Short wave infrared laboratory spectrum calibration and correction method for hyper spectral imager

A short-wave infrared and spectral calibration technology, applied in the field of laboratory spectral calibration, can solve the problems of high spectral resolution of hyperspectral imagers, affecting the accuracy of radiation calibration coefficients, affecting the application accuracy of remote sensing images, etc., to avoid spectral lines Drift effects, measuring precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

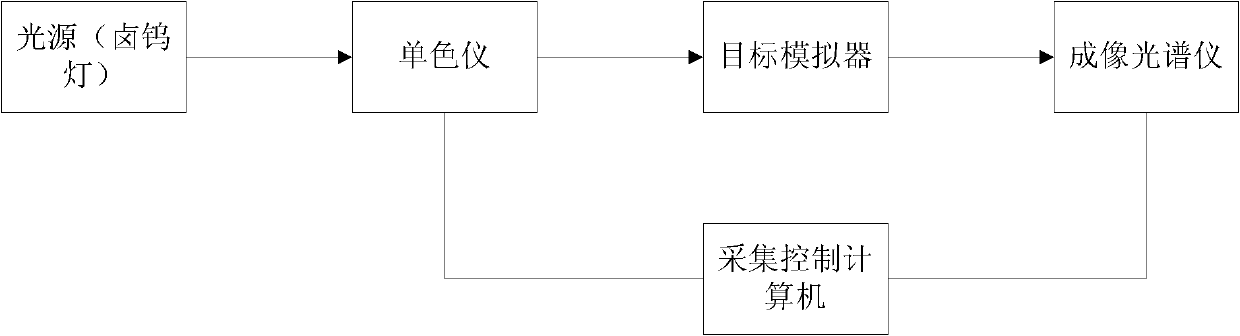

[0028] According to the invention, the spectral line drift correction for spectral calibration is performed on the short-wave infrared band of a dispersion-type hyperspectral imaging spectrometer. according to figure 1 Build a monochromator scanning method laboratory spectral calibration experimental device, adjust the experimental optical path, and ensure that the light from the monochromator imaging to the detector is uniform, stable, and straight. The light source is a 250W halogen tungsten lamp, and the adjusted voltage and current of the light source are: 11.3V / 5.13A. The controlled ambient temperature is 20±0.5°C and the humidity is 60%.

[0029] The details are as follows:

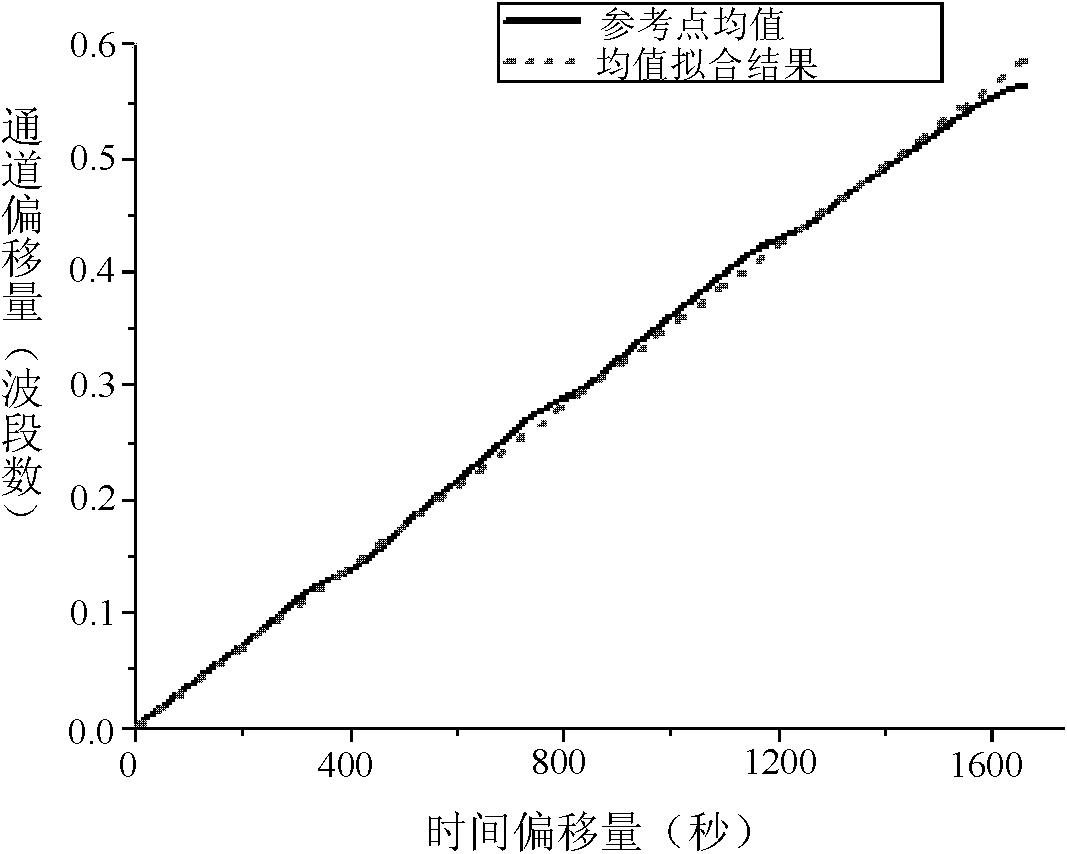

[0030] 1) Adjust the integration time of the imaging spectrometer to 3.6 milliseconds, and the angle of the pointing mirror to 1.885°. In the range of 1000-2500nm, the selected calibration bands are a(1190-1250nm), b(1600-1660nm), c(2330-2390nm), where a, b, and c correspond to the 15th, 29th and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com