Method for determining loading coaxiality by using vector method

A coaxiality and vector technology, which is applied in the field of calibrating loading coaxiality parameters of axial load testing machines for metal materials, can solve the problem that the loading coaxiality parameters cannot be measured, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

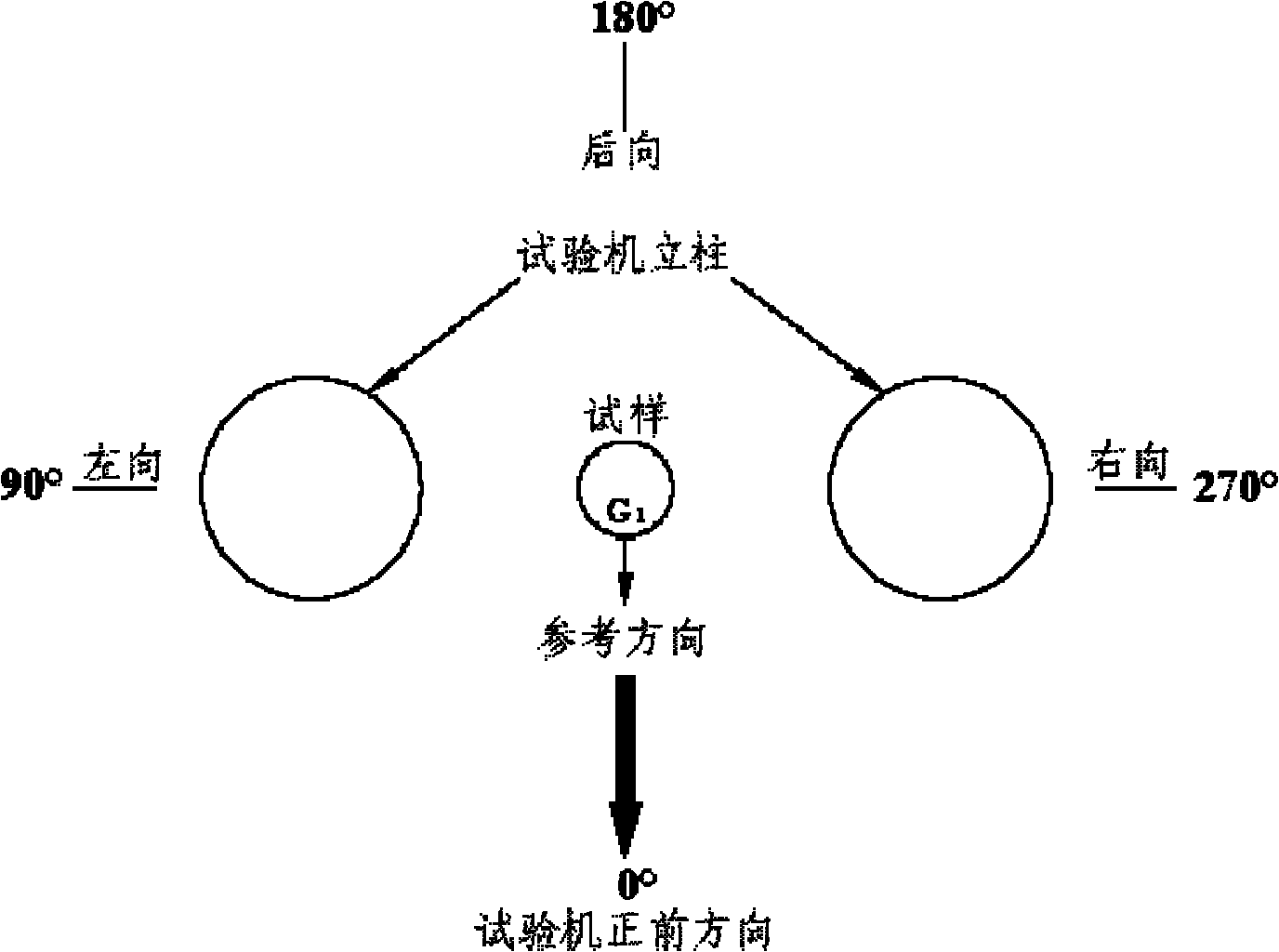

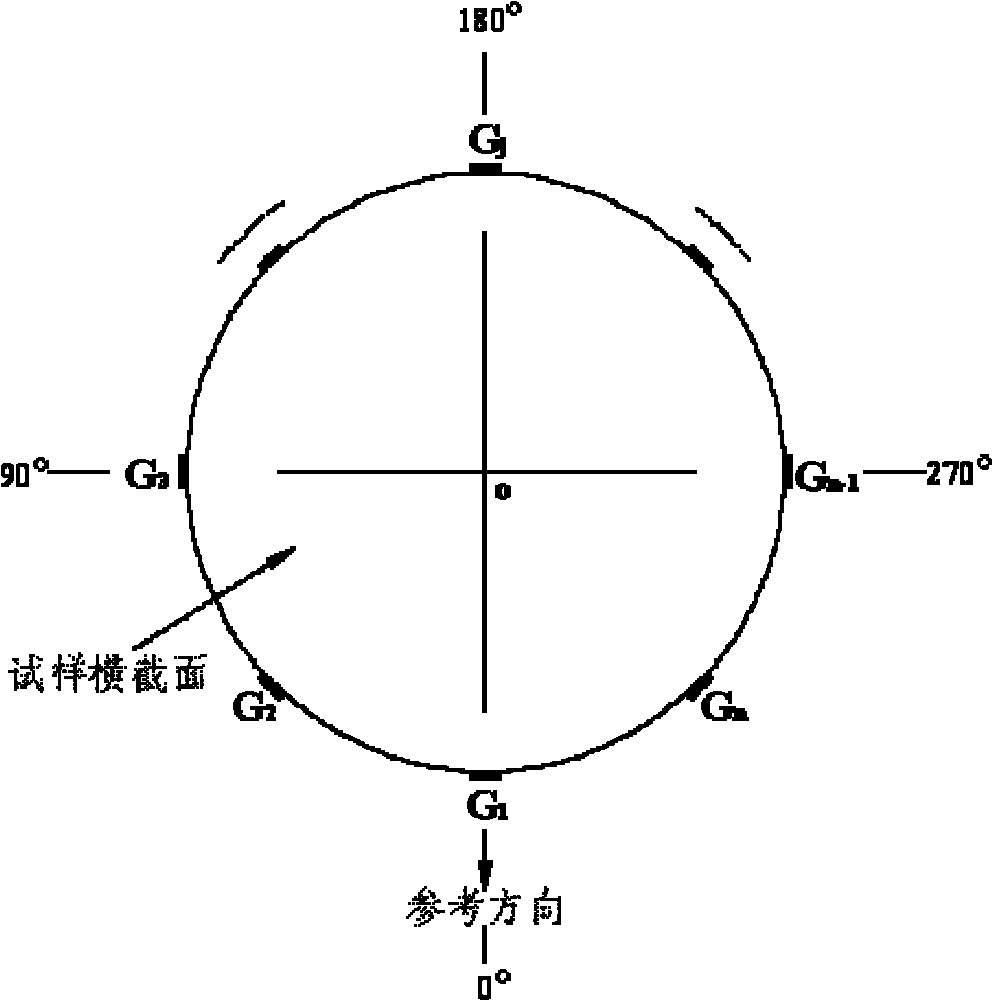

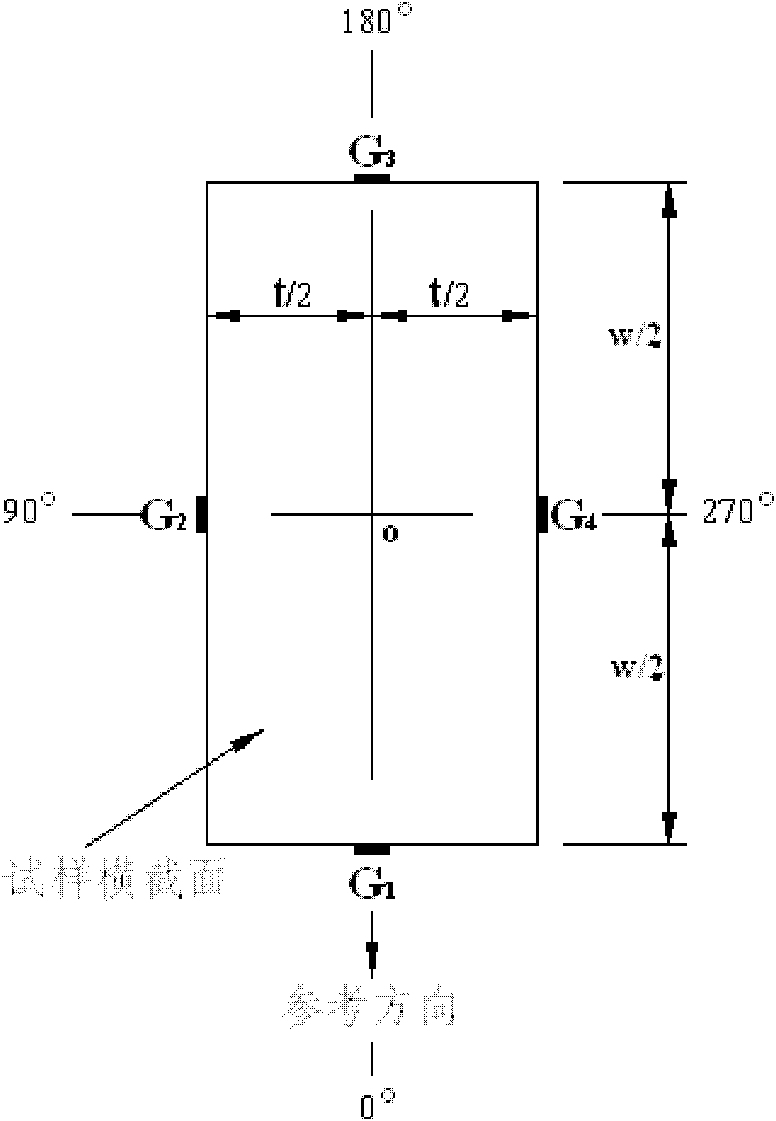

[0108] The practice of the present invention employs circular cross-section, thick rectangular cross-section and thin rectangular cross-section sensor coupons of different cross-sectional dimensions. The shape, size and clamping method of the sensor sample shall be the same or approximately the same as the actual application sample. The sensor sample should have a measuring point G on its head or shell 1 (strain gauge G 1 ) mark of the position and direction, so that when the sensor sample is clamped on the testing machine, this mark can be used to determine its orientation.

[0109]The entire strain measurement system consists of a strain gauge measurement system on the sensor sample, an automatic acquisition system for strain signals, a data processing and parameter calculation system, and an automatic control system. From measurement to result parameter calculation, it is completed by a computer and corresponding software. The strain measurement system consists of a resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com