Lamp with light source integrated with radiator and manufacturing method of lamp

A radiator, integrated technology, applied in the light source and radiator integrated lamps and their manufacturing fields, can solve the problems of large thermal resistance, short life of LED bulbs, and large heat conduction path from LED chips to radiators, etc. The effect of heat dissipation, prolonging service life and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

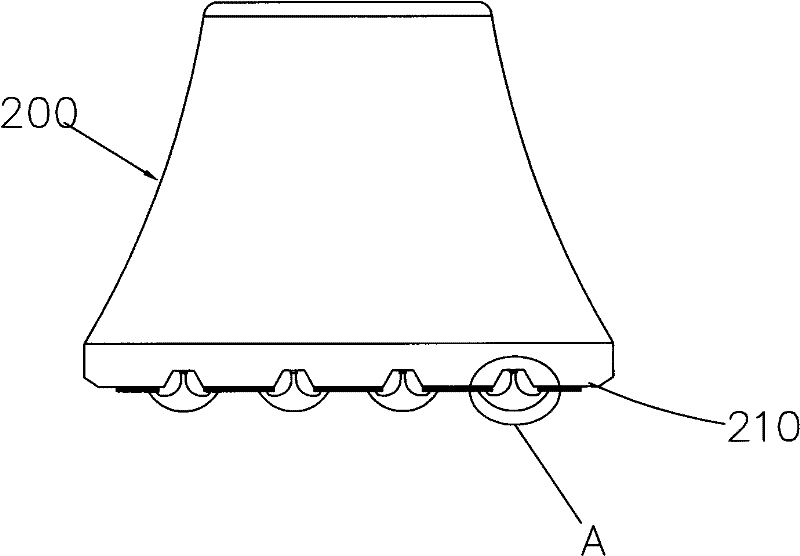

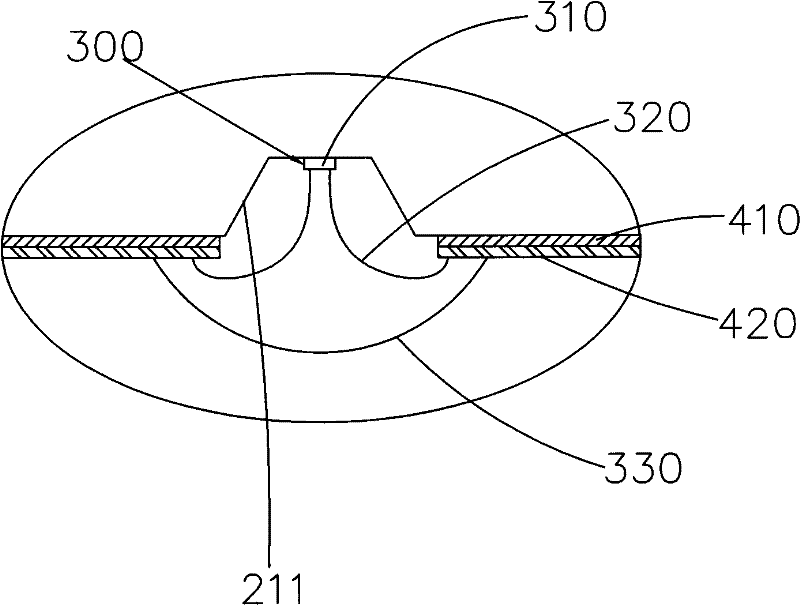

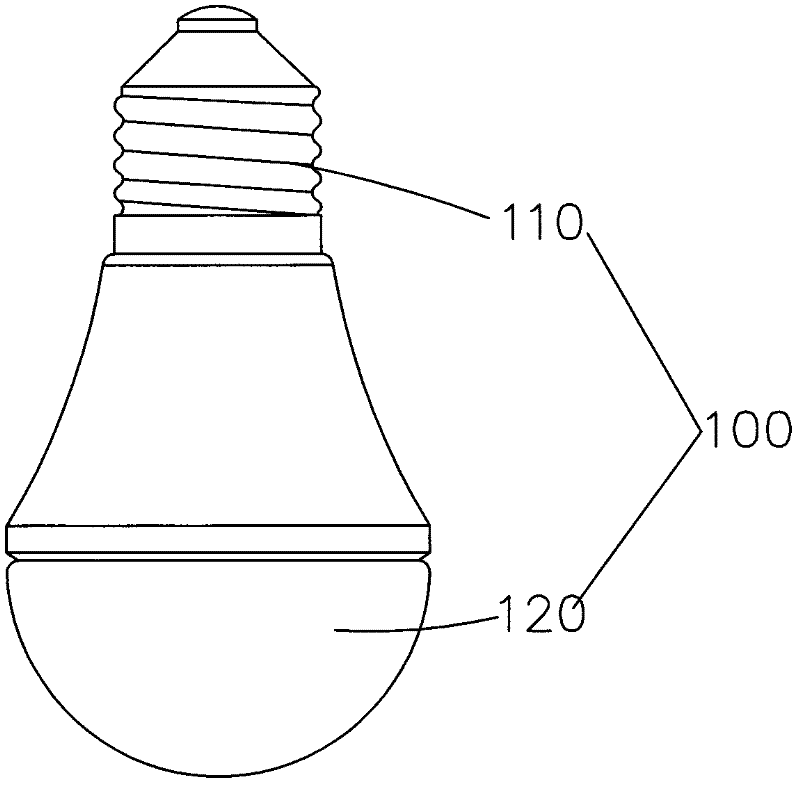

[0021] Such as Figure 1 ~ Figure 3 As shown, a light source and radiator integrated lamp provided by an embodiment of the present invention includes a housing assembly 100, a radiator 200 and a light source assembly 300, the radiator 200 is connected to the housing assembly 100, and the The light source assembly 300 includes an LED chip 310 , and the heat sink 200 includes a reflection plate 210 . In this embodiment, the reflection plate 210 is an end surface portion of the lower end of the heat sink 200 , and the reflection plate 210 is integrally formed on the lower end of the heat sink 200 . A reflective cup 211 for accommodating the LED chip 310 is disposed on the reflective plate 210 , and the reflective cup 211 may be in the shape of a recess. The LED chip 310 is fixedly arranged in the reflective cup 211 , and the LED chip 310 can be fixed in the reflective cup 211 by an encapsulation glue 330 such as die-bonding glue. An insulating layer 410 is disposed on the refle...

Embodiment 2

[0028] Such as Figure 1 ~ Figure 3As shown, the embodiment of the present invention provides a method for manufacturing a lamp integrated with a light source and a heat sink, comprising the following steps: setting a reflective cup 211 for accommodating the LED chip 310 on the reflective plate 210 of the heat sink 200, and An insulating layer 410 is disposed on the reflecting plate 210 , and then a circuit layer 420 is disposed on the insulating layer 410 , and the circuit layer 420 is used to supply power to the LED chip 310 . The heat sink 200 can be made of metal materials with good thermal conductivity such as aluminum alloy and copper, and the reflective plate 210 and the circuit layer 420 are separated by the insulating layer 410 , which has high reliability. Then place the LED chip 310 in the reflective cup 211 , and connect the LED chip 310 to the circuit layer 420 through the bonding wire 320 , and the bonding wire 320 connects the LED chip 310 to the circuit layer 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com