chain tensioner

A chain tensioning device and chain technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve problems such as troublesome processing, and achieve the effect of easy processing and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

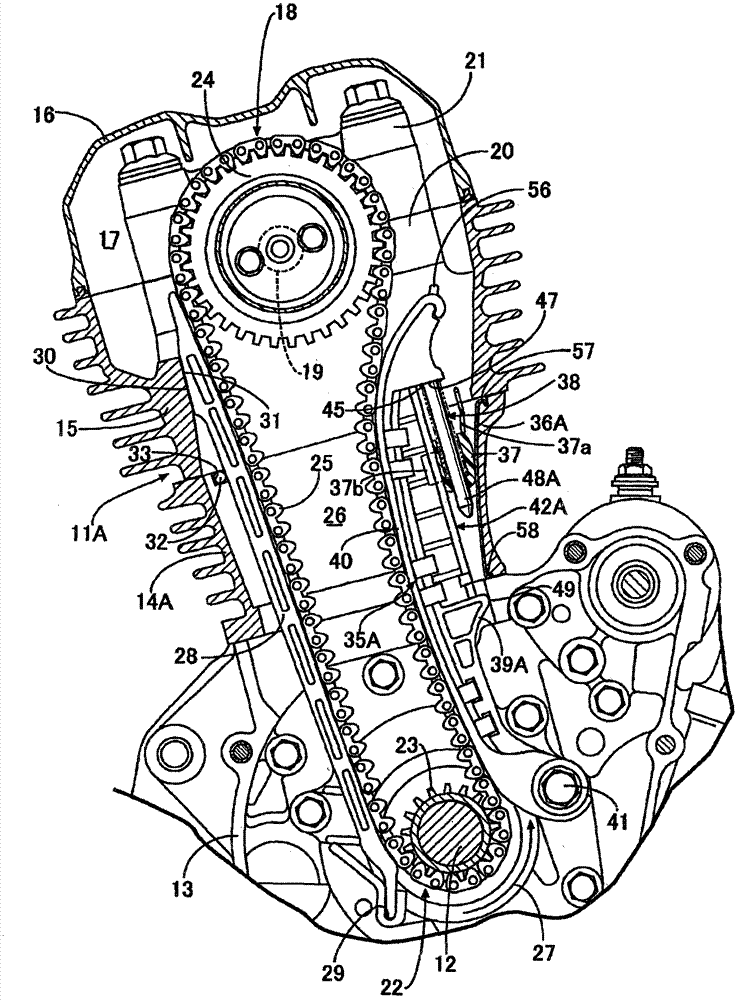

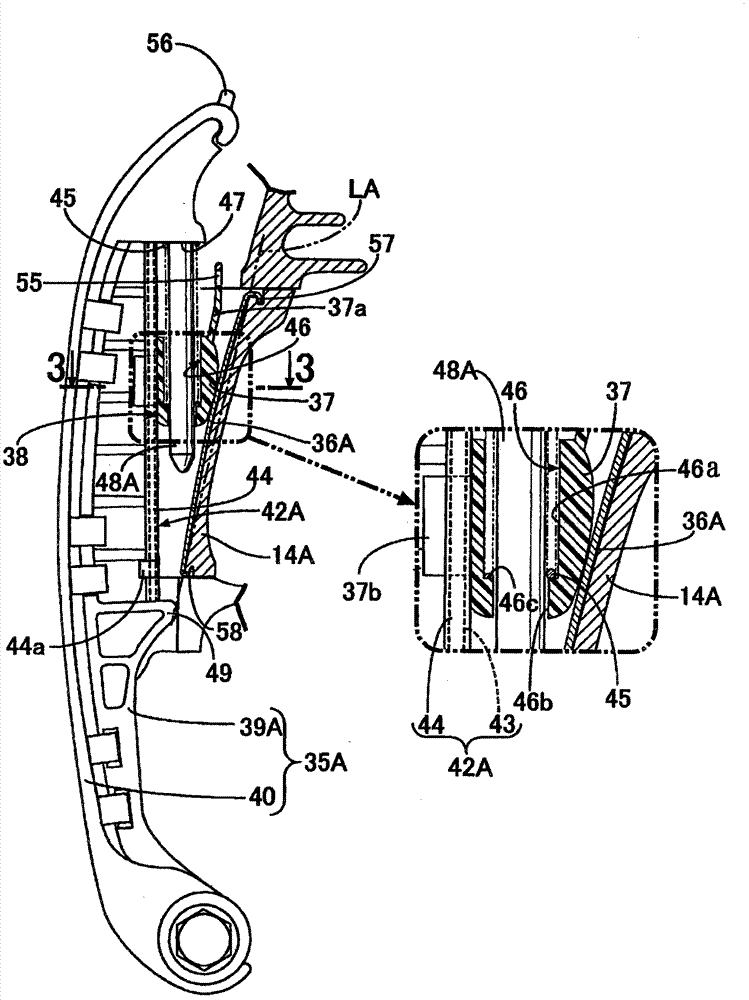

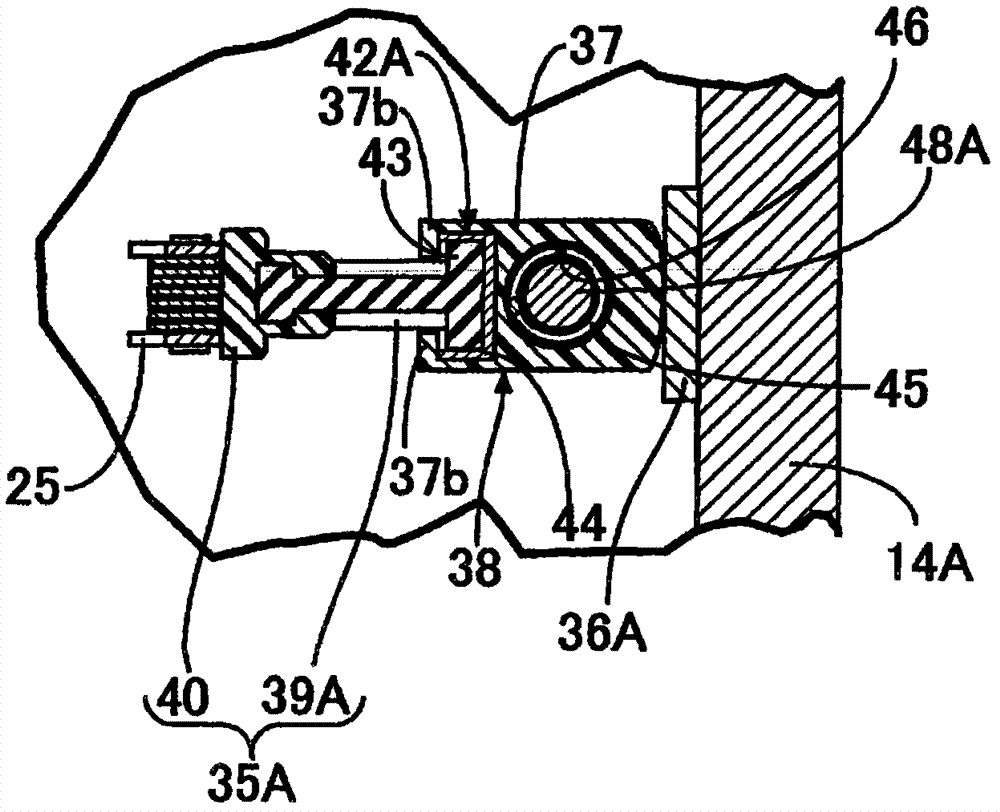

[0041] Refer below Figure 1 to Figure 5 A first embodiment of the present invention will be described. First, if figure 1 As shown, the engine involved in this embodiment is an engine equipped on a motorcycle, and its engine main body 11A has a crankcase 13, a cylinder assembly 14A, a cylinder head 15, and a cylinder head cover 16, wherein the crankcase 13 is rotatable The crankshaft 12 is supported on the ground, and the axis of the crankshaft 12 is consistent with the vehicle width direction of the motorcycle; the cylinder assembly 14A is connected with the crankcase 13 and is inclined forward and upward; the cylinder head 15 is connected with the cylinder assembly 14A; the cylinder head cover 16 It is connected with the above-mentioned cylinder head 15 to form a valve cavity 17 between it and the cylinder head 15 .

[0042] A valve mechanism 18 is housed in the valve chamber 17 . The valve mechanism 18 has a camshaft 19 whose axis is parallel to the above-mentioned crank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com