Oil tank water discharge liquid storage self force driving oil blocking device

A driving device and liquid storage technology, applied in the direction of valve operation/release devices, valve devices, engine components, etc., can solve the problems of increasing the amount of oil in the drainage process, complex structure, and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

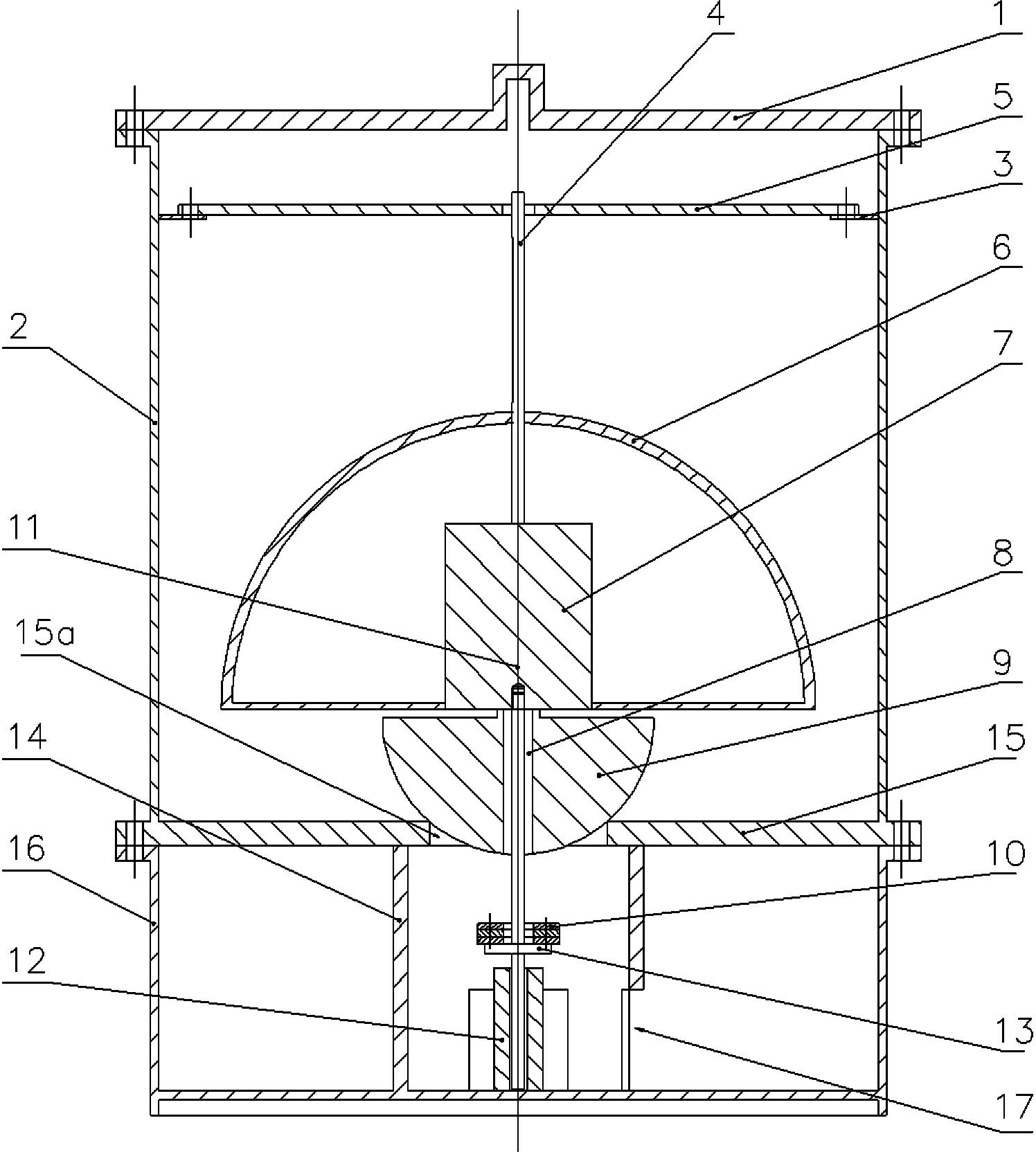

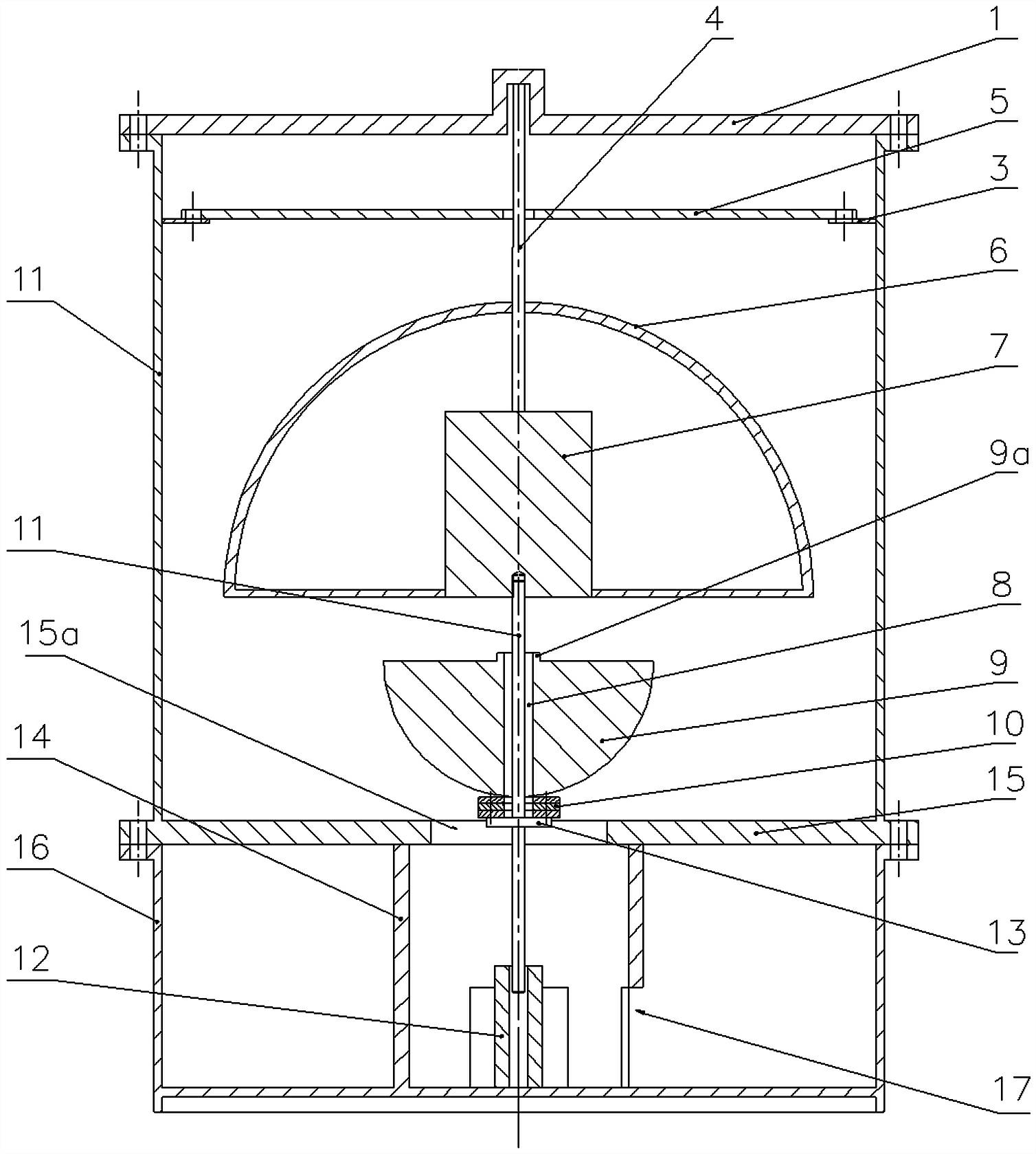

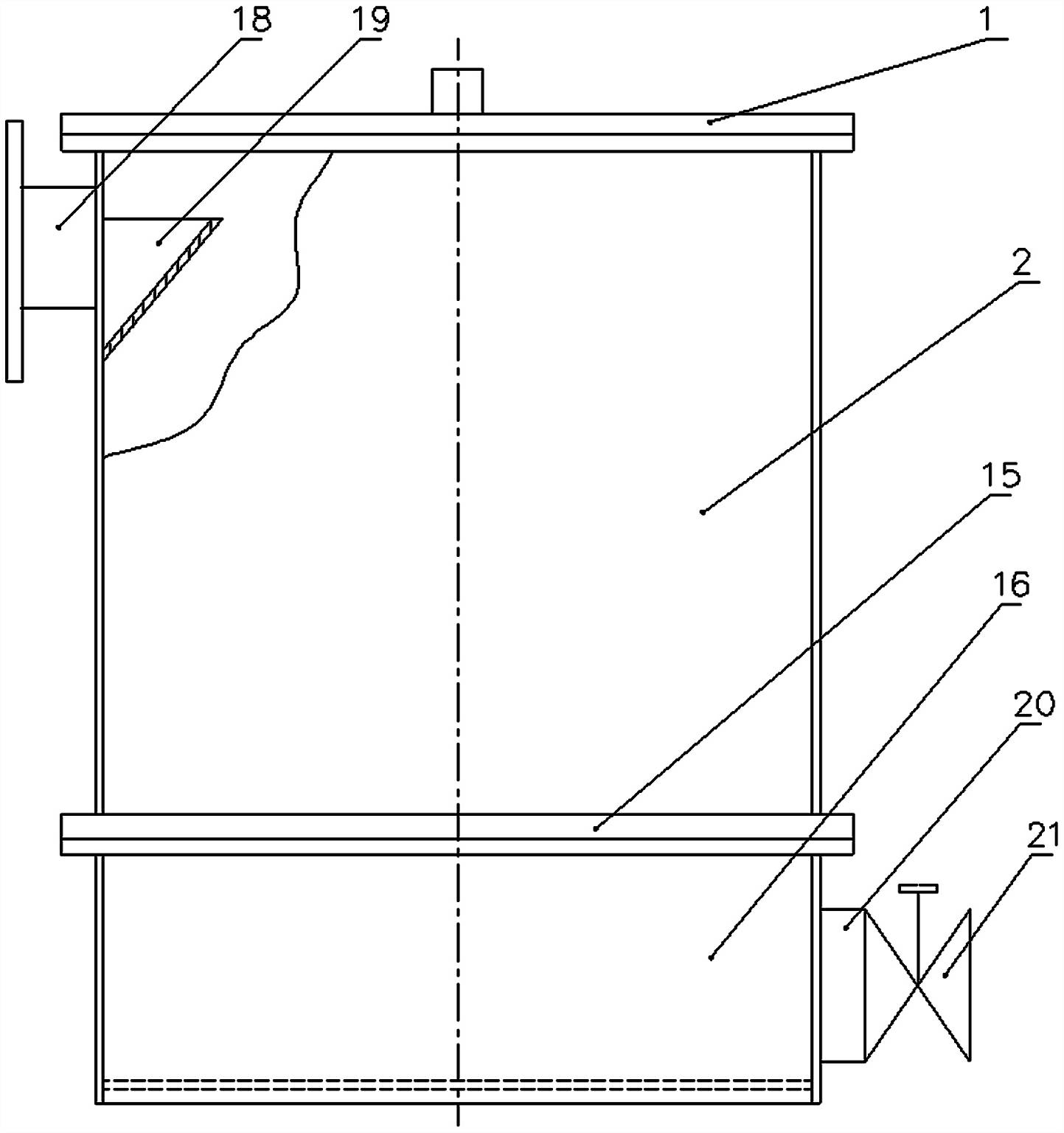

[0025] see figure 1 , figure 2, a liquid storage self-driven oil-repelling device for oil tank drainage, including a drain tank 16, a drain pipe 20 at the outlet of the drain tank 16 is equipped with a drain valve 21, and the bottom water entering the drain tank 16 can be discharged by opening the drain valve 21. The upper end of described drain tank 16 is provided with a liquid separation tank 2, and the upper end of liquid separation tank 2 is provided with case lid 1, and case lid 1 is fixedly connected with casing by bolt, and establishes sealing gasket sealing, opens case lid 1 and can divide liquid The inside of the box 2 is cleaned and maintained. The liquid inlet pipe 18 is provided on the upper part of the side wall of the liquid separation box 2, which is used to connect with the bottom pipe of the oil tank. The liquid inlet pipe 18 is fixed on the liquid separation box 2 by welding, or fixed on the liquid separation box 2 by flange connection . In order to avoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com