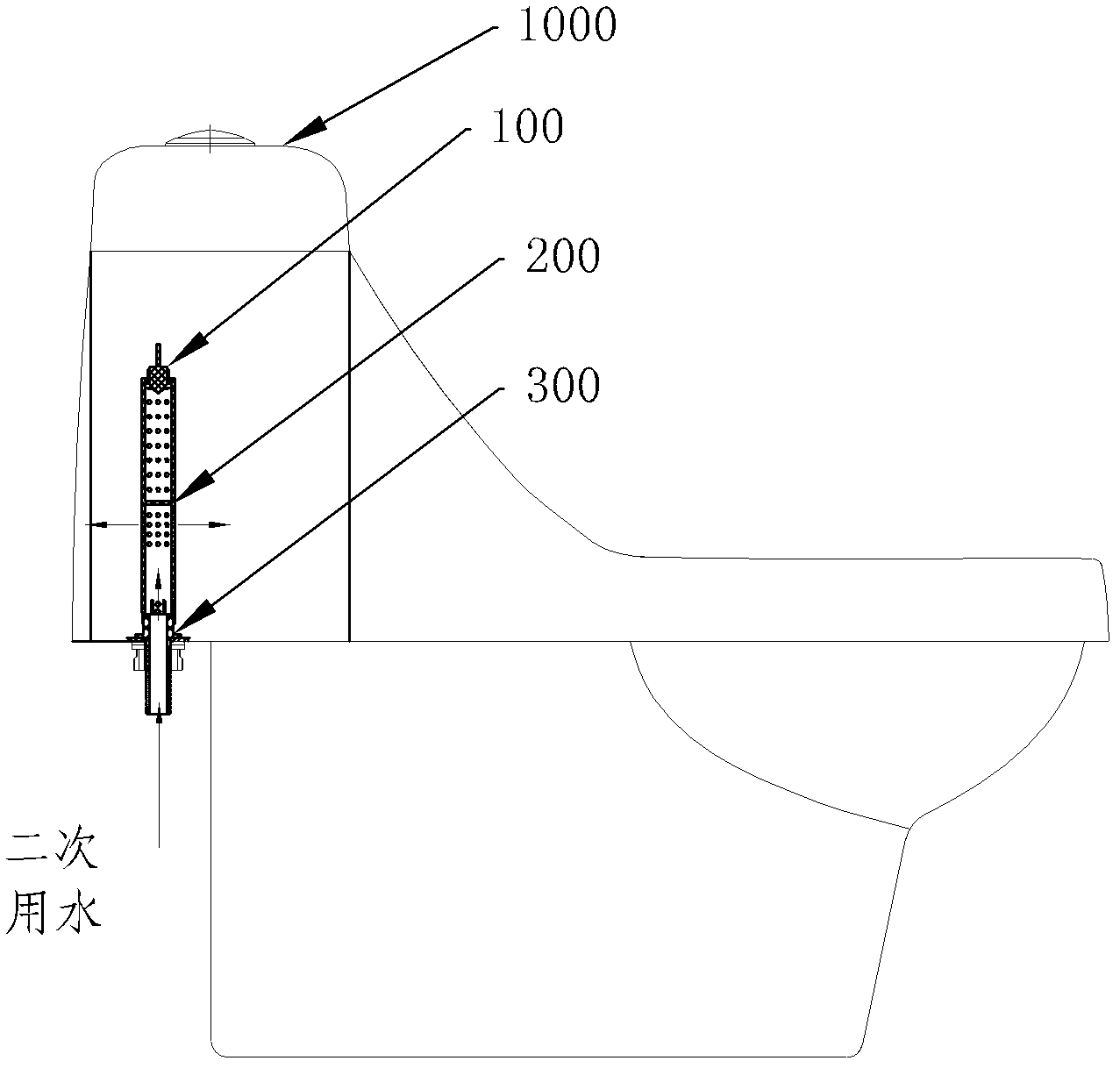

[0020] Such as figure 1 Shown is the toilet 1000 of the present invention, which includes a photoelectric sensor 100 arranged in a toilet tank, a toilet water inlet integration, and a control circuit. The toilet water inlet integration includes a fixing frame 200 and a water inlet assembly 300.

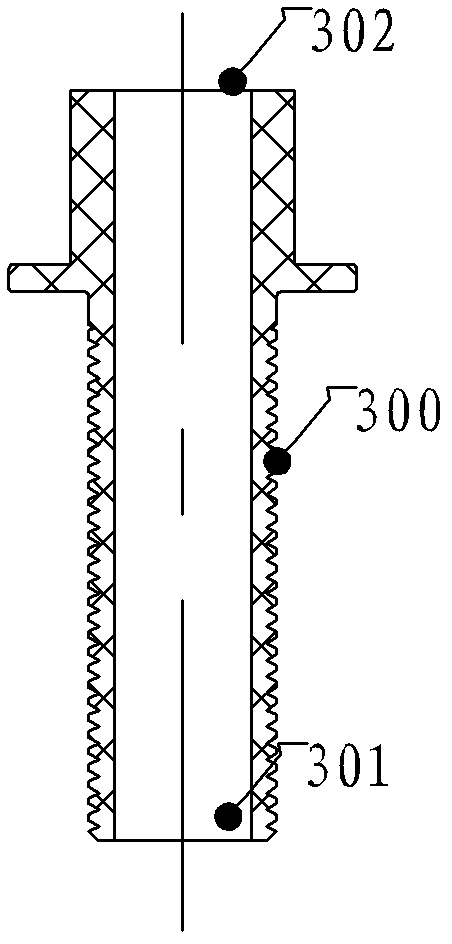

[0021] Such as figure 2 As shown, the water inlet assembly 300 has a tubular body that penetrates from top to bottom. The lower pipe mouth of the tubular body is the water inlet 301, and the inner or outer wall of the water inlet is provided with pipe threads, which are compatible with standard threaded connection pipe fittings, and can be connected to the external secondary water inlet pipe directly or through other elbows. The upper pipe port is the water outlet 302, which is connected and fixed to the lower end of the fixing frame 200 by mechanical connection methods such as embedded connection, snap connection, and screw connection.

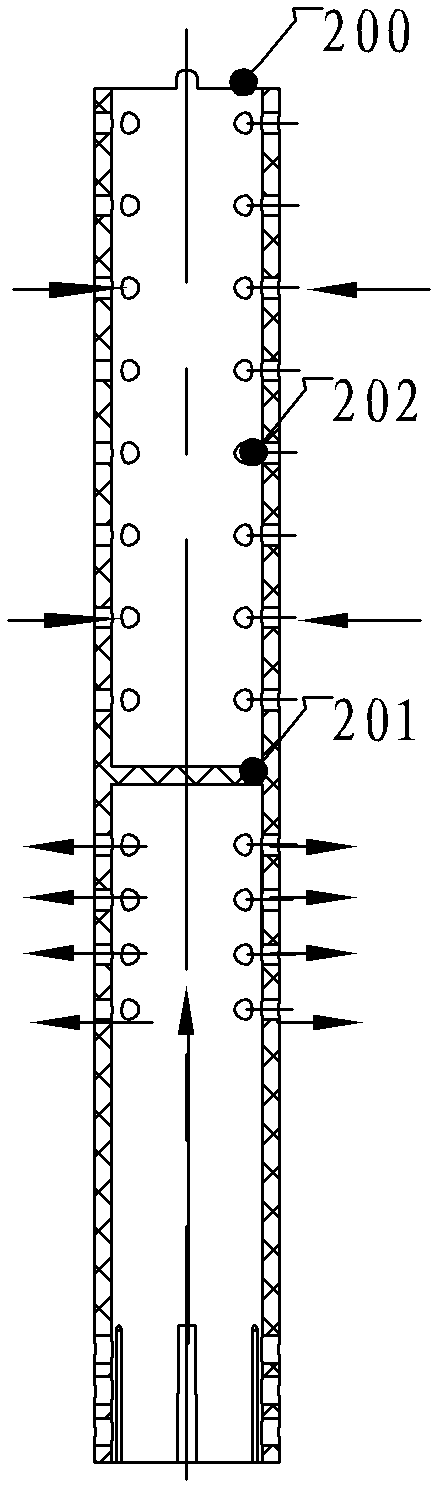

[0022] The fixing frame 200 has a cylindrical she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com