Measurement device of scanning probe

A measuring device and scanning technology, applied in the field of precision measurement, can solve the problems of friction influence, slow measurement speed, complex structure, etc., and achieve the effect of less interference, no friction influence, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

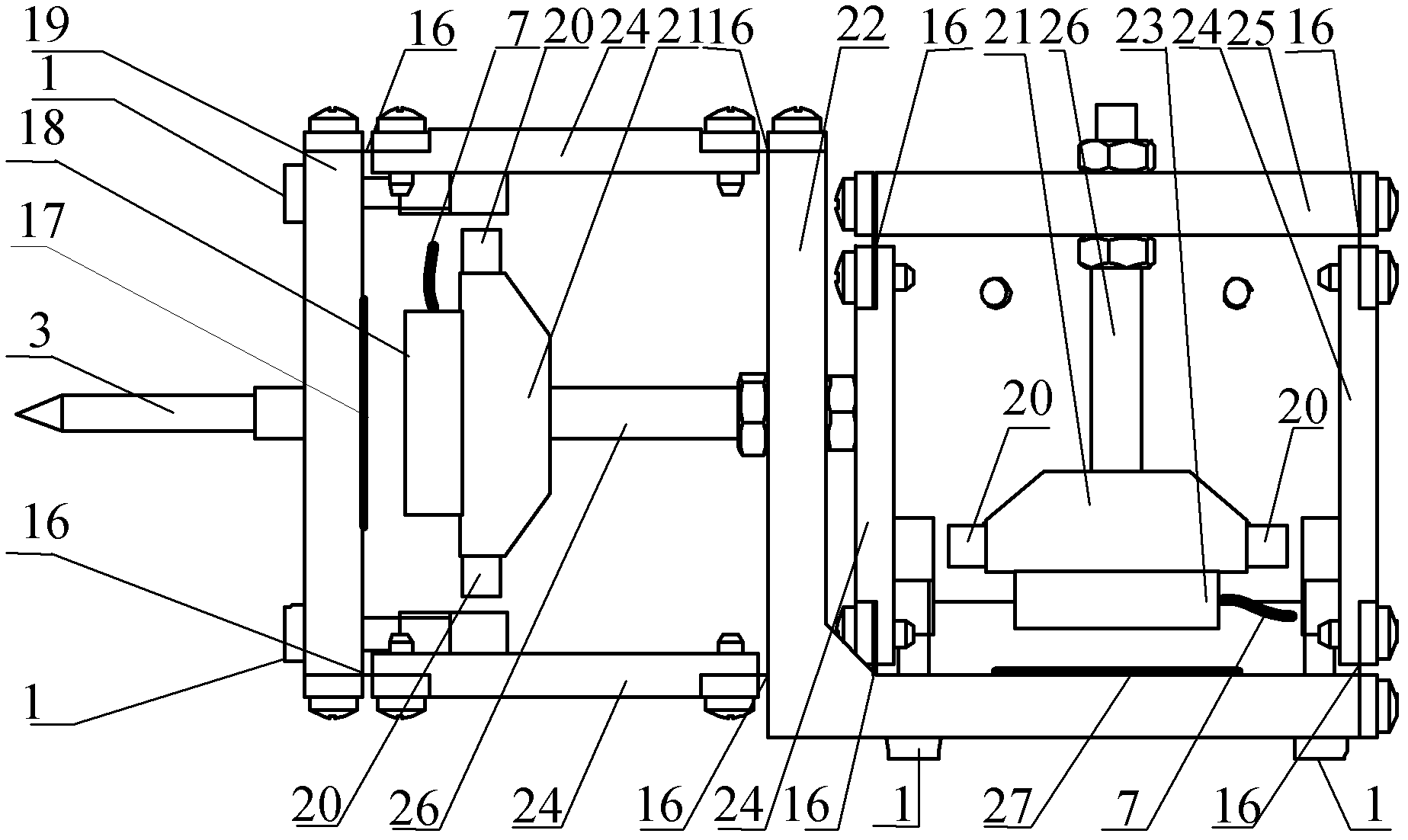

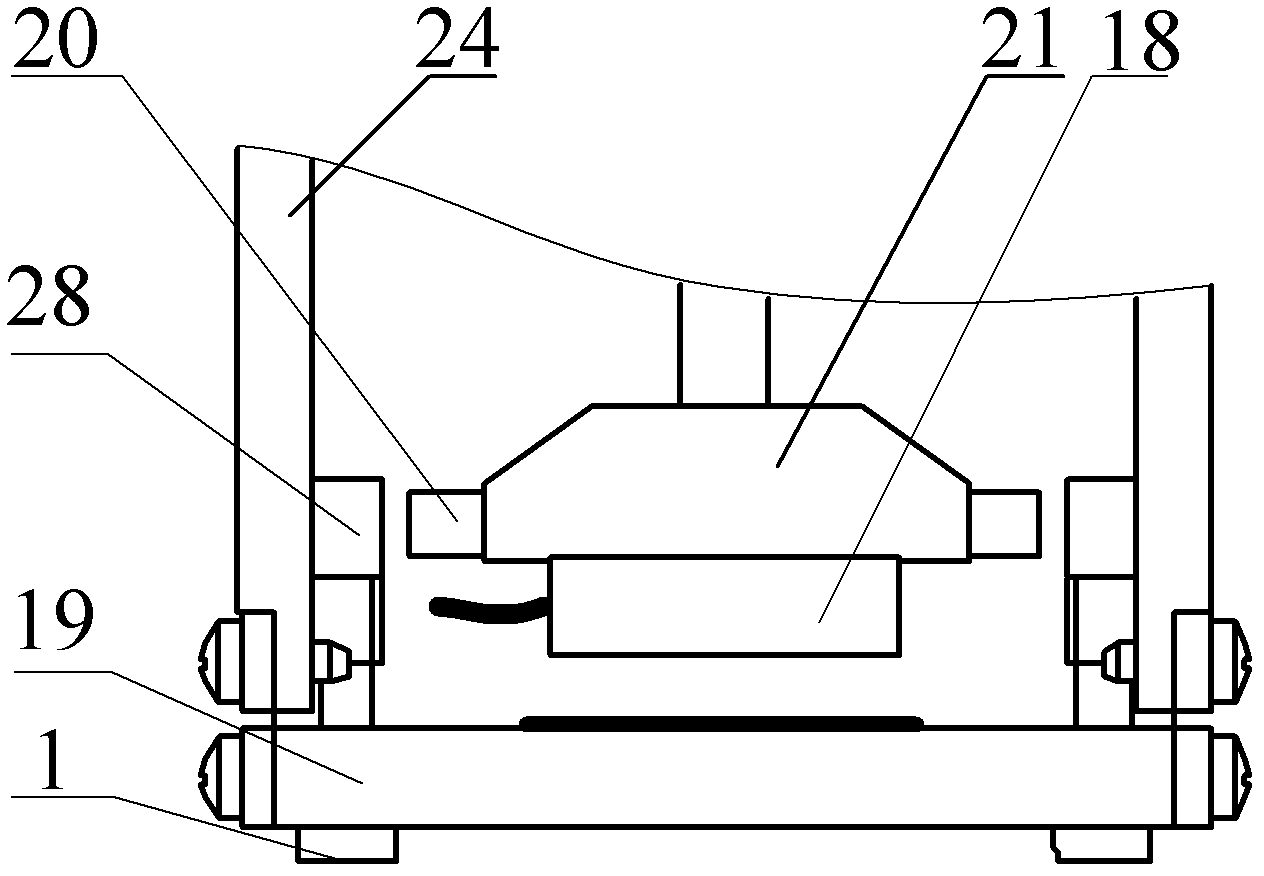

[0026] A scanning probe measurement device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

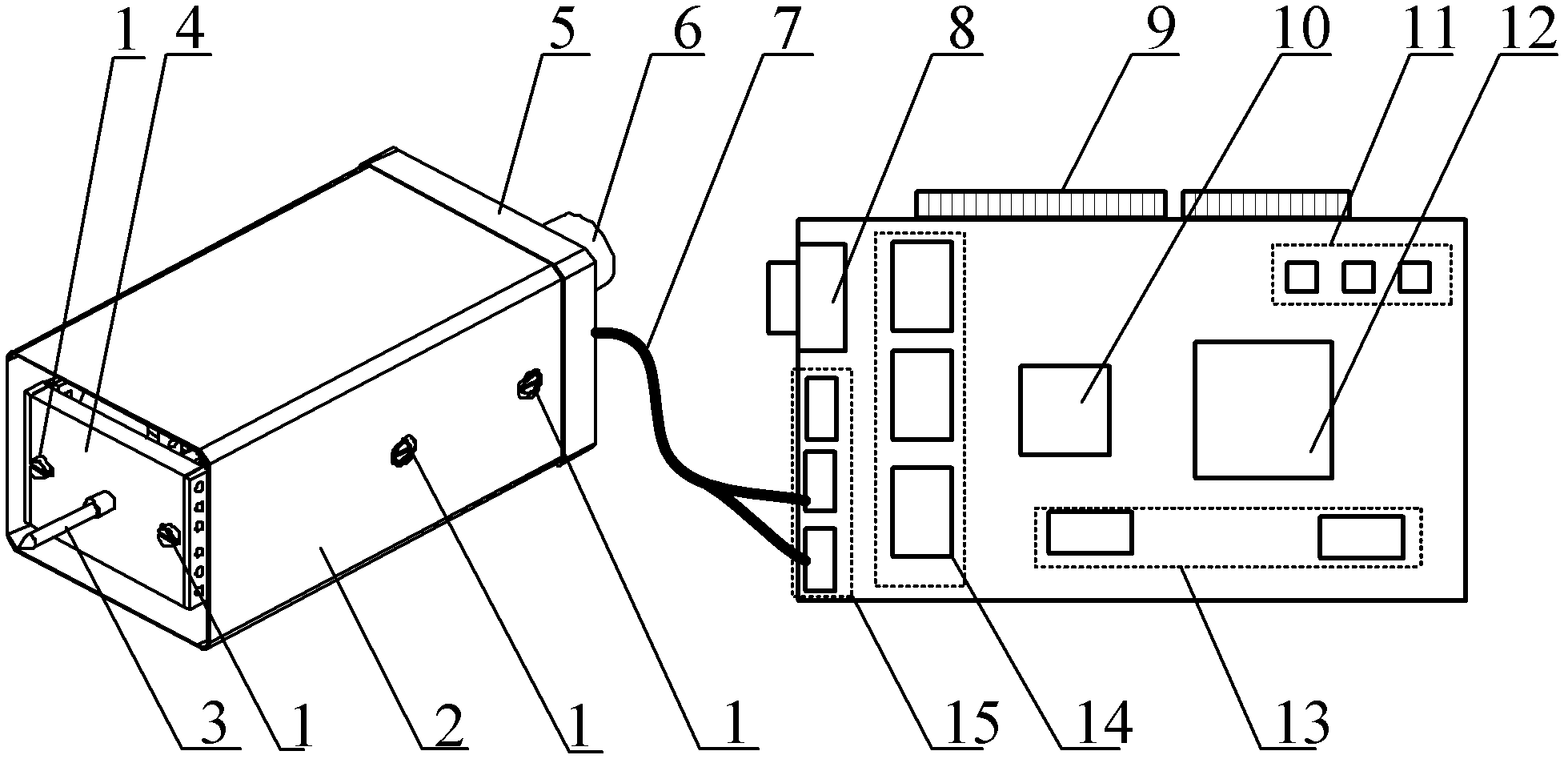

[0027] Such as figure 1 As shown, the entire raster scanning system is divided into two parts, the mechanical probe part and the raster signal processing part installed inside the computer host. The whole mechanical main body 4 is protected by the shell 2 and the back cover 5, the mechanical main body 4 is fixed on the shell 2 by screws, and the back cover 5 is designed with a mounting handle 6, which is convenient for the installation and use of the probe. The grating cable 7 used to transmit the grating signal is led out from the reserved hole on the back cover 5 of the probe, and connected to the grating signal interface 15 of the signal processing system. The grating signal processing system is distributed with a power conversion module 11, an amplification and shaping module 14, an FPGA module 12, and a DSP module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com