Box body of small gasoline engine

A gasoline engine and box technology, which is applied to engine components, machines/engines, cylinders, etc., can solve the problems of engine box heat dissipation performance, low exhaust emission standards, affecting engine life, and heavy cast iron cylinder liner quality. The effect of reducing the thermal form factor, improving the service life and reducing the phenomenon of cylinder pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

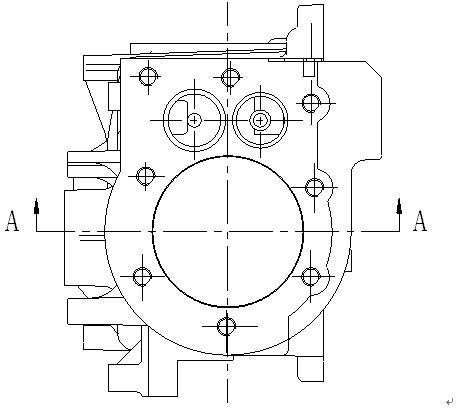

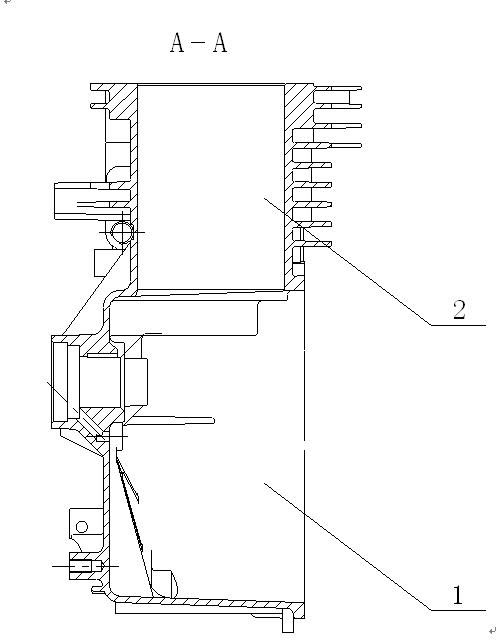

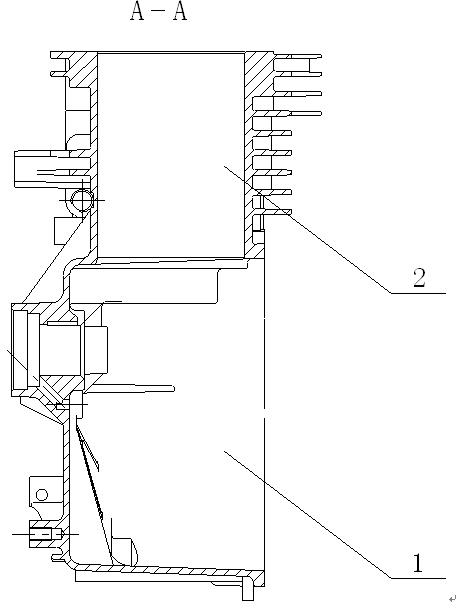

[0012] See figure 1 and figure 2 , the present invention provides a small gasoline engine casing, the casing is filled with one-shot die casting, the casing includes a crankcase 1 and a cylinder 2, and no cast iron cylinder is embedded in the cylinder 2 set.

[0013] Wherein, the material used for the box body is aluminum alloy, the proportion of alloy silicon in the said aluminum alloy material is 18%-20%, and the proportion of alloy copper is 6%-8%.

[0014] Wherein, the cylinder body 2 is finished by rolling mirror technology.

[0015] A small gasoline engine casing of the present invention adopts the above technical scheme, and the casing is filled with one-time molding die casting, and the ratio of alloy silicon in the aluminum alloy material is adjusted to 18%-20%, and the ratio of alloy copper to 6%. -8%, which increases the wear resistance of the box body and reduces wear; at the same time, because the cylinder block does not use cast iron cylinder liners, when fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com