Pressure regulating valve, particularly for controlling a clutch in a motor vehicle automatic transmission

A technology of automatic transmission and pressure regulating valve, applied in the field of pressure regulating valve, can solve the problems of short reversing time and large flow, and achieve the effect of reducing axial force component and durable reversing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The functionally equivalent elements and dimensions in all the drawings also use the same reference symbols in different embodiments.

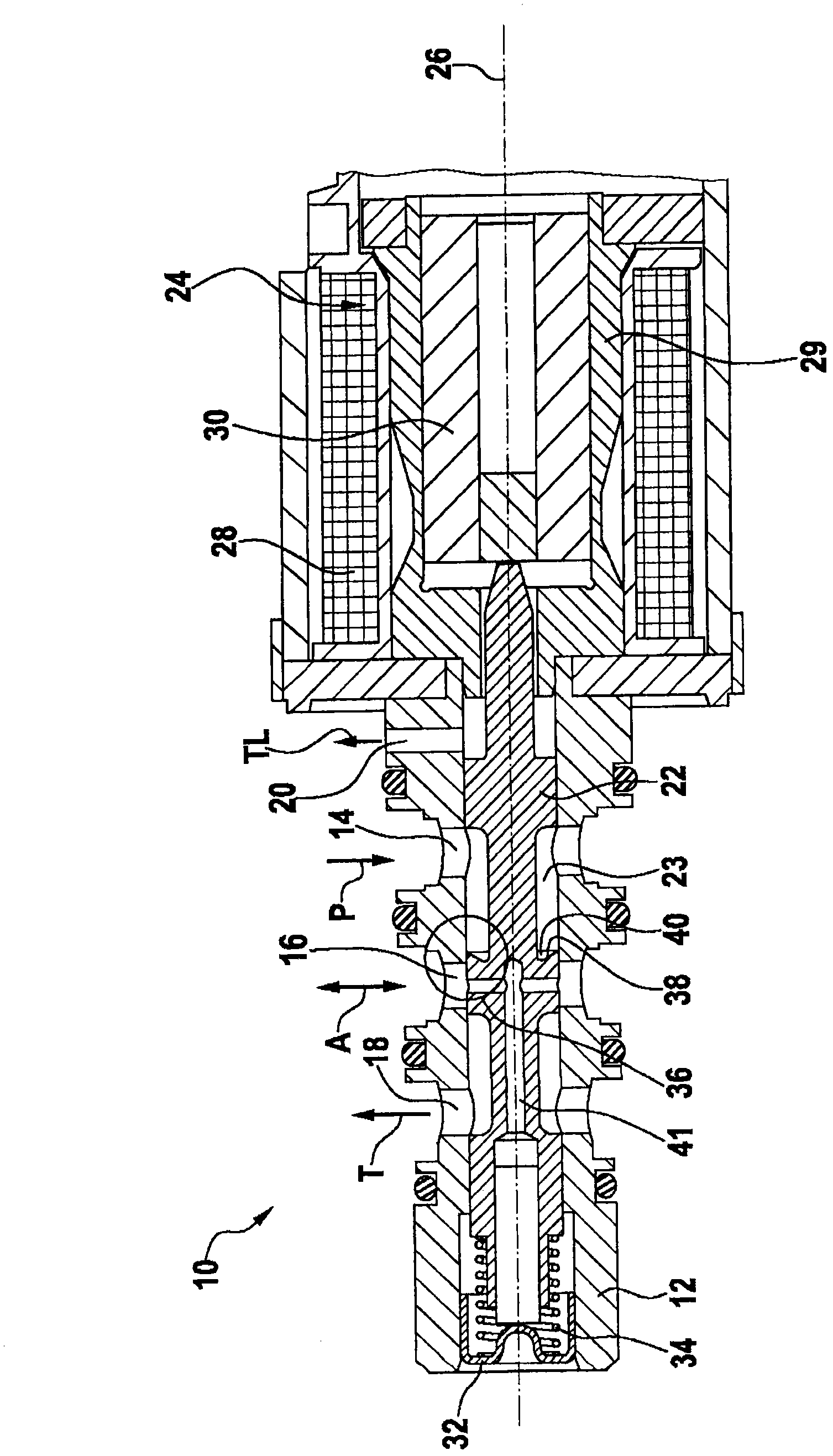

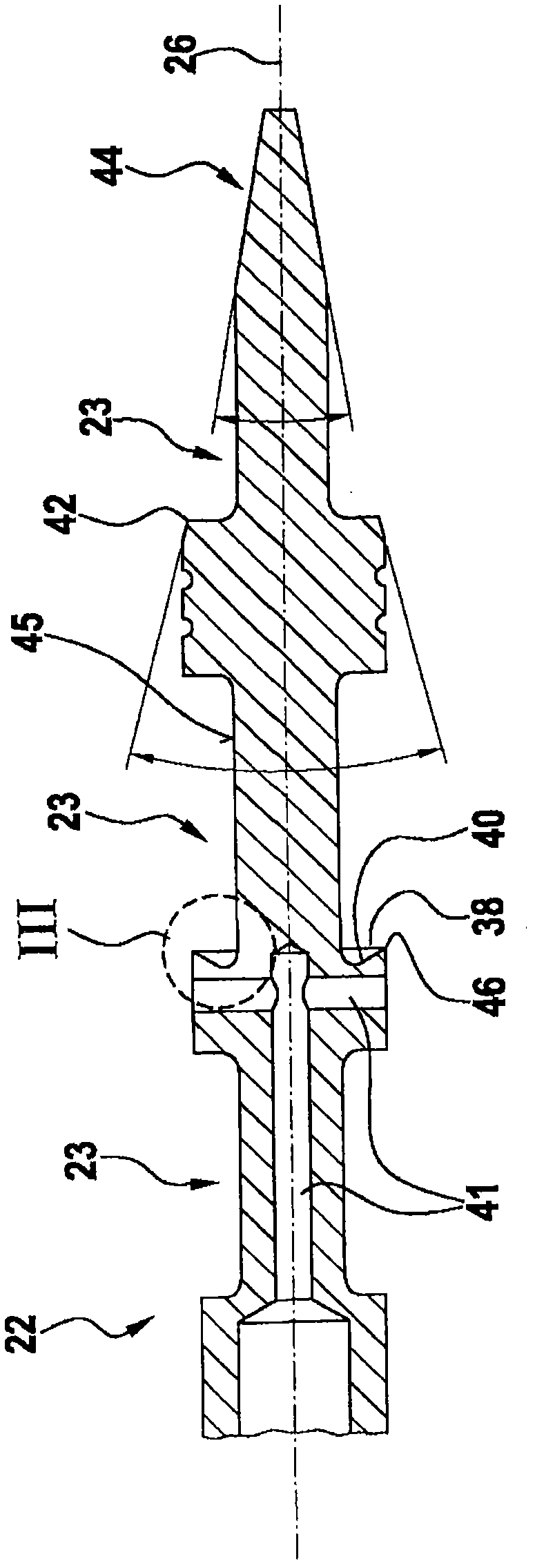

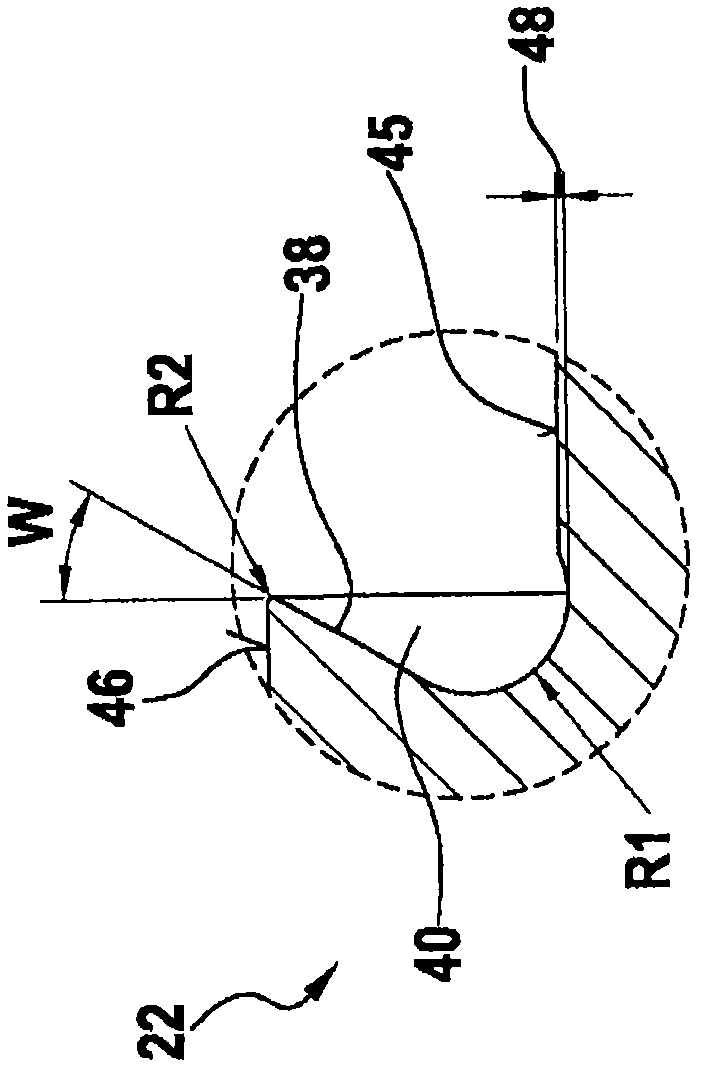

[0020] figure 1 A pressure regulating valve 10 for controlling a clutch in an automatic transmission of an automobile is shown in an axial sectional view. The pressure regulating valve includes a cylindrical housing 12 with a first transverse opening as a transverse hole 14 and a second transverse opening as a transverse hole 16, viewed in the direction of the longitudinal axis 26, spaced apart from each other (axial Distance), and has other horizontal holes 18 and 20. A valve core 22 coaxial with the housing 12 is provided in the housing 12. The valve core 22 can be moved axially by the electromagnet 24 in the direction of the longitudinal axis 26. The piston-like spool 22 now includes three grooves 23 extending in the direction of the longitudinal axis 26 ("axial extension"), which respectively extend in the form of annular grooves ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com