Plastic composite oil pipeline

An oil pipeline and plastic technology, applied in the field of fluid transportation and oil pipeline, can solve the problems of damage, decline in pipeline pressure resistance, leakage, etc., and achieve the effect of good leakage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

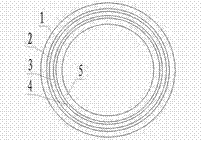

[0007] The plastic composite oil delivery pipe of the present invention is composed of a five-layer structure, the outer layer 1 is a polyethylene resin layer, the middle layer 2 is an adhesive resin layer, the middle layer 3 is a nylon resin layer, and the middle layer 4 is an adhesive resin layer. The inner layer 5 is a polyethylene resin layer.

[0008] The material of the adhesive resin layer is polyethylene polymer modified by maleic anhydride and tackifying resin. The polymer has been widely used in the production of PA / EVOH, HDPE / PA and other high-barrier plastic bottles and pesticide bottles. It can provide strong adhesion and adhesion durability between layers.

[0009] The middle layer of the present invention adopts nylon resin, nylon resin is also called PA, which can withstand various strong acids and most organic solvents such as 70% ethanol and dichloromethane, and has stable chemical properties, so it can prevent oil from leaking out of the pipeline, It is su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com